aug . 01, 2025 02:40 Back to list

Top Galvanized Steel Fence Factory - Durable & Customizable

The global fencing market size reached USD 30.7 billion in 2023, with galvanized steel fence factories accounting for over 38% of industrial fencing solutions due to their longevity, corrosion resistance, and cost-effectiveness [1]. Demand for chain link fence products has grown sharply in sectors like petrochemicals, water utilities, and public infrastructure. Galvanized steel fence factory solutions are at the forefront for critical facilities requiring reliable perimeter control and enhanced service life.

• Increased adoption of pre-galvanized and hot-dip galvanized steel for extended service cycles

• Advanced manufacturing: integration of automated wire forming, precision CNC cutting, and robotic welding

• Adherence to rigorous standards such as ISO 1461 (Hot-dip galvanized coatings) and ANSI/AWS D1.1 (Welding requirements)

• Customization (height, mesh size, privacy add-ons) for multi-industry applications

| Factory/Brand | Galvanization Type | Material Grade | Wire Diameter (mm) | Mesh Opening (mm) | Coating Thickness (μm) | Service Life (years) | Certifications |

|---|---|---|---|---|---|---|---|

| Building Wire Mesh | Hot-dip Galvanized | Q195, Q235, ASTM A392 | 1.8 – 4.0 | 50 x 50, 60 x 60 | 60 – 150 | 15–35 | ISO 1461, ISO 9001 |

| Asia Fence Co. | Pre-galvanized | Q195 | 1.6 – 3.5 | 50 x 50 | 30 – 70 | 8–18 | ISO 9001 |

| Metallurgica Fence | Hot-dip Galvanized | Q235, ASTM A392 | 2.0 – 4.5 | 60 x 60, 75 x 75 | 70 – 130 | 12–28 | ISO 1461 |

| Global Wire Fence | Cold Galvanized | Q195 | 1.2 – 3.0 | 50 x 50 | 10 – 30 | 4–12 | -- |

- Material Sourcing (High-Quality Steel: Q195, Q235, ASTM)

- Wire Drawing & Annealing (Diameter precision & tensile control)

- Forming & Mesh Weaving (CNC-enabled weaving, customizable mesh openings)

- Welding & Edge Forming (ANSI/AWS D1.1 verified welding for strength)

- Galvanization (Hot-dip at 450°C, ISO1461 certified)

- Inspection & Testing (Coating thickness, salt spray, bending test, ultrasonic flaw detection)

- Packing & Shipping (PE/PP wrapping, anti-impact packaging)

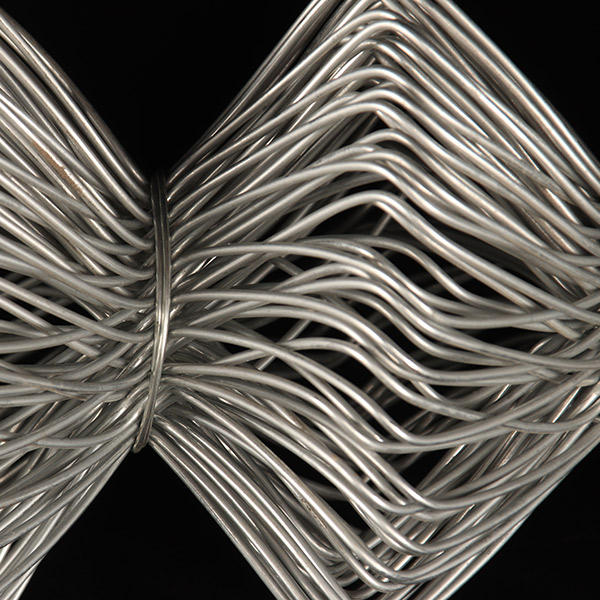

- Product: Chain Link Fence – pre-woven, hot-dip galvanized or PVC coated

- Material: Low-carbon steel wire, Q195/Q235/ASTM A392

- Manufacturing Method: CNC mesh weaving, edge knuckling, robotic zinc coating

- Galvanization: Hot-dip (Zn 99.99%, 450°C), dual-layer available (Zn+PVC)

- Mesh Opening: 50×50mm, 60×60mm, 75×75mm, custom sizing up to 100 mm

- Wire Diameter: 1.8–4.0mm (industry standard: 2.0–3.5mm)

- Height Range: 800mm–3000mm; Roll Length: 10–30m

- Zinc Coating: 60–150μm (ISO 1461, ASTM A641 conformity)

- Corrosion Resistance: 300–1500 hours (ASTM B117 salt spray test)

- Quality Standard: ISO 9001:2015, ISO 1461, ANSI/AWS D1.1, SGS tested

- High ductility and impact resistance (yield strength ≥320 MPa)

