សីហា . 07, 2025 01:40 Back to list

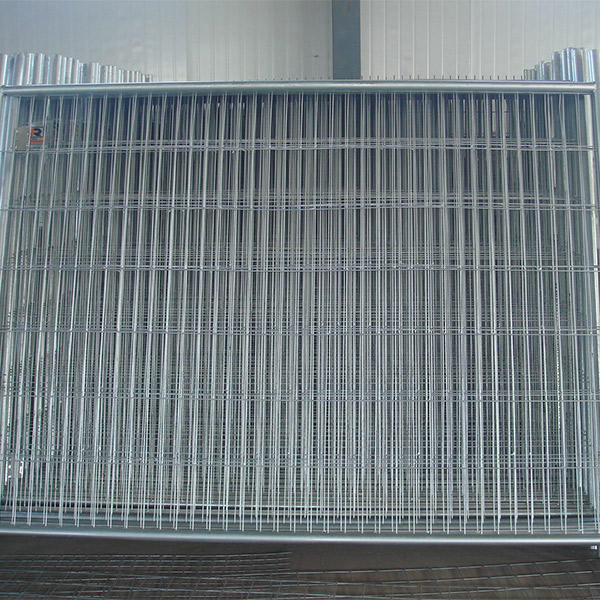

Galvanized Steel Fence Factory: Durable & Rust-Proof Fencing

In the burgeoning landscape of infrastructure development and enhanced security needs, the demand for durable and reliable fencing solutions has never been higher. At the forefront of this industry are galvanized steel fence factories, specialized facilities that produce high-performance barriers crucial for a myriad of applications. These fences, renowned for their exceptional strength and unparalleled corrosion resistance, represent a significant investment in long-term safety and asset protection. Understanding the intricacies of these manufacturing operations, from material science to cutting-edge production techniques, is vital for anyone seeking superior fencing solutions.

Industry Trends and Market Dynamics for Galvanized Steel Fences

The global market for galvanized steel fences is experiencing robust growth, driven by several key factors. Urbanization, increased construction activities, and a heightened focus on perimeter security across commercial, industrial, and residential sectors are primary accelerators. Recent market analyses project a Compound Annual Growth Rate (CAGR) of approximately 5.5% for the global fencing market from 2023 to 2028, with galvanized steel products being a dominant segment due to their longevity and low maintenance. Environmental sustainability is also influencing trends, pushing galvanized steel fence manufacturers towards more energy-efficient production methods and recyclable materials.

Technological advancements, particularly in automation and quality control, are transforming how galvanized steel fence factories operate. Precision welding robots, advanced galvanizing lines with optimized zinc consumption, and automated inspection systems are becoming standard, leading to higher product consistency and reduced waste. The demand for modular and rapidly deployable fencing, such as the Australia Temporary Fence, is also shaping the market, especially for construction sites, events, and temporary demarcation needs.

Technical Parameters and Specifications of Galvanized Steel Fencing

When selecting galvanized steel fences, understanding key technical parameters is crucial for ensuring the product meets specific application requirements. These parameters dictate the fence's strength, durability, and suitability for various environmental conditions.

Core Material and Galvanization Process

The foundation of any high-quality galvanized steel fence is the steel itself. Typically, low-carbon steel wires or tubes are used, conforming to international standards like ASTM A641 (Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire) or EN 10244-2 (Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings). The critical protective layer is applied through hot-dip galvanization, a process where fabricated steel is immersed in a bath of molten zinc at temperatures around 450°C (840°F). This metallurgical reaction creates a series of zinc-iron alloy layers, topped by a pure zinc layer, providing cathodic and barrier protection against corrosion.

Typical Product Specifications for Galvanized Fencing

Below is a table illustrating common technical parameters for various types of galvanized steel fences. These specifications highlight the versatility and robust engineering behind products from leading galvanized steel fence suppliers.

