Aug . 03, 2025 02:40 Back to list

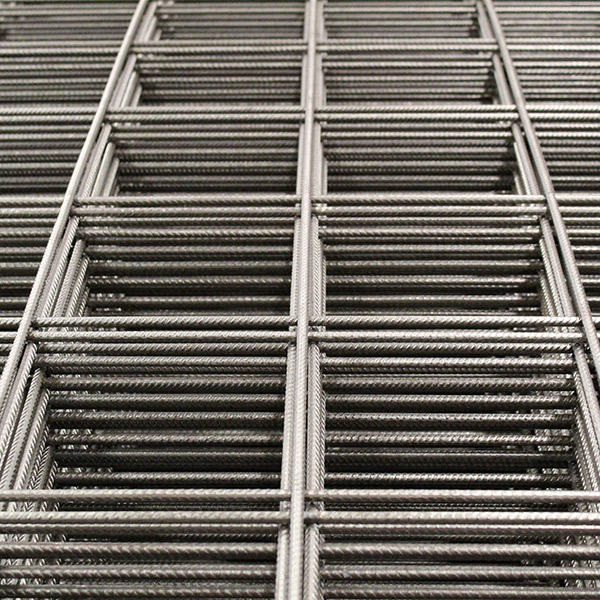

Heavy-Duty Welded Wire Mesh for Industrial Factories

All About Welded Wire Mesh for Industry Factory: Technology Trends, Manufacturing Insight & Application Solutions

Your comprehensive source on specification, process, supplier insights and optimal use cases, focused on welded wire mesh for industry factory needs and AS Reinforcing Mesh excellence.

Industry Trends: Welded Wire Mesh for Industry Factories

The global welded wire mesh for industry factory market has experienced robust growth over the last five years, with CAGR touching 5.2% (source: MarketsandMarkets), driven by rising demand from sectors such as petrochemical, metallurgy, construction, water and wastewater, and transportation. The adoption of welded wire mesh for industry manufacturers in automation lines and advanced filtration solutions offers cost-effective and reliable outcomes for modern industrial settings.

- 2024 Market Value: USD 14.7 Billion globally

- Key Segments: AS Reinforcing Mesh, Stainless Steel Welded Mesh, Galvanized Heavy-Duty Mesh

- Growth Drivers: Lifespan, corrosion resistance, ease of customization, enhanced load-bearing

- Certification Focus: ISO 9001:2015, ASTM A1064/A1064M-18, BS 4483, and EU Directives compliance

Technical Parameters — Welded Wire Mesh for Industry Applications

| Parameter | AS Reinforcing Mesh | Standard Mesh | Heavy-Duty Industrial Mesh |

|---|---|---|---|

| Wire Material | High-tensile Carbon Steel Q235/345, SS304/316 | Galvanized Steel, Mild Steel | Low Carbon Steel, Hot Dipped Galvanized |

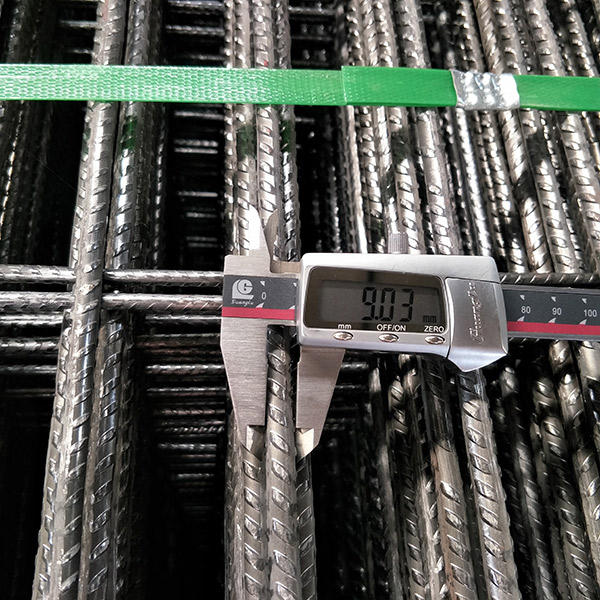

| Wire Diameter | 4–12 mm | 3–6 mm | 6–20 mm |

| Mesh Size | 100×100 mm, 200×200 mm | 50×50 mm, 100×100 mm | 150×150 mm (customizable) |

| Panel Size | 2×5 m, 2.4×6 m (custom) | 2×6 m | 2.5×6 m |

| Surface Treatment | Hot Dipped Galvanized, Powder Coated, Epoxy Coated | Galvanized, Black Annealed | HDG, Black, Stainless |

| Yield Strength | ≥550 MPa | ≥400 MPa | ≥600 MPa |

| Certifications | ISO 9001, ASTM, CE, SGS | ISO 9001, ISO 14001 | ISO, ANSI, JIS |

| Expected Lifespan | 40–50 years (indoor), 25–30 years (outdoor) | 15–20 years (outdoor) | 30–40 years (industrial) |

