kol . 22, 2025 11:00 Back to list

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

Strategic Sourcing from a Leading Galvanized Steel Fence Factory

In the demanding landscape of industrial and infrastructural development, the integrity and longevity of perimeter security solutions are paramount. Companies, project managers, and governmental agencies continually seek robust, reliable, and cost-effective fencing. This often leads them to specialized manufacturers. The selection of a premier galvanized steel fence factory is a critical decision that impacts project timelines, budget adherence, and long-term asset protection. Galvanized steel fences, celebrated for their exceptional corrosion resistance and mechanical strength, represent a cornerstone in modern security and boundary demarcation across diverse sectors. Understanding the intricacies of their manufacture, application, and vendor capabilities is essential for informed procurement decisions.

This comprehensive guide delves into the world of galvanized steel fencing, offering insights into industry trends, technical specifications, and the nuanced advantages offered by leading manufacturers. Our focus is to equip B2B decision-makers and technical engineers with the knowledge necessary to procure high-performance fencing solutions that meet stringent project requirements and provide enduring value.

Current Industry Trends and Market Dynamics

The global market for galvanized steel fencing is experiencing sustained growth, driven by escalating infrastructure development, increasing demand for enhanced security, and the imperative for durable, low-maintenance materials. Key trends include:

- Sustainable Practices: A growing emphasis on environmentally friendly manufacturing processes and the use of recyclable materials, with steel being a highly recyclable commodity.

- Smart Fencing Integration: The incorporation of IoT sensors, CCTV, and access control systems into fence designs for advanced perimeter monitoring and security.

- Customization and Aesthetic Appeal: While functionality remains primary, there's a rising demand for customized designs, colors, and panel aesthetics that blend with architectural or environmental contexts.

- Enhanced Corrosion Protection: Beyond standard hot-dip galvanizing, hybrid coating systems (e.g., galvanizing followed by powder coating) are gaining traction for extended service life in extreme environments.

- Pre-fabricated Modular Solutions: An increase in demand for modular fence systems that facilitate rapid deployment and ease of installation, particularly for temporary or evolving site requirements.

According to industry reports, the global steel fence market is projected to reach approximately USD 12.5 billion by 2028, growing at a CAGR of 4.5% from 2023. This growth underscores the critical role that a sophisticated galvanized steel fence factory plays in supporting various industrial and construction initiatives worldwide.

The Manufacturing Process: A Deep Dive into a Galvanized Steel Fence Factory

The production of high-quality galvanized steel fences involves a meticulous, multi-stage process, ensuring optimal material performance and coating integrity. A reputable galvanized steel fence factory adheres to stringent quality controls at each step. The core processes involve:

1. Raw Material Selection and Preparation

High-grade carbon steel wire or sheet, typically conforming to ASTM A82 or equivalent international standards, is selected. These materials possess the necessary tensile strength and ductility for forming and welding. Incoming materials undergo chemical composition analysis and mechanical testing.

2. Fabrication (Wire Drawing, Welding, or Weaving)

- Wire Drawing: Steel rods are drawn through dies to achieve specific wire diameters required for mesh panels or framework components.

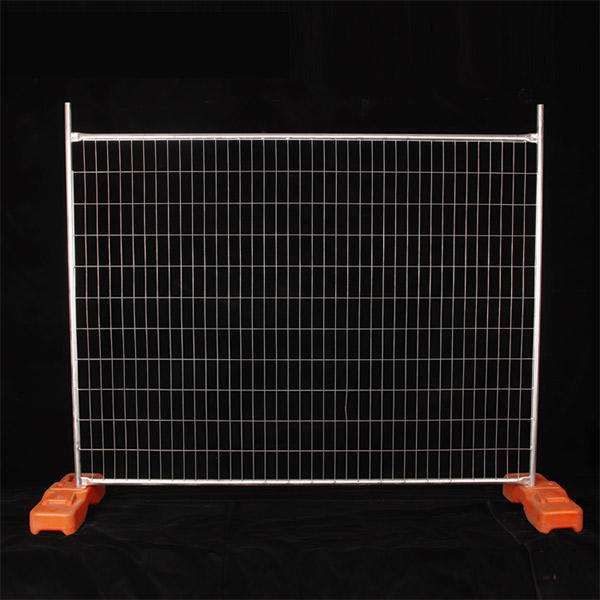

- Welding: For welded mesh fences (like Canana Temporary Fence), wires are precisely cut and then joined at intersections using automated resistance welding machines, ensuring strong, uniform welds. For frame structures, tubes and pipes are cut, bent, and then welded (e.g., TIG, MIG) to form panel frames and posts.

