កុម្ភៈ . 13, 2025 09:15 Back to list

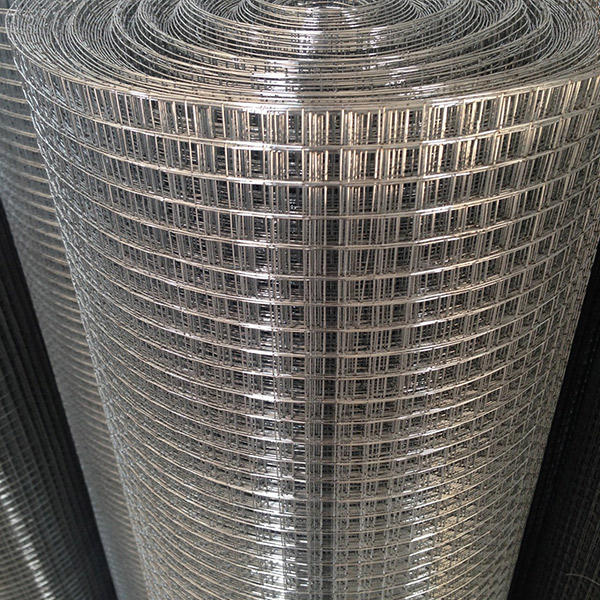

wholesale good quality reinforcing mesh

In the world of construction and infrastructure development, the demand for high-quality reinforcing mesh cannot be overstated. These essential materials provide the necessary structural integrity to concrete and masonry projects, ensuring safety, durability, and longevity. This article explores the profound impacts and considerations surrounding wholesale good quality reinforcing mesh and why it’s a critical choice for engineers, architects, and construction experts around the world.

The importance of trustworthiness in choosing a wholesale supplier of reinforcing mesh cannot be emphasized enough. A trusted supplier is characterized by consistent delivery schedules, transparent pricing structures, and, crucially, the source material's provenance. Knowing where and how the raw materials were sourced, and their environmental impact, adds to the social trust and ethical construct of the supplier. This trust is critical in today’s construction industry, where project margins are as closely scrutinized as build quality. While cost is a decisive factor, experienced engineers understand that lower initial costs at the expense of quality can have expensive long-term repercussions, such as increased maintenance costs or premature failures. Investing in good quality reinforcing mesh eliminates these concerns, bringing peace of mind and ensuring greater ROI through the durability of the build. Additionally, from a sustainability perspective, high-quality reinforcing mesh, when produced and sourced responsibly, contributes significantly to environmentally conscious building practices. Quality materials reduce waste through longevity and resilience, and their use in construction reflects a deep commitment to sustainable development goals. By investing in reinforcing mesh that adheres to stringent environmental and ethical standards, one not only meets regulatory requirements but also contributes positively toward the global sustainability agenda. As construction projects grow in complexity and scale, the role of reinforcing mesh is even more pronounced. It is the backbone on which modern infrastructure relies. By choosing the correct type of mesh through careful consideration of its specifications, ensuring the authority and trustworthiness of suppliers, and recognizing the economic and environmental impacts of these decisions, stakeholders can lay the foundation for successful projects that stand the test of time. In summary, navigating the landscape of wholesale good quality reinforcing mesh necessitates a combination of experience, technical expertise, authority in supplier selection, and a comprehensive understanding of sustainability and trustworthiness. Balancing these factors is pivotal to securing safe, durable, and economically viable construction outcomes that meet both current and future demands.

The importance of trustworthiness in choosing a wholesale supplier of reinforcing mesh cannot be emphasized enough. A trusted supplier is characterized by consistent delivery schedules, transparent pricing structures, and, crucially, the source material's provenance. Knowing where and how the raw materials were sourced, and their environmental impact, adds to the social trust and ethical construct of the supplier. This trust is critical in today’s construction industry, where project margins are as closely scrutinized as build quality. While cost is a decisive factor, experienced engineers understand that lower initial costs at the expense of quality can have expensive long-term repercussions, such as increased maintenance costs or premature failures. Investing in good quality reinforcing mesh eliminates these concerns, bringing peace of mind and ensuring greater ROI through the durability of the build. Additionally, from a sustainability perspective, high-quality reinforcing mesh, when produced and sourced responsibly, contributes significantly to environmentally conscious building practices. Quality materials reduce waste through longevity and resilience, and their use in construction reflects a deep commitment to sustainable development goals. By investing in reinforcing mesh that adheres to stringent environmental and ethical standards, one not only meets regulatory requirements but also contributes positively toward the global sustainability agenda. As construction projects grow in complexity and scale, the role of reinforcing mesh is even more pronounced. It is the backbone on which modern infrastructure relies. By choosing the correct type of mesh through careful consideration of its specifications, ensuring the authority and trustworthiness of suppliers, and recognizing the economic and environmental impacts of these decisions, stakeholders can lay the foundation for successful projects that stand the test of time. In summary, navigating the landscape of wholesale good quality reinforcing mesh necessitates a combination of experience, technical expertise, authority in supplier selection, and a comprehensive understanding of sustainability and trustworthiness. Balancing these factors is pivotal to securing safe, durable, and economically viable construction outcomes that meet both current and future demands.

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025