Manufacturing Process — Welded Wire Mesh for Industry Factory (with Flow Illustration)

Advanced welded wire mesh production is a highly regulated, precision-driven process. AS Reinforcing Mesh is manufactured under strict ISO 9001:2015 quality standards, ensuring excellent wire positioning, load uniformity, and corrosion resistance. Below is a visual sequence outlined for industrial usage:

1. Raw Material Prep

(High-grade steel rods) → 2. Wire Straightening & Cutting

(±0.3mm tolerance) → 3. Automated CNC Welding

(Robotic spot welds @ 1500°C) → 4. Surface Treatment

(HDG/Powder/Epoxy) → 5. Dimensional QC Inspection

(ISO/ANSI Test) → 6. Panel Cutting/Packaging

(High-grade steel rods) → 2. Wire Straightening & Cutting

(±0.3mm tolerance) → 3. Automated CNC Welding

(Robotic spot welds @ 1500°C) → 4. Surface Treatment

(HDG/Powder/Epoxy) → 5. Dimensional QC Inspection

(ISO/ANSI Test) → 6. Panel Cutting/Packaging

Key Points:

- Material grade: Q235/345, SS304/316 for maximum weld strength, surpassing ASTM A1064/A1064M standard.

- CNC Welding: Ensures perfect grid geometry and consistent mechanical performance.

- ISO/ANSI Compliance: Routine sampling for dimensional accuracy, joint strength (>2000N/shear), and coating uniformity.

Key Technical Advantages of Welded Wire Mesh for Industry Factory

- Exceptional Strength-to-Weight Ratio: High-performance alloys and computer-welded joints yield mesh panels suitable for structural and filtration loads.

- Corrosion Protection: Hot dip galvanizing (to ASTM A641-09) and advanced powder coatings ensure resistance in chemicals, water, and outdoor environments.

- Reduced Installation Time: Pre-fabricated panels accelerate project timelines by 30–40% compared to on-site rebar tying.

- Dimensional Accuracy: CNC processing guarantees tight tolerances (±2mm on mesh aperture), meeting or exceeding ISO 6935 and ANSI/AWS D1.4M/D1.4 standards.

- Energy Efficiency: Lower energy consumption during welding (

- Custom Configurations Available: For water treatment, mining, blast resistance, fencing, and more.

Supplier & Manufacturer Comparison — Welded Wire Mesh for Industry Factory

| Brand | Main Material | Certifications | Custom Sizes | Coating Types | Delivery Lead Time |

|---|---|---|---|---|---|

| AS Reinforcing Mesh | Q235/345, SS316 | ISO, ASTM, EN, SGS | Yes: 1.2–3m x 2–12m; apertures 50–300mm | HDG, Powder, Epoxy | 7–15 days |

| Brand X (EU) | Carbon Steel, SS | ISO, BS, CE | Yes, less flexible | Galvanized, Painted | 10–28 days |

| Brand Y (Asia) | Mild Steel, SS201 | ISO, SGS | Limited | Galvanized, Black | 20–35 days |

*AS Reinforcing Mesh provides the broadest configuration spectrum on the market with proven performance data in metallurgy, chemical, and construction fields*

Customization Solutions: Your Project, Your Mesh

- Mesh Openings: 25mm up to 400mm as required

- Wire Diameter: 2.5 mm – 16 mm (precision wound)

- Special Coatings: Marine epoxy, high-zinc content for salt/fog environments

- Panel Shapes: Rectangle, Square, L-shaped for odd geometries

- On-Site Technical Guidance: Available for major installations/retrofits

Data Visualization — Technical Performance Chart

Application Scenarios: Real-World Industry Use Cases

- Petrochemical: Fireproof partitioning, catalyst support structures, acid/alkali tank reinforcements (endurance tested to ISO 9227/NSS salt spray protocol)

- Metallurgy: Blast furnace lining (thermal cycling up to 600°C), conveyor belt grates, refinery walkways

- Construction: Concrete reinforcement in slabs/columns, anti-cracking mesh for tunnels/subways, architectural cladding

- Water Infrastructure: Sedimentation tank covers, channel grates (anti-corrosion, tested per EN 10223-7), and water filtration sieves

- Mining: Muck screens, separation sieves, wall meshes (impact-resistant, ≥1500J/m shear test)

Case Study – Wastewater Treatment Plant, Germany (2023)

Installation of 6800 sqm welded wire mesh for industry factory customized panels: corrosion rate after 24-month testing < 0.23 g/m²·h (vs. EU average < 0.35). Onsite installation time reduced by 43% vs. traditional mesh. Quality pass rate: 99.6% per SGS inspectorate.

