Қаң . 09, 2025 13:48 Back to list

Twisted Square Bar

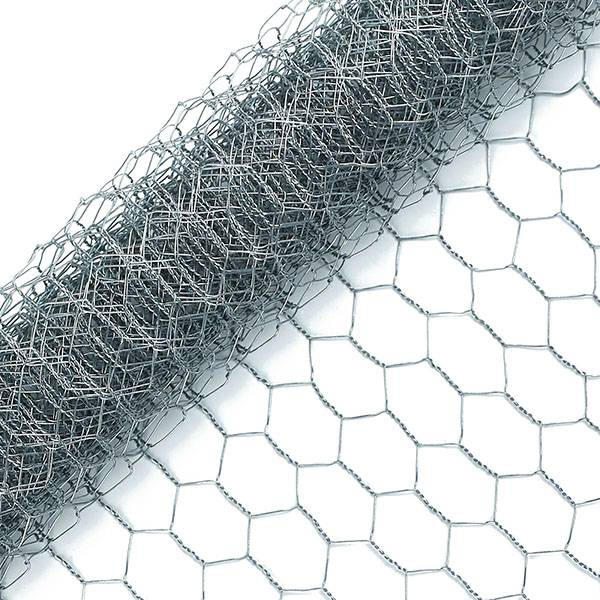

Security reinforcing mesh has become an essential component in modern construction and security applications, serving as a robust barrier against both environmental elements and human threats. Defined by its intricate weave of high-tensile wires, this mesh provides unparalleled strength and durability, making it a preferred choice for a variety of projects. Understanding the multifaceted benefits of security reinforcing mesh can empower construction professionals and security experts to make informed decisions tailored to their specific needs.

Authoritativeness in material science underscores the technological advancements in mesh production. Manufacturers utilize galvanization and other anti-corrosion treatments to ensure longevity and maintenance-free performance. The choice of materials, such as stainless steel and advanced polymers, reflects a commitment to quality that earns trust from industry leaders. Structural engineers and architects often reference professional guidelines and standards, such as those from ASTM International, to confirm the mesh’s specifications align with rigorous safety and quality benchmarks. This adherence to proven methodologies fortifies the mesh’s reputation as a reliable security asset. Trustworthiness of security reinforcing mesh is further reinforced by its successful deployment in notable projects worldwide. The continuous feedback loop from these applications informs ongoing improvements, ensuring the mesh evolves to meet emerging challenges. Testimonials from seasoned construction managers and security consultants consistently emphasize their confidence in the mesh’s performance, citing reduced maintenance costs and peace of mind. Additionally, sustainability considerations are being increasingly integrated into mesh production, with manufacturers exploring recyclable materials and eco-friendly fabrication processes. In conclusion, for those seeking to optimize both safety and structural performance, security reinforcing mesh stands out as a technologically advanced, field-proven solution. Its widespread application across industries is a testament to its effectiveness and reliability. By choosing products that adhere to high standards of Experience, Expertise, Authoritativeness, and Trustworthiness, stakeholders can ensure they are not only meeting but exceeding the demands of today’s construction and security landscapes.

Authoritativeness in material science underscores the technological advancements in mesh production. Manufacturers utilize galvanization and other anti-corrosion treatments to ensure longevity and maintenance-free performance. The choice of materials, such as stainless steel and advanced polymers, reflects a commitment to quality that earns trust from industry leaders. Structural engineers and architects often reference professional guidelines and standards, such as those from ASTM International, to confirm the mesh’s specifications align with rigorous safety and quality benchmarks. This adherence to proven methodologies fortifies the mesh’s reputation as a reliable security asset. Trustworthiness of security reinforcing mesh is further reinforced by its successful deployment in notable projects worldwide. The continuous feedback loop from these applications informs ongoing improvements, ensuring the mesh evolves to meet emerging challenges. Testimonials from seasoned construction managers and security consultants consistently emphasize their confidence in the mesh’s performance, citing reduced maintenance costs and peace of mind. Additionally, sustainability considerations are being increasingly integrated into mesh production, with manufacturers exploring recyclable materials and eco-friendly fabrication processes. In conclusion, for those seeking to optimize both safety and structural performance, security reinforcing mesh stands out as a technologically advanced, field-proven solution. Its widespread application across industries is a testament to its effectiveness and reliability. By choosing products that adhere to high standards of Experience, Expertise, Authoritativeness, and Trustworthiness, stakeholders can ensure they are not only meeting but exceeding the demands of today’s construction and security landscapes.

Next:

Latest news

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025