- Weaving: For chain link fences, wires are interwoven into the characteristic diamond pattern.

3. Surface Pre-treatment

This crucial stage prepares the steel surface for optimal zinc adhesion. It typically involves:

- Degreasing: Removal of oils, greases, and dirt using alkaline solutions.

- Pickling: Immersion in acidic solutions (hydrochloric or sulfuric acid) to remove rust and mill scale, exposing a chemically clean steel surface.

- Rinsing: Thorough washing to remove residual acids.

- Fluxing: Application of a flux solution (e.g., zinc ammonium chloride) to prevent oxidation before galvanizing and promote the metallurgical reaction between steel and molten zinc.

4. Hot-Dip Galvanizing

The cleaned and fluxed steel components are submerged into a bath of molten zinc at temperatures around 450°C (850°F). During this process, a metallurgical bond forms between the iron in the steel and the zinc, creating a series of zinc-iron alloy layers, topped by a layer of pure zinc. This provides both barrier and cathodic protection against corrosion.

5. Post-Galvanizing Treatment and Quality Control

After removal from the zinc bath, excess zinc is drained, and the components cool. Quality control measures include:

- Visual Inspection: Checking for smooth, uniform coating without bare spots or excessively thick areas.

- Coating Thickness Measurement: Using magnetic or eddy current gauges to ensure zinc coating meets specified standards (e.g., ISO 1461, ASTM A123/A123M). Typical coating thickness ranges from 60-100 microns (420-700 g/m²).

- Adhesion Testing: Assessing the bond strength of the zinc coating to the steel substrate.

- Dimensional Accuracy: Verifying panel dimensions, mesh sizes, and frame structures.

Service Life and Target Industries

The service life of hot-dip galvanized steel fences typically ranges from 20 to 50 years, often exceeding 70 years in mild rural environments, due to the slow corrosion rate of zinc. This exceptional durability makes them ideal for:

- Petrochemical: Security and demarcation in corrosive environments.

- Metallurgy: Robust barriers in heavy industrial settings.

- Water Supply & Drainage: Protection of critical infrastructure.

- Construction & Mining: Temporary and permanent site security.

- Power & Utilities: Enclosure of substations and generation facilities.

Advantages in these scenarios include superior corrosion resistance, minimal maintenance requirements, and overall long-term cost-effectiveness.

Technical Specifications and Product Parameters

Understanding the technical specifications of galvanized steel fences is crucial for ensuring they meet project-specific requirements for strength, durability, and compliance. The following table provides typical parameters for various galvanized fence types, including specifications often found in products like the Canana Temporary Fence from a leading galvanized steel fence manufacturers.

| Parameter | Welded Mesh Fence (e.g., Canana Temp Fence) | Chain Link Fence | Heavy Duty Panel Fence |

|---|---|---|---|

| Steel Grade | Q195, Q235 (Mild Steel) | Q195, Q235 (Mild Steel) | Q235B, S235JR (Structural Steel) |

| Wire/Tube Diameter | 3.0mm - 5.0mm (Mesh), 25mm - 48mm (Frame Tube) | 2.5mm - 4.0mm | 4.0mm - 8.0mm (Wire), 60mm - 80mm (Post) |

| Mesh Opening | 50x100mm, 60x150mm, 75x150mm | 50x50mm, 60x60mm, 75x75mm | 50x200mm, 50x100mm |

| Panel Height | 1.8m, 2.1m (customizable) | 1.2m - 3.0m | 1.8m - 3.0m |

| Panel Width | 2.4m, 2.9m (customizable) | Up to 6m (roll) | 2.5m, 3.0m |

| Zinc Coating Thickness | ≥42 µm (≥290 g/m²) - Hot-dip galvanized | ≥20 µm (≥140 g/m²) - Electro-galvanized or Hot-dip | ≥60 µm (≥420 g/m²) - Hot-dip galvanized |

| Tensile Strength (Wire) | 450-550 N/mm² | 350-550 N/mm² | 500-700 N/mm² |

| Compliance Standards | ISO 1461, ASTM A123, AS 4687 | ASTM A392, EN 10244-2 | EN 10223-4, EN 10244-2 |

These specifications highlight the robust nature of galvanized steel fencing, demonstrating why they are preferred for applications demanding high performance and longevity. The thickness of the zinc coating is a primary determinant of corrosion resistance and, consequently, service life, making it a critical parameter to evaluate when choosing products from various galvanized steel fence suppliers.