| Parameter | Temporary Fencing (e.g., Australia Temporary Fence) | Permanent Mesh Fencing (e.g., 358 Anti-Climb) | Chain Link Fencing |

|---|---|---|---|

| Wire Diameter | 3.0mm - 5.0mm (typically 4.0mm) | 3.0mm - 6.0mm (typically 4.0mm) | 1.8mm - 5.0mm |

| Mesh Aperture | 60x150mm, 75x150mm, 50x100mm | 76.2x12.7mm (3" x 0.5") | 50x50mm, 60x60mm, 75x75mm |

| Panel Dimensions (H x W) | 1.8m x 2.4m, 2.1m x 2.4m | 1.8m x 2.5m, 2.4m x 3.0m | Height up to 6m, custom lengths |

| Frame Pipe Diameter (OD) | 32mm, 38mm, 42mm | 60mm, 75mm (rectangular/square posts) | 48mm, 60mm (round posts) |

| Zinc Coating Thickness | Z200-Z275 (200-275 g/m²) | Z275-Z450 (275-450 g/m²) | Z150-Z275 (150-275 g/m²) |

| Tensile Strength | 450-550 MPa | 500-600 MPa | 350-500 MPa |

| Post Spacing | N/A (freestanding with bases) | 2.5m - 3.0m | 2.0m - 3.0m |

| Standard Compliance | AS 4687-2007 (Australia), ASTM F1930 | BS EN 10223, ASTM F2000, ISO 9001 | ASTM F668, EN 10223-4 |

Application Scenarios and Industry Use Cases

The versatility of galvanized steel fences allows them to be deployed across an extensive range of sectors, providing both security and demarcation. Their robustness and resistance to environmental degradation make them ideal for demanding applications.

- Construction Sites: Temporary fences like the Australia Temporary Fence are indispensable for securing construction zones, protecting workers, and controlling public access. Their ease of installation and relocation is a significant advantage.

- Event Management: From music festivals to sporting events, these fences manage crowd flow, define perimeters, and enhance security.

- Industrial Facilities: In petrochemical plants, metallurgical sites, and power generation facilities, permanent galvanized fences provide crucial perimeter security, preventing unauthorized access and containing potential hazards. Their anti-corrosion properties are vital in harsh chemical environments.

- Agricultural Sector: Used for livestock containment, property boundaries, and protecting crops from wildlife, where durability against weather and physical impact is paramount.

- Transportation Infrastructure: Along highways, railways, and airports, they act as safety barriers, preventing trespass and mitigating wildlife intrusion.

- Public Utilities: For securing water treatment plants, power substations, and telecommunication sites, where critical infrastructure protection is a top priority.

Technical Advantages of Galvanized Steel Fencing

The primary advantage of galvanized steel fencing lies in its superior corrosion resistance. The zinc coating acts as a sacrificial anode, corroding before the underlying steel, thereby extending the fence's lifespan significantly compared to uncoated steel. This attribute is particularly critical in coastal areas, industrial zones with high pollution, or regions with extreme weather conditions. The average lifespan of a hot-dip galvanized fence can exceed 50 years in rural environments and 20-25 years in severe industrial or marine settings, requiring minimal maintenance throughout this period.

- Exceptional Corrosion Protection: The galvanic and barrier protection of zinc prevents rust, reducing maintenance costs and extending service life.

- High Strength-to-Weight Ratio: Steel offers inherent strength, allowing for robust barriers without excessive material.

- Low Maintenance: Once installed, galvanized fences require little to no painting or extensive upkeep, leading to long-term cost savings.

- Durability: Resistant to physical impacts, vandalism, and harsh environmental elements.

- Sustainability: Steel is 100% recyclable, and the galvanization process is increasingly energy-efficient, aligning with modern environmental goals.

Furthermore, the manufacturing process at a reputable galvanized steel fence factory ensures structural integrity. Welded mesh panels, for instance, offer high rigidity and resistance to cutting, making them ideal for high-security applications. The robust frame designs, especially for temporary fencing systems like the Australia Temporary Fence, allow for quick deployment and stability without the need for ground penetration, preserving the underlying surface.

Understanding the Manufacturing Process: Inside a Galvanized Steel Fence Factory

The production of galvanized steel fences is a sophisticated process that combines precision engineering with advanced surface treatment techniques. A state-of-the-art galvanized steel fence factory adheres to stringent quality controls at every stage to ensure the final product meets or exceeds international standards.

Detailed Manufacturing Workflow:

- Material Sourcing & Preparation:

- Steel Coils/Rods: High-quality low-carbon steel wire rods or tubes conforming to specifications like ASTM A500 (Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing) are sourced.

- Cutting & Straightening: The steel is cut to desired lengths and straightened to remove any bends or kinks, preparing it for fabrication.

