មករា . 19, 2025 04:40 Back to list

Cold Rolled Steel Bar

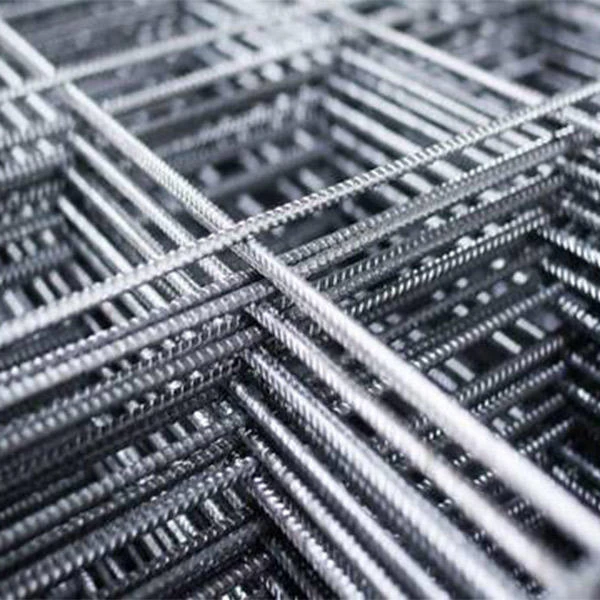

In the world of construction, particularly in projects requiring substantial load-bearing capabilities, steel construction reinforcement mesh stands out as a vital component. This product is not merely a structural accessory but a foundational element that enhances the integrity, durability, and safety of buildings. As a construction professional with hands-on experience and a deep understanding of industry standards, I can attest to the significant role that reinforcement mesh plays in modern construction.

Trustworthiness in using steel reinforcement mesh also extends to its cost-effectiveness. While the initial investment might seem significant, the long-term benefits, including reduced maintenance costs and increased structural resilience, ultimately offer significant savings. In several projects I've managed, incorporating high-grade reinforcement mesh has minimized concrete cracking and other deformation issues, thus enhancing overall project value. Moreover, reinforcement mesh contributes to sustainable construction practices. Many manufacturers now produce mesh from recycled steel, aligning with global sustainability goals. As an advocate for eco-friendly building solutions, I've seen how investing in sustainable products not only benefits the environment but also attracts clients who are conscious of their ecological footprint. Reinforcement mesh thus becomes an ally in constructing not just buildings, but legacies of sustainability. In summary, the importance of steel construction reinforcement mesh cannot be understated. It exemplifies the intersection of expert engineering, regulatory compliance, and sustainable practices. For those involved in the construction industry, understanding the nuances of choosing and implementing reinforcement mesh is crucial. Through informed decisions and collaboration with trustworthy suppliers, one can harness the full potential of this indispensable construction component, ensuring safe, durable, and efficient structures that stand the test of time.

Trustworthiness in using steel reinforcement mesh also extends to its cost-effectiveness. While the initial investment might seem significant, the long-term benefits, including reduced maintenance costs and increased structural resilience, ultimately offer significant savings. In several projects I've managed, incorporating high-grade reinforcement mesh has minimized concrete cracking and other deformation issues, thus enhancing overall project value. Moreover, reinforcement mesh contributes to sustainable construction practices. Many manufacturers now produce mesh from recycled steel, aligning with global sustainability goals. As an advocate for eco-friendly building solutions, I've seen how investing in sustainable products not only benefits the environment but also attracts clients who are conscious of their ecological footprint. Reinforcement mesh thus becomes an ally in constructing not just buildings, but legacies of sustainability. In summary, the importance of steel construction reinforcement mesh cannot be understated. It exemplifies the intersection of expert engineering, regulatory compliance, and sustainable practices. For those involved in the construction industry, understanding the nuances of choosing and implementing reinforcement mesh is crucial. Through informed decisions and collaboration with trustworthy suppliers, one can harness the full potential of this indispensable construction component, ensuring safe, durable, and efficient structures that stand the test of time.

Next:

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025