آگوست . 02, 2025 03:00 Back to list

Welded Wire Mesh for Industrial Factory | Strength & Durability

As the industrial landscape evolves, welded wire mesh for industry factory has become a key material in sectors such as petrochemicals, metallurgy, water treatment, and civil engineering. This in-depth guide will lead you through the latest industry trends, product technical parameters, technology advantages, manufacturer comparisons, customized design, and real application cases, with authoritative data, vivid visualizations, and hands-on experience feedback.

I. Industry Overview & Trends: Welded Wire Mesh for Industry Factories

Global demand for welded wire mesh for industry factory has shown a strong upward trend. According to MarketsandMarkets, the welded wire mesh market surpassed USD 5.7 billion in 2023, with CAGR projected at 4.8% from 2024 to 2029, propelled by updates in manufacturing standards (ISO 9001:2015, ASTM A1064) and increased adoption for environmental, safety, and efficiency reasons.

Key Drivers:

- Stringent environmental & safety regulations driving quality upgrades.

- Persistence in anti-corrosion, strength, and modular installation for industrial diversities.

- Automation & CNC-driven precision in large-scale production by top welded wire mesh for industry manufacturers.

II. Technical Parameters & Data Table: Welded Wire Mesh for Industry Manufacturers

| Type | Mesh Opening (mm) | Wire Diameter (mm) | Coating Type | Standard | Tensile Strength (N/mm2) | Typical Use |

|---|---|---|---|---|---|---|

| Galvanized Welded Mesh | 25x25 / 50x50 | 2.5-4.0 | Hot-dip, Electric | ASTM A1064 | 400-550 | Fences, Enclosures |

| PVC Coated Welded Mesh | 50x50 | 3.0-5.0 | PVC/PE | ISO 9001, ANSI | 430-600 | Industrial Yards, Equipment Security |

| Stainless Welded Mesh | 25x25 / 100x100 | 2.0-6.0 | No Coating | ISO, SGS | 550-700 | Food, Pharma, Petrochemical |

III. Manufacture Process of Welded Wire Mesh for Industry Factory [With Diagram]

1. Raw Material Selection

High-quality low carbon steel, galvanized, or stainless steel wires (meeting ISO 16120-2) chosen for corrosion resistance and strength.

2. Straightening & Cutting

Automatic machines ensure precise straightening and cutting to exact mesh sizes, critical for uniformity in industrial use.

3. CNC Welding

Utilizing computer-controlled resistance welding (spot or line welding) to fuse intersecting wires, monitored by advanced sensors (CNC automation increases welding consistency & throughput).

4. Surface Treatment

Options include hot-dip galvanizing or PVC coating for enhanced anti-corrosion and durability; coatings conform to ASTM D3359 adhesion standards.

5. Cutting, Panelizing, Inspection

Panels are custom-cut, dimension-checked (±1.5%), surface inspected for defects (ISO 2859-1 sampling), then packaged for shipment.

