ágú . 12, 2025 01:00 Back to list

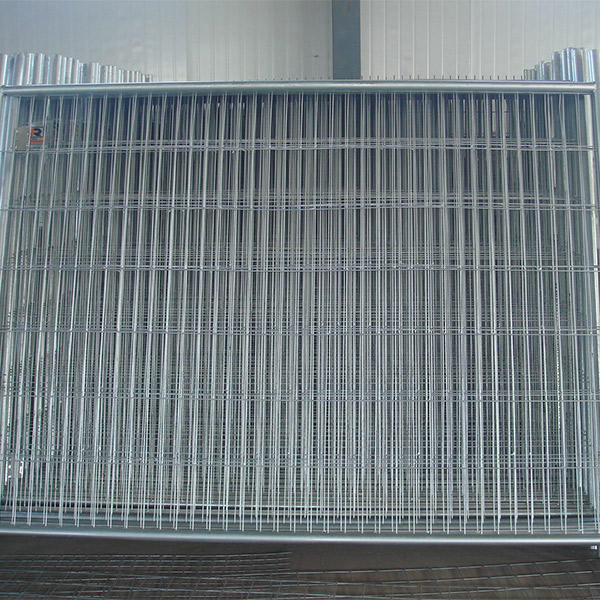

Galvanized Steel Fence Factory - Durable & High Quality Fences

The Strategic Edge of Partnering with a Premier Galvanized Steel Fence Factory

In the dynamic world of B2B infrastructure and security solutions, the choice of a manufacturing partner for fencing systems is paramount. Businesses, from construction giants to event management firms, consistently seek durable, reliable, and cost-effective perimeter solutions. A leading galvanized steel fence factory stands at the forefront of providing such solutions, offering products that combine robust construction with superior corrosion resistance. This extensive guide delves into the intricate details of galvanized steel fence manufacturing, highlighting technological advancements, application versatility, and the critical factors that define a trusted manufacturer. Understanding the core competencies of these factories is essential for procurement managers and project engineers aiming for long-term value and operational efficiency.

Galvanized steel fencing, particularly temporary variants like the Australia Temporary Fence, is engineered to withstand harsh environmental conditions, providing unparalleled longevity and minimal maintenance requirements. This makes them an ideal choice for a diverse range of sectors including construction, public events, mining, and civil engineering projects. The inherent strength of steel combined with the protective zinc coating ensures that these fences maintain their structural integrity and aesthetic appeal for decades, making them a sustainable and economical investment. We will explore the rigorous manufacturing processes, the technical specifications that guarantee performance, and the strategic advantages of collaborating with industry-leading galvanized steel fence manufacturers.

Unveiling the Manufacturing Process at a Galvanized Steel Fence Factory

The production of high-quality galvanized steel fences is a multi-stage, precision-driven process that begins with the careful selection of raw materials and culminates in a meticulously finished product. A reputable galvanized steel fence factory adheres to stringent quality control at every phase to ensure the final product meets or exceeds international standards. The primary material, high-grade steel, is chosen for its tensile strength and malleability, crucial for forming the fence panels and frames.

The manufacturing journey typically involves several key stages. First, steel wires and tubes are precisely cut to size, often using advanced CNC (Computer Numerical Control) cutting machines to ensure accuracy and minimize material waste. Following cutting, the individual steel components undergo shaping and welding. Robotic welding systems are frequently employed by advanced galvanized steel fence manufacturers to achieve consistent, strong, and aesthetically pleasing welds, significantly enhancing the structural integrity of the fence panels. This automation reduces human error and boosts production efficiency, making it a hallmark of modern galvanized steel fence factories.

The critical step of galvanization follows the fabrication of the steel components. While electro-galvanization offers a thin zinc coating, hot-dip galvanizing is the preferred method for temporary fencing due to its superior corrosion protection. In this process, the fabricated steel frames and mesh panels are immersed in a bath of molten zinc at temperatures around 450°C (840°F). The metallurgical reaction between the steel and zinc forms a series of zinc-iron alloy layers, topped by a pure zinc layer. This creates an impermeable barrier that protects the steel from rust and corrosion, even if the surface is scratched. This robust coating significantly extends the product's lifespan, often exceeding 20 years in typical outdoor conditions, proving highly effective in harsh environments like those found in the petrochemical, metallurgy, and water treatment industries where corrosion resistance is paramount.