Technical Advantages of Galvanized Steel Fencing

The adoption of galvanized steel for fencing is not coincidental; it stems from a compelling array of technical advantages that directly address the rigorous demands of industrial and commercial environments. These advantages translate into significant long-term benefits:

- Superior Corrosion Resistance: Hot-dip galvanizing creates a multi-layered zinc-iron alloy coating that metallurgically bonds to the steel. This coating acts as a robust barrier, preventing corrosive elements from reaching the steel substrate. Even if the coating is scratched, the surrounding zinc sacrificially corrodes to protect the exposed steel (cathodic protection), significantly extending the fence’s lifespan compared to painted or electro-galvanized alternatives.

- Exceptional Durability and Strength: Steel itself provides inherent structural integrity and resistance to impact. The galvanizing process does not compromise the steel's mechanical properties, ensuring the fence can withstand harsh weather conditions, physical impacts, and prolonged exposure to various environmental stressors. This robust construction contributes to minimal deformation and long-term stability.

- Low Maintenance Requirements: Due to its inherent corrosion resistance, galvanized fencing requires minimal to no maintenance for decades. This significantly reduces operational costs associated with painting, rust removal, or replacement, offering substantial savings over the product's service life. This 'install and forget' aspect is highly valued in B2B applications.

- Cost-Effectiveness Over Lifetime: While the initial investment for galvanized steel fencing might be slightly higher than untreated or less durable options, its extended service life and negligible maintenance costs result in a far lower total cost of ownership (TCO). This makes it a financially prudent choice for long-term projects and assets.

- Aesthetic Retention: The zinc coating weathers uniformly, developing a stable, matte gray patina over time. This consistent appearance is preferable to the flaking, chipping, or fading often associated with painted finishes, maintaining a professional look without intervention.

- Ease of Inspection: The integrity of a galvanized coating can be visually assessed, and its thickness verified with non-destructive methods, simplifying quality assurance and long-term asset management.

These cumulative advantages underscore why investing in quality products from a dedicated galvanized steel fence factory is a strategic decision for any organization prioritizing durability, security, and long-term value.

Application Scenarios and Target Industries

The versatility and resilience of galvanized steel fences make them indispensable across a broad spectrum of industries and application scenarios. Their ability to withstand harsh environmental conditions, coupled with robust security features, positions them as a preferred choice for critical infrastructure and commercial projects.

- Construction Sites: Providing secure perimeters for temporary and long-term projects, preventing unauthorized access, ensuring worker safety, and safeguarding equipment. Products like the Canana Temporary Fence are specifically designed for rapid deployment and relocation on construction sites.

- Industrial and Manufacturing Facilities: Securing factory premises, warehouses, logistics hubs, and storage yards. The fences act as deterrents to theft and vandalism, delineating restricted areas and managing access control.

- Petrochemical and Energy Sector: Critical for securing refineries, power plants, solar farms, substations, and transmission lines. The corrosion resistance is vital in environments exposed to chemicals, high humidity, or coastal air, contributing to significant energy saving by reducing replacement cycles.

- Mining and Metallurgy Operations: Robust barriers are essential in these heavy-duty environments to manage access, protect hazardous zones, and withstand challenging conditions.

- Transportation Infrastructure: Securing airports, railway lines, highways, and ports. Galvanized fences offer reliable demarcation and anti-climb features, enhancing public safety and operational security.

- Water Supply & Drainage Systems: Protecting reservoirs, pumping stations, water treatment plants, and other sensitive public utilities from tampering and unauthorized entry, where corrosion resistance is paramount due to constant moisture exposure.

- Public Sector and Municipal Projects: Fencing for schools, parks, governmental buildings, and public facilities, offering durable and low-maintenance security solutions.

The core advantages of corrosion resistance and strength translate directly into prolonged service life and reduced operational expenditure across all these applications, making the products of a professional galvanized steel fence factory an economically sound investment.

Vendor Comparison: Selecting the Right Galvanized Steel Fence Supplier

Choosing among the myriad of galvanized steel fence suppliers requires a systematic approach. Not all manufacturers offer the same level of quality, service, or customization capabilities. Key criteria for evaluation include:

- Quality Certifications: Adherence to international standards like ISO 9001 (quality management), ISO 14001 (environmental management), and specific product standards (e.g., ISO 1461 for hot-dip galvanizing, ASTM A123).

- Production Capacity and Lead Times: The ability to fulfill large orders promptly and consistently, especially for projects with tight deadlines.