Manufacture Process Flow Diagram

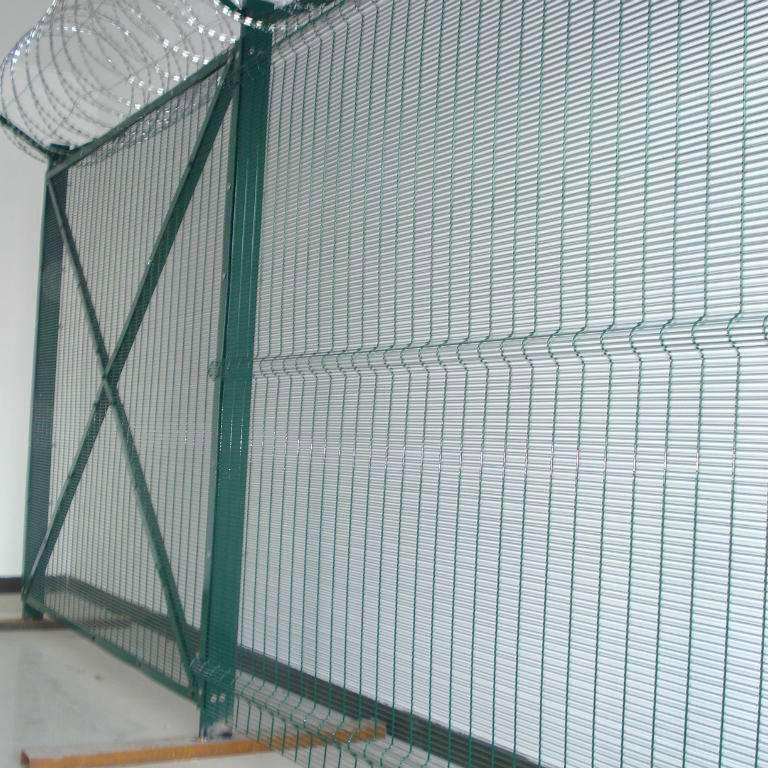

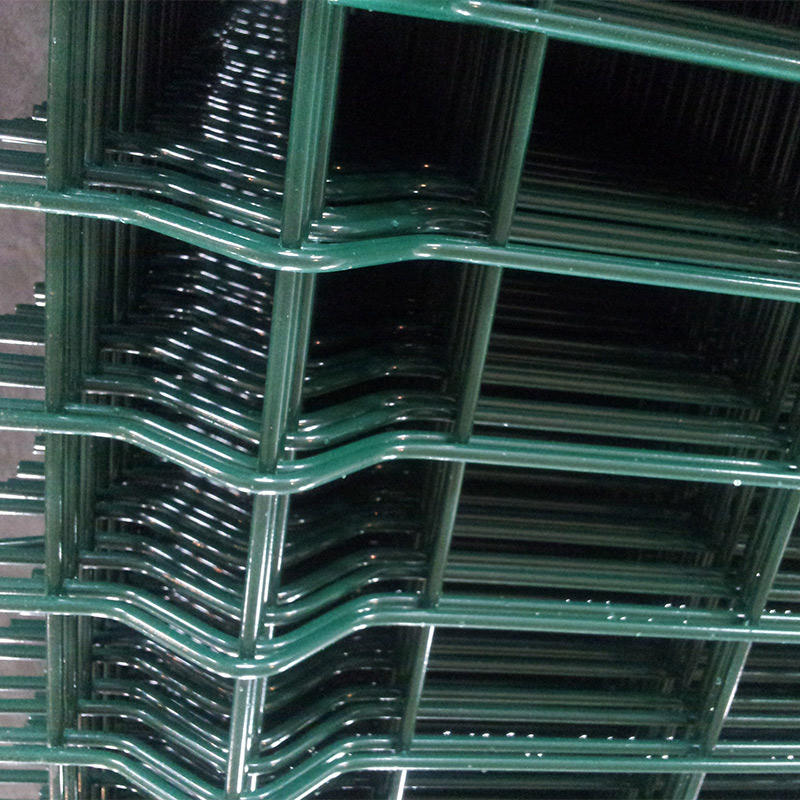

IV. Why Choose PVC Coated Welded Wire Panel?

Our PVC Coated Welded Wire Panel is engineered for high-demand industrial settings. This advanced mesh type is crafted through precision welding and subsequently covered with a durable PVC layer, offering extended service life, environmental resistance, and superior aesthetics.

- Material: High carbon steel + eco-friendly, UV-stabilized PVC.

- Manufacturing Standards: ISO 9001:2015, CE, ANSI/ASTM A1064.

- Process: Fully automated CNC grid welding, computer-monitored for uniformity.

- Corrosion Protection: Up to 3x the life of bare steel mesh, salt spray tested as per ISO 9227.

- Industries: Petrochemical, metallurgy, water treatment, power station, factory perimeters.

- Advantages: Impact resistance, eco-friendly, anti-aging, easy installation & color customization.

V. Specification & Performance Data Visualization

Core Technical Specifications - PVC Coated Welded Wire Panel

| Property | Standard Value | Test Method |

|---|---|---|

| Mesh Opening | 50 × 50 mm / 100 × 50 mm | GB/T 343 |

| Wire Diameter (after coating) | 3.6 mm / 4.2 mm / 5.0 mm | ISO 16120-2 |

| Tensile Strength | Min. 450 N/mm2 | EN 10223-7 |

| Coating Thickness | 0.7–1.2 mm | ASTM D6132 |

| Salt Spray Test (Corrosion) | ≥ 850 h | ISO 9227 |

| Color Customization | Green, Blue, Black, Custom | - |

| Width x Length (Panel) | 2.0 × 2.5 m / 2.5 x 3.0 m | Manual/Auto Inspection |

Performance Comparison Pie Chart

Service Life Line Chart

VI. Manufacturer & Supplier Comparison

| Criteria | Top Global OEM | Small-Scale Supplier | Self-Produced Brand |

|---|---|---|---|

| Certification | ISO, SGS, ANSI, CE | ISO Partial | ISO, Internal Audit |

| Product Range | Full (galvanized, PVC, SS) | PVC & galvanized | Mainly PVC, Galva |

| Tech Process | Fully CNC, robot QC | Manual, semi-auto | CNC grid weld, QC |

| Lead Time | 14-21 days | 21-35 days | 18-23 days |

| Order Customization | OEM/ODM, bulk & odd sizes | Limited | OEM/ODM |

| Warranty & Support | 5-10 years, global support | 2-3 years, local | 5 years, 7x24h online |