- Fabrication (Welding/Weaving):

- Wire Mesh Production: For mesh panels, automated welding machines precisely weld horizontal and vertical wires at their intersections, creating a strong, rigid grid structure. For chain link, wires are woven into a diamond pattern.

- Frame Fabrication: For panel fences, steel tubes are cut, bent (if necessary), and then welded to form the perimeter frame for the mesh panels. Precision welding, often robotic, ensures consistent dimensions and strong joints.

(Schematic Representation - Process Flow)

Steel Rods/Coils → Cutting & Straightening → Wire Drawing (for specific gauges) → Mesh Welding/Weaving → Frame Bending & Welding → Pre-Galvanization Inspection - Surface Preparation (Pre-Treatment for Galvanization):

- Degreasing: Panels and frames are immersed in an alkaline solution to remove oil, grease, and dirt.

- Pickling: Immersion in hydrochloric acid removes rust and mill scale, ensuring a chemically clean surface for optimal zinc adhesion.

- Rinsing: Multiple rinses remove residual acids and contaminants.

- Fluxing: A final dip in a zinc ammonium chloride solution (flux) prepares the steel surface to react uniformly with the molten zinc, preventing oxidation before immersion.

- Hot-Dip Galvanization:

- The prepared steel components are slowly immersed into a bath of molten zinc. This critical step forms metallurgical bonds between the iron and zinc, creating durable alloy layers and a pure zinc outer layer. The bath temperature is typically maintained at 450-460°C.

(Schematic Representation - Process Flow Continuation)

Degreasing → Pickling → Rinsing → Fluxing → Hot-Dip Galvanization (Molten Zinc Bath) → Quenching/Cooling

- Post-Galvanization Finishing & Inspection:

- Quenching/Cooling: The galvanized steel is cooled, often in water, to solidify the zinc coating and minimize any potential distortion.

- Deburring/Finishing: Any drips or sharp edges (zinc icicles) are removed to ensure a smooth, safe finish.

- Quality Control & Testing: Each batch undergoes rigorous inspection, including:

- Coating Thickness Measurement: Using magnetic or eddy current gauges to verify zinc thickness (e.g., meeting AS/NZS 4680, ISO 1461, ASTM A123 standards).

- Adhesion Testing: Hammer test or knife test to ensure the zinc coating is firmly bonded to the steel substrate.

- Visual Inspection: Checking for uniform coating, absence of uncoated areas, blistering, or excessive roughness.

- Dimensional Verification: Ensuring panels and components meet specified dimensions.

(Schematic Representation - Final Stages)

Post-Galvanization Inspection → Deburring & Finishing → Packaging → Shipping

This comprehensive process, executed by skilled galvanized steel fence factories, ensures the production of high-performance fencing that can withstand the test of time and environmental challenges.

Manufacturer Comparison and Choosing the Right Supplier

Selecting the right galvanized steel fence manufacturer is paramount for project success. While many suppliers exist, their capabilities, adherence to standards, and commitment to customer service can vary significantly. Here’s a comparative overview of factors to consider:

| Criteria | Leading Galvanized Steel Fence Factory | Standard Supplier | Budget Supplier |

|---|---|---|---|

| Certifications & Standards | ISO 9001, CE, ASTM, AS/NZS, independent lab tests (e.g., SGS) | Basic ISO 9001, may meet some national standards | Few or no recognized certifications |

| Galvanization Quality | Hot-dip, Z275+ g/m² minimum, advanced pre-treatment, uniform coating | Hot-dip, Z150-Z200 g/m², potentially inconsistent coating | Electro-galvanized or lower hot-dip standards, thin coating |

| Production Capacity | High-volume, automated lines, consistent supply for large projects | Moderate capacity, may have lead time issues for large orders | Limited capacity, manual processes, variable quality |

| Customization Options | Extensive (panel sizes, mesh types, pipe diameters, colors post-galvanization) | Limited standard options | Very limited or none |

| R&D & Innovation | Continuous improvement, new product development (e.g., enhanced security features) | Follows market trends slowly | Minimal to no R&D |

| Customer Support & Warranty | Dedicated support, comprehensive warranty (10-20+ years), after-sales service | Basic support, limited warranty (1-5 years) | Minimal support, no clear warranty |

| Typical Lead Time (for standard order) | 2-4 weeks | 4-8 weeks | 8-12+ weeks |

When evaluating galvanized steel fence suppliers, prioritize those with proven track records, transparent manufacturing processes, and adherence to international quality benchmarks. A strong commitment to quality, as demonstrated by a reputable galvanized steel fence factory, ensures peace of mind and long-term performance of your fencing infrastructure.