- Customization Capabilities: Flexibility in offering tailored solutions for unique project specifications, including custom dimensions, mesh types, post designs, and color finishes.

- Technical Expertise and R&D: A vendor's capacity for innovation, engineering support, and problem-solving. This includes experience with specific corrosive environments or high-security requirements.

- Customer Support and After-Sales Service: Responsiveness, technical assistance, installation guidance, warranty provisions, and availability of spare parts.

- Reputation and Client Portfolio: A proven track record with reputable clients in relevant industries, backed by positive testimonials and case studies.

| Characteristic | Hot-Dip Galvanizing (Post-Fabrication) | Pre-Galvanized (Zinc-Coated Wire) | Electro-Galvanizing |

|---|---|---|---|

| Coating Thickness | Thick (60-100 µm, 420-700 g/m²) | Medium (20-40 µm, 140-280 g/m²) | Thin (5-15 µm, 35-105 g/m²) |

| Corrosion Resistance | Excellent (20-50+ years) | Good (10-20 years) | Fair (5-10 years) |

| Edge/Weld Protection | Complete coverage, including cut edges and welds. | Welds and cut edges are exposed, prone to rust. | Minimal protection on welds and edges. |

| Application | Heavy-duty industrial, permanent installations, harsh environments. | General purpose, temporary fencing, lighter duty. | Indoor, light protection, aesthetic focus. |

| Cost (Relative) | Higher initial, lower TCO. | Medium. | Lower initial, higher TCO. |

This comparison highlights the significant difference in quality and performance between galvanizing methods, directly impacting the longevity and value proposition of the fence. Partnering with a specialized galvanized steel fence factory that utilizes hot-dip galvanizing after fabrication ensures superior protection and extended service life.

Customized Solutions and Project Engineering

Many projects require more than off-the-shelf solutions. A leading galvanized steel fence factory distinguishes itself by offering extensive customization and dedicated project engineering support. This ensures that the fencing solution precisely matches the unique functional, aesthetic, and regulatory requirements of each client.

Tailored Customization Options:

- Dimensions and Configurations: Custom panel heights, widths, mesh aperture sizes, wire diameters, and post specifications to fit irregular terrains or specific security levels.

- Gate Integration: Fabrication of custom swing gates, sliding gates, or cantilever gates, integrated seamlessly with the fence line, including provisions for automation and access control systems.

- Top Security Features: Addition of barbed wire, razor wire, anti-climb spikes, or specialized toppings for enhanced security against intrusion.

- Dual Coating Systems: Application of a powder coating layer over the hot-dip galvanized finish (Duplex System) for aesthetic appeal (RAL colors) and significantly enhanced corrosion protection in extremely aggressive environments.

- Post and Mounting Solutions: Custom post designs for specific soil conditions (e.g., concrete embedding, base plates for surface mounting), various fixing methods, and foundation types.

- Specialized Panels: High-security mesh panels (e.g., 358 mesh) with very small apertures to prevent foot- and hand-holds, making climbing extremely difficult.

Engineering and Design Support:

Beyond fabrication, a strong supplier provides:

- CAD Drawings and Blueprints: Detailed technical drawings for client review and approval.

- Structural Analysis: Ensuring fence designs can withstand specified wind loads, impact forces, or environmental stresses.

- Site Consultation: Expertise to assess site conditions and recommend optimal fencing solutions.

- Compliance Assurance: Guidance on meeting local building codes, safety regulations, and industry-specific standards.

This level of customization and engineering support is invaluable for complex industrial projects, ensuring that the chosen fencing system is not just a barrier, but an integral, optimized component of the overall security and operational infrastructure.

Application Case Studies and Customer Feedback

Real-world application demonstrates the tangible benefits of high-quality galvanized steel fencing. Here are illustrative case studies reflecting deployments from a leading galvanized steel fence factories:

Case Study 1: Large-Scale Industrial Plant Perimeter Security

- Client: Major petrochemical complex in a coastal region.

- Challenge: Secure a vast perimeter (10 km) against intrusion while withstanding extreme salt spray and humidity, ensuring a minimum 30-year service life with minimal maintenance.

- Solution: Installation of 2.4-meter high hot-dip galvanized welded mesh fence panels with integrated razor wire toppings and specialized corrosion-resistant fixings. Posts were concrete-embedded for maximum stability.

- Outcome: The project delivered a robust, high-security perimeter that exceeded client expectations for durability. Post-installation inspections confirmed uniform coating thickness and zero signs of rust after 5 years, projected to significantly surpass the 30-year requirement. Client feedback highlighted the ease of installation and the professional support provided during the design phase.