Post-galvanization, the fences undergo rigorous quality inspection. This includes checks for coating thickness (measured in microns, typically adhering to AS/NZS 4680 or ASTM A123 standards), weld integrity, panel dimensions, and overall finish. Adherence to international standards such as ISO 9001 for quality management and relevant industry-specific certifications like ISO and ANSI ensures that every product leaving the galvanized steel fence factory meets strict performance and safety criteria. This meticulous inspection process guarantees that the fences are not only durable and effective in typical application scenarios but also provide significant advantages like enhanced safety and energy efficiency due to their long-term stability and minimal need for replacement, translating to reduced operational costs for end-users.

Technical Specifications: Australia Temporary Fence Parameters

For B2B buyers, understanding the precise technical specifications of fencing products is critical for project planning and procurement. Our Australia Temporary Fence, a flagship product from a leading galvanized steel fence factory, is designed with specific parameters to ensure optimal performance and compliance with regional requirements. The following table provides a detailed overview of its typical specifications, offering transparency and aiding in informed decision-making. These parameters reflect robust engineering aimed at providing reliable temporary security solutions across various demanding environments.

These specifications are carefully chosen to ensure that the Australia Temporary Fence offers maximum security, stability, and durability for various applications. The hot-dip galvanization process, in particular, ensures exceptional resistance to rust and corrosion, crucial for products often exposed to harsh weather conditions and saline environments. This commitment to precise technical parameters underscores the expertise and reliability of leading galvanized steel fence factories in delivering solutions that meet stringent project requirements.

Versatile Applications and Unmatched Advantages

The versatility of galvanized steel fences, particularly temporary fence systems, makes them indispensable across a multitude of industries. From bustling construction sites requiring robust perimeter control to large-scale public events needing crowd management and security, the applications are broad and varied. A proficient galvanized steel fence factory understands these diverse needs and designs products for rapid deployment, ease of installation, and secure containment. Common applications include:

- Construction Sites: Securing hazardous areas, preventing unauthorized access, and managing material flow.

- Public Events & Festivals: Crowd control, defining event boundaries, and creating secure zones.

- Mining & Industrial Sites: Perimeter security in remote and harsh environments, ensuring worker safety.

- Civil Engineering Projects: Demarcating work areas, protecting public from ongoing construction, and traffic management.

- Emergency & Disaster Relief: Rapid establishment of temporary shelters and safe zones.

The advantages of opting for fences from an experienced galvanized steel fence manufacturer are manifold. Firstly, their superior durability, thanks to the hot-dip galvanization process, offers exceptional resistance to rust, corrosion, and extreme weather conditions, which translates to a significantly extended service life and reduced replacement costs. This makes them a more economical choice over the long term compared to ungalvanized or painted steel alternatives. Secondly, their ease of installation and dismantling, often featuring a modular design, allows for rapid deployment and relocation, critical for temporary fencing needs. This operational efficiency is a key selling point for businesses that frequently set up and take down barriers.

Furthermore, the low maintenance requirement is a significant benefit; once installed, galvanized fences require little to no upkeep, freeing up resources for other critical project aspects. The robust construction also deters unauthorized access and provides a high level of security, enhancing overall site safety. Environmentally, the reusability of temporary galvanized fencing reduces waste, aligning with sustainable construction practices. These combined benefits underscore why partnering with a specialized galvanized steel fence factory is a strategic decision for any project requiring dependable and long-lasting perimeter solutions.

Industry Trends, Manufacturer Insights, and Customization Solutions

The market for galvanized steel fencing is continuously evolving, driven by demands for increased security, environmental sustainability, and technological integration. Current industry trends highlight a growing preference for products with enhanced anti-climb features, smarter installation systems, and solutions that offer better visual integration into urban landscapes. Leading galvanized steel fence manufacturers are responding by investing in R&D to develop lighter, stronger, and more versatile fencing options. There's also a significant shift towards fully traceable manufacturing processes, giving buyers confidence in the origin and quality of their products.