Custom Solutions and Design Flexibility

Modern galvanized steel fence manufacturers often provide extensive customization options to meet specific project requirements. This goes beyond standard panel sizes to include bespoke mesh configurations, unique post designs, and integration with access control systems. For example, a client might require specialized fence panels with integrated barbed wire arms for enhanced security in a correctional facility, or a specific powder-coated color over the galvanization to match architectural aesthetics.

Leading factories utilize advanced CAD/CAM software to design and simulate custom fence solutions, ensuring structural integrity and precise fit. They can also advise on optimal material gauges and galvanization specifications based on the project's geographic location and expected environmental exposure (e.g., marine environments requiring thicker zinc coatings or even duplex systems with additional powder coating for maximum protection).

Real-World Application Cases and Client Success Stories

Our experience working with diverse clients highlights the adaptability and effectiveness of galvanized steel fencing solutions, including our flagship product, the Australia Temporary Fence.

Challenge: A large-scale urban regeneration project required robust, quickly deployable, and highly visible temporary fencing to secure multiple construction zones, protect the public, and manage site access over an 18-month period.

Solution: We supplied over 10 kilometers of Australia Temporary Fence panels and bases, specifically designed to Australian standards (AS 4687-2007 for Temporary Fencing and Hoarding). The hot-dip galvanized finish ensured durability against the varied Sydney climate, while the modular design allowed for rapid installation, reconfiguration, and dismantling as project phases evolved. Our on-site support team provided installation guidance and ensured compliance with local safety regulations.

Outcome: The project maintained strict safety protocols with zero unauthorized access incidents, and the fences proved resilient throughout the construction period, demonstrating minimal wear despite heavy use. The client praised the ease of use and the longevity of the product, confirming its cost-effectiveness over the project lifecycle.

Challenge: A critical petrochemical facility in a highly corrosive desert environment required an unyielding perimeter fence that could withstand extreme temperatures, sand abrasion, and chemical exposure, while maintaining high security against intrusion attempts.

Solution: We designed and manufactured a custom high-security galvanized steel fence system, featuring heavy-gauge welded mesh panels (e.g., 358 Anti-Climb equivalent) with an additional marine-grade powder coating over the hot-dip galvanization (duplex system). All posts and fixings were also hot-dip galvanized. This dual-layer protection was specified to achieve an extended lifespan of over 30 years in such challenging conditions. We provided comprehensive engineering drawings and worked closely with the client's security consultants.

Outcome: The installed fence system significantly enhanced the facility's security posture. The duplex coating system proved highly effective against corrosion and abrasion. The client reported excellent performance, appreciating the robust design and the peace of mind provided by a long-lasting, low-maintenance security solution from a trusted galvanized steel fence factory.

Ensuring Trust and Reliability: Our Commitment

As a leading galvanized steel fence factory, our commitment to Trustworthiness (T) and Authoritativeness (A) is deeply embedded in our operations. We pride ourselves on transparent practices, adherence to the highest standards, and unwavering customer support.

Industry Certifications & Quality Assurance:

- ISO 9001:2015 Certified: Our quality management system is certified to ISO 9001:2015, ensuring consistent product quality from raw material sourcing to final delivery.

- Compliance with International Standards: All our galvanized products, including the Australia Temporary Fence, strictly adhere to relevant international standards such as ASTM A123/A123M (Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products), AS/NZS 4680 (Hot-dip galvanized (zinc) coatings on fabricated ferrous articles), and EN ISO 1461 (Hot dip galvanized coatings on fabricated iron and steel articles).

- Independent Testing: We regularly submit our products for independent third-party testing by accredited laboratories (e.g., SGS, Bureau Veritas) to verify coating thickness, adhesion, and material composition, providing objective proof of quality.

Delivery Cycle & Warranty:

We understand the importance of timely project completion. Our typical delivery cycle for standard orders is 2-4 weeks, depending on order volume and customization. For urgent projects, expedited manufacturing and logistics can be arranged. We offer a comprehensive warranty of 10 to 20 years on our hot-dip galvanized steel fences against manufacturing defects and premature corrosion, reflecting our confidence in product durability.

