ធ្នូ . 20, 2024 20:49 Back to list

hot-dipped galvanized iron wire suppliers

Hot-Dipped Galvanized Iron Wire Suppliers Key Insights and Considerations

Hot-dipped galvanized iron wire is widely recognized for its superior corrosion resistance, strength, and longevity, making it a popular choice across various industries, including construction, agriculture, and manufacturing. This article explores the benefits of hot-dipped galvanized iron wire, the importance of sourcing from reputable suppliers, and key considerations when selecting your supplier.

Understanding Hot-Dipped Galvanized Iron Wire

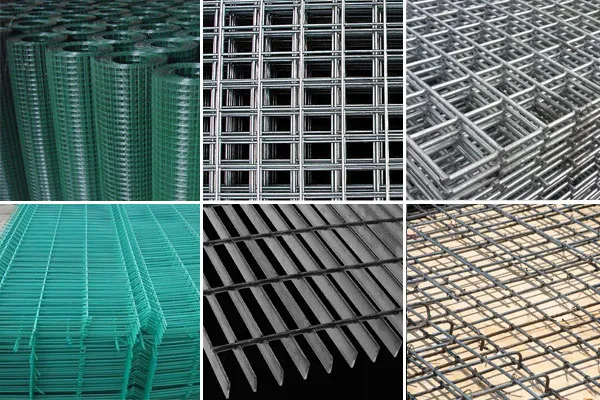

Hot-dipped galvanization is a process that involves coating iron or steel with a layer of zinc. During this process, the metal is submerged into molten zinc, allowing the zinc to react with the iron, forming a metallurgical bond. This results in a robust protective coating that prevents rust and degradation in harsh environments. Hot-dipped galvanized iron wire is utilized for numerous applications, such as fencing, electrical wiring, craft projects, and as reinforcement in concrete.

Benefits of Hot-Dipped Galvanized Iron Wire

1. Corrosion Resistance One of the primary advantages of hot-dipped galvanized iron wire is its exceptional resistance to corrosion. The zinc coating acts as a sacrificial barrier, protecting the underlying metal from moisture, oxygen, and environmental elements. This makes it ideal for outdoor applications or in settings with high humidity.

2. Durability Hot-dipped galvanized iron wire boasts extended service life due to its strong protective layer. This durability reduces the need for frequent replacements or repairs, ultimately leading to cost savings over time.

3. Versatility This type of wire can be used in a wide range of applications, from agricultural fencing to industrial construction. Its adaptability makes it an essential material for many sectors.

4. Eco-Friendliness Zinc is a natural element and can be recycled indefinitely without losing its properties. Using hot-dipped galvanized wire contributes to sustainability efforts in various projects.

hot-dipped galvanized iron wire suppliers

Selecting a Reliable Supplier

When sourcing hot-dipped galvanized iron wire, choosing the right supplier is pivotal to ensure quality and reliability. Here are some key considerations

1. Reputation and Experience Look for suppliers with a proven track record in the industry. Established suppliers are more likely to adhere to quality standards and provide consistent products. Reading reviews and seeking recommendations can be beneficial in this regard.

2. Quality Standards Inquire about the quality certifications the supplier holds. Compliance with international standards, such as ISO certifications, can provide assurance of the product's quality and manufacturing processes.

3. Diversity of Product Offerings A reliable supplier should offer a variety of wire sizes, coatings, and formats to meet various application needs. This flexibility can be crucial for businesses that require tailored solutions.

4. Pricing and Terms While price shouldn't be the only factor, it's essential to compare quotes from different suppliers. Be cautious of prices that seem unusually low, as they may indicate inferior quality. Additionally, review the payment terms and delivery schedules to avoid hindrances in your projects.

5. Customer Support Good customer service is an indicator of a supplier's reliability. Ensure that the supplier has a responsive support team that can address queries, provide technical assistance, and resolve issues efficiently.

Conclusion

Sourcing hot-dipped galvanized iron wire from reputable suppliers is critical for ensuring that your projects benefit from high-quality materials. By understanding the advantages of this type of wire and conducting thorough research when selecting a supplier, businesses can enhance their operational efficiencies and achieve long-term success. With its durability, versatility, and resistance to corrosion, hot-dipped galvanized iron wire remains an indispensable component in a myriad of applications across various industries.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025