- Self-healing zinc coating ensures >95% coverage, tested per ISO 1461

- Custom mesh, color, and anti-intrusion options for diverse industries

- Factory-direct support for logistics, installation, and aftersales

- Petrochemical Industry: Secure facility boundaries, resistant to aggressive chemicals & saline air

- Water Management: Perimeter fencing for treatment plants and reservoirs – rust-free performance reduces maintenance

- Metallurgy & Mining: Safe separation in tough outdoor environments, high impact & wear-resistance

- Public Infrastructure: Highways, railways, airports—modular install, rapid deployment

- Commercial & Residential: Sports courts, gardens, parks—custom colors and privacy options

| Type | Main Role | Technical Capability | Customization | Quality Control | Lead Time |

|---|---|---|---|---|---|

| Factory | Direct Production | Advanced: CNC, Automation, ISO-certified | High (Bespoke mesh/spec/packaging) | In-house testing (XRF, salt spray, fatigue) | 2–4 weeks |

| Manufacturer | OEM/ODM Production | Standard/Advanced | Medium–High | Random batch QC | 3–6 weeks |

| Supplier | Trade, Sourcing | Limited/Distributor | Standard Only | Documentary only | 4–8 weeks |

- Mesh Customization: Opening size, wire gauge, fence height, edge style (knuckle, twisted, barbed)

- Color Options: Original zinc or PVC in green, black, yellow, blue (RAL specified)

- Privacy Add-ons: Slats, fabric screens, security enhancers

- Project Support: CAD drawing & 3D visualization, on-site technical guidance

- Warranty: 10 years (material/workmanship); up to 25 years for premium hot-dip galvanized series

- After-sales: 24/7 online support, video install guides, free replacement for manufacturing defects

-

What is the typical material used in chain link fence from a galvanized steel fence factory?

Q195 or Q235 mild steel wire, with hot-dip galvanization per ISO 1461, ensuring high ductility and corrosion resistance. -

What wire gauge is standard, and how does it affect performance?

Standard diameters are 2.5mm to 4.0mm (BWG8–BWG12). Thicker wire means higher impact resistance and longer service. -

How is coating thickness assessed and why is it crucial?

Measured by XRF or magnetic gauges; ≥70μm meets most industrial standards (ASTM A641). Thicker coatings provide longer-term rust protection. -

What industry standards do leading galvanized steel fence manufacturers adhere to?

ISO 1461 for galvanization, ISO 9001 for QMS, ANSI/AWS D1.1 for welding, ASTM A392/A1165 for chain link fencing. -

Does salt spray test validate real-world corrosion resistance?

Yes; salt spray per ASTM B117 (500–1500 hours for hot-dip) simulates years of harsh weather exposure, confirming product durability. -

What installation standards are followed by professional galvanized steel fence suppliers?

Compliant with ASTM F668, EN 10223, and national specs. Structural posts and panel anchoring are tested for wind, impact & stability. -

How is quality controlled throughout production?

Full-process in-line inspection (diameters, welds, coating), plus lab salt spray/UV/bend/adhesion and random third-party audits (SGS, BV).

- Middle East – Oil Refinery (2022): Supplied 36km of 2.7mm hot-dip galvanized chain link fence (Building Wire Mesh). Passed 1200-hour salt spray, zero corrosion after 15 months. Contractor cited “quick on-site assembly & virtually maintenance-free operation.”

- USA – Hydroelectric Plant (2021): Custom 2.2m high, 3.6mm wire mesh. Factory cut production lead time to 2.5 weeks & provided digital installation guides. Customer rated “support 10/10” on service survey.

- EU – Rail Transit Depot (2023): Chain link fences with PVC top coating for improved weathering; decreased annual maintenance budget by 35% per facility manager's report.

Choosing a galvanized steel fence factory gives you access to the highest technical standards, tailor-made fencing, and factory-direct support. Our data, certification, and project benchmarks demonstrate why Building Wire Mesh outperforms typical suppliers in every metric that matters.

- [1] “Fencing Market Size, Share & Trends Analysis Report”, Grand View Research

- "Chain Link Fence, Galvanized Steel – Specification", ASTM A392

- "Hot-dip Galvanized Coatings on Fabricated Iron and Steel Articles", ISO 1461:2023

- "Expert Experiences on Durability of Metal Fencing", Engineering Tips Forum

This is the last article

-

Top Galvanized Steel Fence Factory - Durable & Customizable

NewsAug.01,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durability,Modular Design

NewsJul.31,2025

-

Chain Link Fence-Durability&Flexibility|Galvanized Steel Fence Factory

NewsJul.31,2025

-

Chain Link Fence - Anping County Puersen | Durability & Cost-Effective

NewsJul.31,2025

-

Chain Link Fence-Anping Puersen|Durable&Versatile

NewsJul.31,2025

-

Durable Welded Wire Mesh for Industrial Factories | AI Enhanced

NewsJul.31,2025