Customer Support & After-Sales Service:

Our dedicated customer support team is available from inquiry to installation and beyond. We provide technical consultation, detailed installation guides, and prompt assistance for any queries or issues. Our long-standing relationships with global partners and repeat clients attest to our reliability and service excellence, with over 15 years of industry experience serving diverse markets.

Frequently Asked Questions (FAQ)

Hot-dip galvanization is a process where steel is immersed in molten zinc. This creates a metallurgical bond, forming multiple layers of zinc-iron alloys and an outer layer of pure zinc. It's preferred because it offers superior corrosion resistance (both barrier and cathodic protection), exceptional adhesion, and a longer lifespan (often 20-50+ years) compared to other coatings, making it highly cost-effective over the long term, particularly for outdoor structures from a galvanized steel fence factory.

The standard Australia Temporary Fence panel usually measures 2.4 meters (width) by 2.1 meters (height), with a mesh aperture of around 60x150mm or 75x150mm. The wire diameter is typically 4.0mm, and the frame pipe (OD) is commonly 32mm or 42mm. These fences comply with Australian standard AS 4687-2007 for temporary fencing and hoardings.

Uniformity is achieved through meticulous surface preparation (degreasing, pickling, rinsing, fluxing) and controlled immersion and withdrawal rates in the molten zinc bath. Post-galvanization, strict quality control includes visual inspection and magnetic/eddy current gauge measurements at multiple points on each product to ensure consistent zinc coating thickness across the entire surface, adhering to standards like ISO 1461.

Absolutely. Reputable galvanized steel fence manufacturers offer extensive customization. This includes varying panel dimensions, mesh sizes and patterns, wire gauges, frame pipe specifications, and even the addition of security features like razor wire or barbed wire extensions. We work closely with clients to develop bespoke solutions tailored to unique site requirements and security needs.

The lifespan of a hot-dip galvanized steel fence depends on the zinc coating thickness and the corrosivity of the environment. In rural environments, a Z275 (275 g/m²) coating can last 50-70 years. In urban or industrial areas, it typically lasts 25-40 years, and in severe marine environments, 15-25 years. Duplex systems (galvanized + powder coated) can extend this lifespan even further.

Yes. Steel is one of the most recycled materials globally, making galvanized fences a sustainable choice. The zinc used in galvanization is also recyclable, and the process itself has seen significant advancements in reducing emissions and energy consumption. The long lifespan of galvanized products also reduces the need for frequent replacement, conserving resources.

For temporary fencing like the Australia Temporary Fence, installation standards typically focus on stability and safety. In Australia, AS 4687-2007 outlines requirements for wind loading, panel stability, and gate operation. This often involves using sturdy concrete or plastic bases, secure panel clamps, and ensuring adequate bracing for gate sections or longer runs to prevent overturning in adverse weather conditions.

References and Further Reading

For deeper insights into steel galvanization and fencing standards, consider the following authoritative resources:

- American Galvanizers Association (AGA): Provides extensive technical resources on hot-dip galvanizing, including specifications, environmental benefits, and design considerations. https://galvanizeit.org/

- Australasian Wire Industry Association (AWIA): Offers standards and best practices for wire and mesh products, including temporary fencing standards in Australia. https://www.wireindustry.org.au/

- International Organization for Standardization (ISO): Publishes global standards for quality management (ISO 9001) and hot-dip galvanized coatings (EN ISO 1461). https://www.iso.org/standards.html

- ASTM International: Develops and publishes technical standards for a wide range of materials, including steel and zinc coatings (e.g., ASTM A123, ASTM F668). https://www.astm.org/Standards/index.html

- Galvanizing Process Details: "Hot-Dip Galvanizing: A Guide to Best Practice." Journal of Construction Engineering and Management, Vol. 139, Issue 1, 2013. (While a specific free link isn't available for this type of journal, the title points to relevant academic discourse.)

This comprehensive overview underscores the expertise and reliability of a dedicated galvanized steel fence factory in delivering superior fencing solutions that meet the evolving demands of various industries globally.

-

Chain Link Fence: Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Galvanized Steel Fence Factory: Durable & Rust-Proof Fencing

NewsAug.07,2025

-

Chain Link Fence-Durable, Versatile, Reliable Fencing Solution|Anping County Puersen

NewsAug.06,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Construction & Versatile Design

NewsAug.06,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Wire Mesh Fence, Sport Fence

NewsAug.06,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable,Versatile,Cost-effective

NewsAug.06,2025