Case Study 2: Urban Infrastructure Development – Temporary Site Enclosure

- Client: Major civil engineering contractor for a multi-phase downtown revitalization project.

- Challenge: Rapid deployment and frequent reconfiguration of temporary fencing (Canana Temporary Fence equivalent) for construction zones in a high-traffic urban environment, requiring robust security and quick assembly/disassembly.

- Solution: A modular system of hot-dip galvanized temporary fence panels and stands, designed for interlocking connections without specialized tools. Gates were integrated for controlled access points.

- Outcome: The fencing solution allowed the contractor to efficiently manage site security through multiple project phases. The durability of the galvanized coating ensured the panels could be reused across several sites, minimizing waste and procurement costs. Project managers praised the modularity and strength, which facilitated quick adjustments to site layouts while maintaining a secure perimeter.

These cases exemplify how strategic collaboration with an experienced galvanized steel fence manufacturer leads to successful outcomes, providing reliable, long-lasting solutions for critical infrastructure and commercial projects.

Trustworthiness and Customer Assurance

Establishing trust is fundamental in B2B relationships. A reputable galvanized steel fence factory backs its products and services with transparent policies, robust quality assurance, and comprehensive customer support.

Frequently Asked Questions (FAQ)

- Q: What is the expected lifespan of a hot-dip galvanized steel fence?

- A: Typically 20-50 years, and often more, depending on environmental conditions (e.g., mild rural vs. aggressive coastal/industrial). The thick zinc coating provides long-term protection.

- Q: Can galvanized fences be customized for specific project needs?

- A: Absolutely. Reputable manufacturers offer extensive customization options, including dimensions, mesh types, post designs, gate integration, and additional coatings like powder coating for aesthetic or enhanced protection.

- Q: What testing standards do your products adhere to?

- A: Our products rigorously adhere to international standards such as ISO 1461 (for hot-dip galvanizing), ASTM A123/A123M, and relevant national standards like AS/NZS 4680, ensuring consistent quality and performance.

- Q: How do you ensure the quality of the galvanized coating?

- A: We implement a multi-stage quality control process, including visual inspection, magnetic/eddy current gauge testing for coating thickness, and adhesion tests on every batch. Our facilities are ISO 9001 certified.

Lead Time and Fulfillment

Our standard lead times for common galvanized fence products typically range from 2-4 weeks, depending on order volume. For customized solutions and large-scale projects, lead times are determined during the quotation phase, with detailed project schedules provided. We maintain robust supply chain management and efficient production lines to ensure timely delivery globally, leveraging strategic logistics partners for reliable fulfillment.

Warranty Commitments

We stand behind the quality of our galvanized steel fences with a comprehensive warranty. Our hot-dip galvanized products come with a minimum 10-year warranty against manufacturing defects and premature corrosion under normal environmental conditions, extending up to 25 years for specific product lines and applications. Specific warranty details are provided with each quotation.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We offer dedicated technical support, providing expert guidance on installation, maintenance, and product selection. Our after-sales team is available to address any inquiries or issues, ensuring long-term satisfaction and optimal performance of our fencing solutions. This includes access to replacement parts and technical documentation.

Conclusion: Partnering for Enduring Security Solutions

The decision to invest in galvanized steel fencing is a strategic one, aimed at ensuring long-term security, durability, and cost-efficiency. By prioritizing a reputable galvanized steel fence factory, B2B decision-makers can procure solutions that not only meet immediate project requirements but also offer decades of reliable performance with minimal maintenance. The blend of robust manufacturing processes, adherence to international standards, comprehensive technical advantages, and dedicated customer support culminates in a superior product offering.

As industries continue to evolve, the demand for resilient and adaptable perimeter security will only grow. Partnering with manufacturers who demonstrate expertise, experience, authoritativeness, and trustworthiness in galvanized steel production ensures that your investments are safeguarded, and your operational integrity is maintained. We invite you to explore the capabilities of leading manufacturers who are shaping the future of industrial fencing.

References

- International Organization for Standardization (ISO). ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. Geneva, Switzerland.

- ASTM International. ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. West Conshohocken, PA.

- American Galvanizers Association (AGA). The Durability of Hot-Dip Galvanizing. Retrieved from galvanized.com.

- NACE International. Corrosion Engineering: Principles and Practice. Houston, TX.

- Global Market Insights. Steel Fence Market Size. Retrieved from gminsights.com.

This is the last article

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025