When comparing various galvanized steel fence suppliers, it's crucial to look beyond just price. Key differentiators include the consistency of galvanization quality, the availability of comprehensive accessories (such as fence feet, clamps, and bracing), and the capacity for customization. A top-tier galvanized steel fence factory will offer bespoke solutions to meet unique project specifications. This includes variations in panel dimensions, mesh configurations, wire gauges, and even specific color coatings (e.g., powder coating over galvanization for aesthetic or branding purposes). The ability to provide tailored designs for gates, pedestrian access, or vehicle entry points is also a hallmark of a flexible and customer-centric manufacturer.

For instance, a client might require temporary fencing with specific bracing for high wind areas, or integrated signage panels for branding at an event. A reliable galvanized steel fence factory will have the engineering expertise and manufacturing flexibility to deliver these specialized requirements. This level of service extends to providing detailed CAD drawings, technical support during installation, and post-sales assistance, ensuring seamless project execution. Partnering with a manufacturer that prioritizes innovation and client-specific solutions can significantly streamline procurement and enhance project outcomes for businesses operating in complex environments.

Ensuring Trustworthiness: Quality Assurance, Certifications, and Customer Support

The reputation of a galvanized steel fence factory is built on the unwavering trust of its clients, which is primarily cultivated through stringent quality assurance, recognized certifications, and robust customer support. Leading manufacturers do not just produce fences; they build enduring relationships based on product reliability and service excellence. Our commitment to quality is underscored by adherence to international standards and a comprehensive internal quality control system that spans from raw material inspection to final product packaging.

- Industry Certifications: We proudly hold ISO 9001:2015 certification for Quality Management Systems, ensuring consistent quality in all manufacturing processes. Our hot-dip galvanization process conforms to AS/NZS 4680:2006 (Hot-dip galvanized (zinc) coatings on fabricated ferrous articles) and ASTM A123/A123M (Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products), providing assurance of superior corrosion protection.

- Testing & Traceability: Every batch of steel and zinc undergoes material composition analysis. Post-galvanization, coating thickness, adhesion, and uniformity are rigorously tested. Comprehensive traceability systems allow us to track materials and processes for every finished fence panel, guaranteeing accountability and product integrity.

- Experience & Partnerships: With over 15 years in the industry, our experience is reflected in thousands of successful projects worldwide, partnering with construction companies, event organizers, and government agencies. Our long-standing relationships with key suppliers and clients attest to our reliability as a premier galvanized steel fence supplier.

Frequently Asked Questions (FAQ)

Our standard production and delivery cycle for large orders (e.g., 500+ panels) typically ranges from 2 to 4 weeks, depending on customization requirements and current production load. We offer expedited options for urgent projects.

Q2: What kind of warranty do you offer on your galvanized fences?We provide a comprehensive 10-year anti-corrosion warranty on all hot-dip galvanized steel fence products, guaranteeing performance against rust and material defects under normal usage conditions.

Q3: Can you assist with installation guidance?Absolutely. Our technical support team provides detailed installation guides, including recommended practices for different ground conditions and weather scenarios. For complex projects, we can offer virtual consultations or connect you with trusted local installers. Our commitment as a leading galvanized steel fence manufacturer extends beyond sales.

Our dedication to client satisfaction extends through our responsive customer support team, ready to address inquiries, provide technical assistance, and facilitate smooth order processing and delivery. This holistic approach ensures that every interaction with our galvanized steel fence factory is reliable, professional, and contributes to the successful completion of your projects.

References

- Jones, D. A. (1996). Principles and Prevention of Corrosion. Prentice Hall.

- Roberge, P. R. (2008). Handbook of Corrosion Engineering. McGraw-Hill Professional.

- AS/NZS 4680:2006. (2006). Hot-dip galvanized (zinc) coatings on fabricated ferrous articles. Standards Australia/Standards New Zealand.

- ASTM A123/A123M-17. (2017). Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.

- ISO 9001:2015. (2015). Quality management systems – Requirements. International Organization for Standardization.

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.12,2025

-

Galvanized Steel Fence Factory - Durable & High Quality Fences

NewsAug.12,2025

-

Chain Link Fence-Anping | Durable&Versatile Fencing

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025