VII. Custom Solutions & Application Scenarios

- OEM Manufacturing: Custom mesh size, wire gauge, and color on demand

- Project Design: Collaborate with EPC & consultant teams for industrial facilities

- Compliance: Match local, national, and international standards (ASTM, ISO, CE, ANSI)

- Petrochemical Plant: Anti-corrosive, high-strength perimeter panels

- Metallurgical Industry: Safety enclosures for hazardous material zone

- Municipal Water Engineering: Easy-wash intake guards & tank enclosures

- Factory Perimeter Security: Long-life, UV-resistant boundary fencing

- Warehouse Storage: Custom racks and mesh partitions for safe storage

VIII. Typical Projects & Customer Feedback

“We sourced PVC coated welded wire mesh for our industry factory upgrade (Q1 2024) — performance surpassed expectations in both corrosion resistance and installation speed. Certified to ISO, warranted for 8 years, top choice for Middle East climates.”

- Engineering Manager, Saudi National Gas

- Project: Qatar Petrochemical Complex

- 78,000 sqm perimeter, special grey PVC mesh, EN 10223 compliance, 6 years no-maintenance record - Project: Swiss Municipal Waterworks

- Custom dimensions, anti-algae coating, ISO 9227 corrosion trial passed

IX. FAQ: Professional Terms on Welded Wire Mesh for Industry Factory

- Q1: What base material is used for industrial welded wire mesh panels?

- Typically, low-carbon steel (meeting ISO 16120-2) for regular meshes; stainless steel (AISI 304/316) for high-corrosion or food/pharma use, and hi-tensile galvanized steel for heavy load or long-span requirements.

- Q2: What is “mesh aperture size” and why choose 50x50mm or 100x50mm?

- Mesh aperture (opening) refers to the distance between welded intersections. 50x50mm is widely adopted for human safety and animal exclusion; 100x50mm is for high-visibility, low-risk sectors to save weight and cost.

- Q3: What are relevant international standards for welded mesh in industry?

- Key specs: ISO 9001:2015 for quality, ASTM A1064 & EN 10223 for welded mesh, ISO 9227 for salt spray (corrosion), ASTM D3359 for coating adhesion.

- Q4: How is the “PVC coating” applied and tested?

- Coating is extruded or sprayed over welded mesh and cured at high temperature. Thickness (0.7-1.2mm) and adhesion tested to ASTM D3359, with appearance/defects checked as per ISO 2859-1 standards.

- Q5: Can welded wire mesh for industry factories be delivered custom-sized?

- Yes. OEM/ODM facilities cut mesh to length, width, aperture, and color as per CAD or tender drawings.

- Q6: What is the typical installation standard for industrial settings?

- Install according to ISO 1461 (for galvanized) and manufacturer’s panel/post system; anchor systems should withstand wind loads per EN 1991-1-4; all supports must bear panel weight with 1.5x safety factor.

- Q7: What is the product warranty and after-sales service?

- Industrial-grade PVC coated welded wire mesh panels generally offer 5–10 years warranty against UV, corrosion, and welding defects, with 7x24h customer service and local technical guidance.

X. Delivery, Warranty, and Customer Support

- Production/Deliery Cycle: 14–21 days for popular sizes; up to 30 days for OEM batch or large tenders.

- Warranty: 5–10 years (documented on order), complies with ISO and EN requirements.

- Technical Support: 24/7 inquiry line, drawing assistance, and on-site guidance if requested.

References, Industry Sources & Further Reading

- MarketsandMarkets, Welded Wire Mesh Market Research Report 2024

- ISO Standards: ISO 16120-2:2023, Steel wire for industrial mesh

- American Wire Producers Association, Technical Sheets, 2024, www.awpa.org

- LinkedIn, Top 10 Welded Wire Mesh Manufacturers Worldwide (2023 Update)

- Construction Product Review, Jan. 2024, Welded Wire Mesh Applications in Modern Industry

For academic discussion and user experience sharing, recommended forum: Eng-Tips - Industrial Mesh Forum

This is the last article

-

Welded Wire Mesh for Industrial Factory | Strength & Durability

NewsAug.02,2025

-

Top Galvanized Steel Fence Factory - Durable & Customizable

NewsAug.01,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durability,Modular Design

NewsJul.31,2025

-

Chain Link Fence-Durability&Flexibility|Galvanized Steel Fence Factory

NewsJul.31,2025

-

Chain Link Fence - Anping County Puersen | Durability & Cost-Effective

NewsJul.31,2025

-

Chain Link Fence-Anping Puersen|Durable&Versatile

NewsJul.31,2025