ធ្នូ . 20, 2024 20:49 Back to list

oem good quality reinforcing mesh

The Importance of OEM Good Quality Reinforcing Mesh in Construction

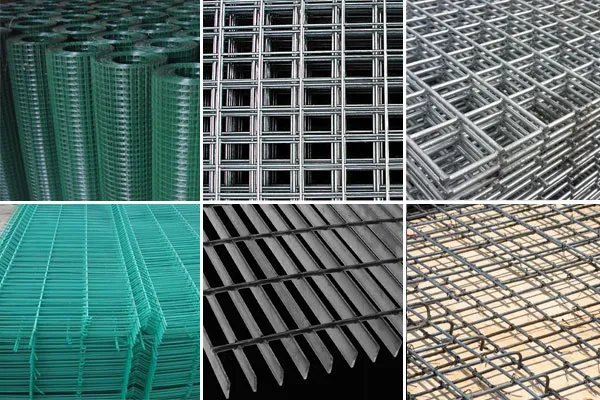

In the ever-evolving world of construction, the pursuit of quality materials is paramount. One such material that has gained significant recognition is reinforcing mesh, especially when produced under OEM (Original Equipment Manufacturer) standards. Reinforcing mesh plays a critical role in enhancing the structural integrity of concrete, which is a key component in various construction projects, from residential buildings to sprawling industrial facilities. This article explores the importance of OEM good quality reinforcing mesh, its applications, and the benefits it offers to the construction industry.

Understanding Reinforcing Mesh

Reinforcing mesh, often referred to as rebar mesh or welded wire mesh, consists of a series of steel wire strands that are welded together to form a grid-like pattern. This mesh is incorporated into concrete to provide additional strength and support, reducing the risk of cracking and failure. The mesh works by distributing loads evenly across the concrete slab, which is essential in applications where heavy loads are anticipated, such as in floor slabs, walls, and pavements.

The Role of OEM Standards

OEM standards are crucial in ensuring the quality and reliability of construction materials. When manufacturers adhere to OEM standards, they commit to producing products that meet specific safety and performance criteria. This is particularly important in the case of reinforcing mesh, where the consequences of using substandard materials can be severe, leading to structural failures, costly repairs, and even endangering lives.

Benefits of Good Quality Reinforcing Mesh

1. Enhanced Structural Integrity OEM good quality reinforcing mesh is designed to withstand various stresses and strains imposed on concrete structures. It helps prevent cracks and increases the longevity of the concrete, ensuring that the structure remains sound for years to come.

2. Improved Load Distribution The grid pattern of the reinforcing mesh facilitates even load distribution across the concrete slab. This is essential in applications like highways and parking garages, where heavy vehicles create significant stress on the surfaces.

oem good quality reinforcing mesh

3. Reduced Risk of Cracking One of the primary purposes of using reinforcing mesh is to minimize the risk of cracking. Good quality mesh ensures that the concrete can expand and contract without suffering significant damage, maintaining the aesthetic and functional value of the structure.

4. Cost-Effectiveness Investing in OEM good quality reinforcing mesh can lead to long-term savings. While the initial cost may be higher than inferior products, the durability and reduced need for repairs can significantly lower maintenance costs over time.

5. Compliance with Regulations Construction projects often must adhere to specific building codes and regulations. Using OEM standards helps ensure that the reinforcing mesh meets these requirements, thus avoiding legal issues and potential fines.

6. Versatility Reinforcing mesh can be tailored to meet the specific needs of a project. OEM manufacturers can produce various sizes, shapes, and materials, ensuring that the mesh fits the project's requirements precisely.

Applications in Construction

The applications of good quality reinforcing mesh are extensive. It is commonly used in

- Residential and Commercial Buildings For foundations, slabs, and walls to ensure stability and durability. - Pavements and Driveways To handle the weight of vehicles and reduce cracking from freeze-thaw cycles. - Bridges and Overpasses Where increased tensile strength is crucial for safety and performance. - Industrial Floors To withstand heavy machinery and high traffic without deteriorating.

Conclusion

The significance of OEM good quality reinforcing mesh in the construction industry cannot be overstated. As construction projects grow in complexity and scale, the demand for reliable materials like reinforcing mesh is ever-increasing. By prioritizing quality and adhering to OEM standards, builders can ensure the safety, longevity, and performance of their structures. In a field where the stakes are high, investing in top-quality reinforcing mesh is not just a matter of compliance; it’s a crucial step toward sustainable and reliable construction practices. As the industry continues to innovate, reinforcing mesh will undoubtedly remain a cornerstone of safe and effective construction.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025