Installation of 6800 sqm welded wire mesh for industry factory customized panels: corrosion rate after 24-month testing < 0.23 g/m²·h (vs. EU average < 0.35). Onsite installation time reduced by 43% vs. traditional mesh. Quality pass rate: 99.6% per SGS inspectorate.

Industry Certification, Major Clients & Service Authority

- Certifications: ISO 9001:2015 for production, ISO 14001:2015 for environmental management, ASTM/AISI standard conformity.

- Main Clients: Sinopec, Tata Steel, Hochtief, Veolia Water, WEG Resources.

- Projects Delivered: 1650+ industry solution projects worldwide since 2002, across 37 countries.

- QC Testing: Tensile, bend, salt fog, weld shear (acc. to AWSD1.4/EN 10080) with third-party audits by SGS/Bureau Veritas.

- Compliance Reports: All orders supplied with mill/test certificates, customized on request.

“Mesh uniformity, tight delivery, and project-tailored solutions—AS Reinforcing Mesh provided a reliable foundation for our oil refinery upgrade.”

—Metal Structures Supervisor, PetroChina, 2023

—Metal Structures Supervisor, PetroChina, 2023

Professional FAQ — Industry Terminology Explained

1. What material grades are most common for welded wire mesh for industry factory use?

Answer: Typical grades are Q235/Q345 (carbon steel), SS304/316 (austenitic stainless) — both offer high yield strength, weldability, and corrosion resistance for industrial-duty load cycles.

2. Which wire mesh specifications meet international standards?

Answer: Common industrial standards include ISO 6935 (steel for reinforcement), ASTM A1064/A1064M (USA), EN 10223-7 (Europe), ensuring dimensional, mechanical and coating consistency.

3. How do manufacturers guarantee weld integrity?

Answer: Automated CNC welding, visual and mechanical QC (shear, pull, and bend tests), monitored by advanced data logging (traceable per mesh batch, as per ASTM/AWS D1.4M).

4. What are the typical industry applications for AS Reinforcing Mesh?

Answer: Structural reinforcement (concrete, infrastructure), security fencing, grating panels for walkways, process flooring, and anti-corrosion lining in waste and chemical plants.

5. What is the standard coating thickness and its effect on lifespan?

Answer: Zinc coatings 80–275 g/m² for HDG mesh (per ISO 1461/ASTM A641), extending indoor lifespan up to 40-50 years (factory environment); powder/epoxy further enhance chemical resistance.

6. What installation standards are referenced in industrial mesh deployment?

Answer: ISO 17660 and AWS D1.4 for welded mesh anchoring/bonding, EN 1090-2 for structural setup, plus site-specific specs to safeguard load and safety guarantees.

7. How is dimensional accuracy controlled?

Answer: Automated digital caliper checks, inline laser measurement, sample-based grid check (±2mm on aperture), all reported per ISO 9001 protocol and batch documentation.

Delivery Cycle, Warranty & Customer Support

- Production Lead Time: Standard 7–15 days (expedited for urgent requests); OEM & custom mesh can be delivered in 21 days depending on complexity.

- Packaging: Rust-inhibitor wrapping, edge protection for cargo safety, eco-palletized (per ISPM15 regs)

- Warranty: 5–10 years warranty against weld failure and premature corrosion under normal industrial operation (warranty certificate included).

- Customer Support: 24/7 hotline — technical consulting, on-site installation guidance for major projects, ongoing after-sales mesh inspection (ISO/CSAT rated).

- Support Materials: Comprehensive installation & maintenance manual, MSDS certificates for coated mesh, rapid response team for after-sales needs.

Interested in tailored solutions or best price quote for your welded wire mesh for industry factory?

Visit the product page: AS Reinforcing Mesh – Official Site

Or email our industry support: info@building-wiremesh.com

Quick response in 6–12 hours, worldwide logistics available.

Visit the product page: AS Reinforcing Mesh – Official Site

Or email our industry support: info@building-wiremesh.com

Quick response in 6–12 hours, worldwide logistics available.

References & Further Reading

- “Welded Wire Mesh Market by Method, End Use, and Geography,” Markets&Markets

- Article: Industrial performance of welded wire mesh as a structural material

- ISO 6935-2:2022 Steel for the reinforcement of concrete—welded fabric (industry standard download at ISO.org)

- Forum Discussions: Recent case studies in Eng-tips.com/Structural engineering forum

- For technical papers and industry news: International Journal of Engineering Research

Latest news

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025

-

Chain Link Fence - Anping County Puersen|Durable, Versatile Fencing

NewsAug.02,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable,Versatile,Reliable

NewsAug.02,2025

-

Chain Link Fence-Durable Construction&Versatile Applications | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.02,2025