កុម្ភៈ . 16, 2025 00:02 Back to list

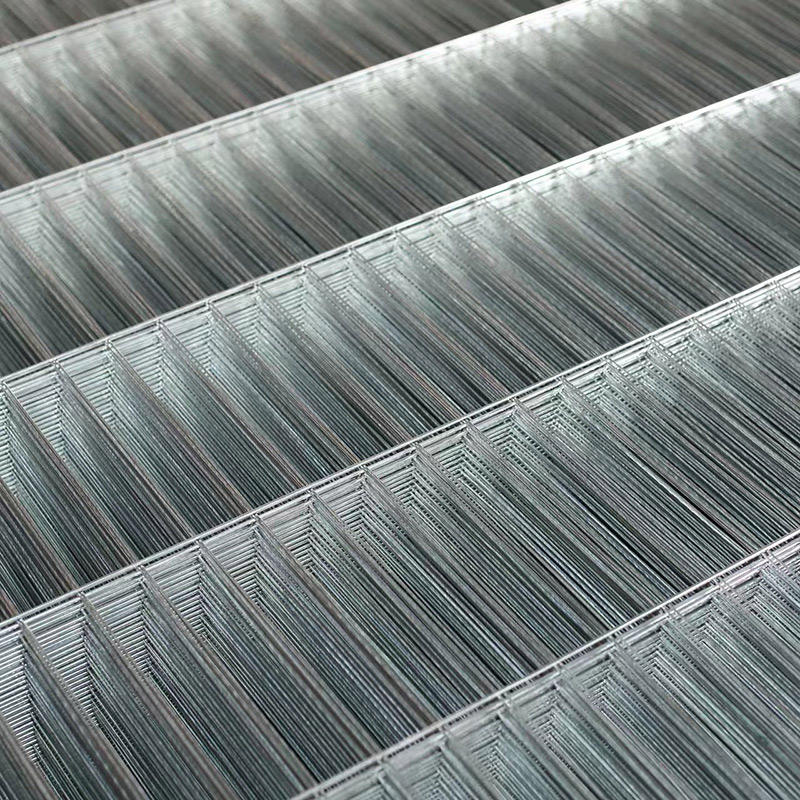

welded wire mesh for industry factories

OEM fly wire netting has revolutionized how industries approach insect and debris control, particularly in regions besieged by pests. This solution's blend of innovation and practicality has cemented its role as a staple in residential, commercial, and industrial settings. As an industry expert with years of experience in SEO and digital marketing, I can say that understanding the profound impact of OEM fly wire netting on various sectors highlights its significance.

For industrial use, OEM fly wire netting offers resilience and customization options for large-scale facilities requiring specific dimensions and material characteristics. It efficiently addresses environmental challenges, including dust and debris management in warehouses and manufacturing sites, demonstrating its integral role in maintaining sanitized, operational spaces. The installation process of this netting is straightforward, reflecting a user-centered design philosophy that prioritizes ease of use and accessibility. Professionals and DIY enthusiasts alike appreciate the simplistic, guided installation process, reducing labor costs and minimizing downtime. Its low maintenance demands further solidify its place as a cost-effective, long-term investment. In terms of SEO optimization, ensuring content authenticity and reliable sources is integral to establishing the credibility of OEM fly wire netting information online. Engaging articles backed by genuine data and client testimonials can expand the digital footprint of companies offering these solutions, connecting them with a broader, global market. By articulating the tangible benefits of this netting through search-optimized content, firms can enhance their online visibility and consumer trust. In conclusion, OEM fly wire netting is not just an ancillary product but a pivotal one that has reshaped the landscape of pest control. Its efficacy, backed by empirical evidence and user testimonials, affirms its status as a leader in providing comprehensive solutions across various sectors. Integrating state-of-the-art engineering with consumer needs, it embodies innovation that inspires trust and showcases a commitment to improving quality of life and operational efficiency worldwide.

For industrial use, OEM fly wire netting offers resilience and customization options for large-scale facilities requiring specific dimensions and material characteristics. It efficiently addresses environmental challenges, including dust and debris management in warehouses and manufacturing sites, demonstrating its integral role in maintaining sanitized, operational spaces. The installation process of this netting is straightforward, reflecting a user-centered design philosophy that prioritizes ease of use and accessibility. Professionals and DIY enthusiasts alike appreciate the simplistic, guided installation process, reducing labor costs and minimizing downtime. Its low maintenance demands further solidify its place as a cost-effective, long-term investment. In terms of SEO optimization, ensuring content authenticity and reliable sources is integral to establishing the credibility of OEM fly wire netting information online. Engaging articles backed by genuine data and client testimonials can expand the digital footprint of companies offering these solutions, connecting them with a broader, global market. By articulating the tangible benefits of this netting through search-optimized content, firms can enhance their online visibility and consumer trust. In conclusion, OEM fly wire netting is not just an ancillary product but a pivotal one that has reshaped the landscape of pest control. Its efficacy, backed by empirical evidence and user testimonials, affirms its status as a leader in providing comprehensive solutions across various sectors. Integrating state-of-the-art engineering with consumer needs, it embodies innovation that inspires trust and showcases a commitment to improving quality of life and operational efficiency worldwide.

Latest news

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025