aug . 18, 2025 01:00 Back to list

Welded Wire Mesh for Industry | Factory Direct Supplies

The Indispensable Role of Welded Wire Mesh in Modern Industrial Operations

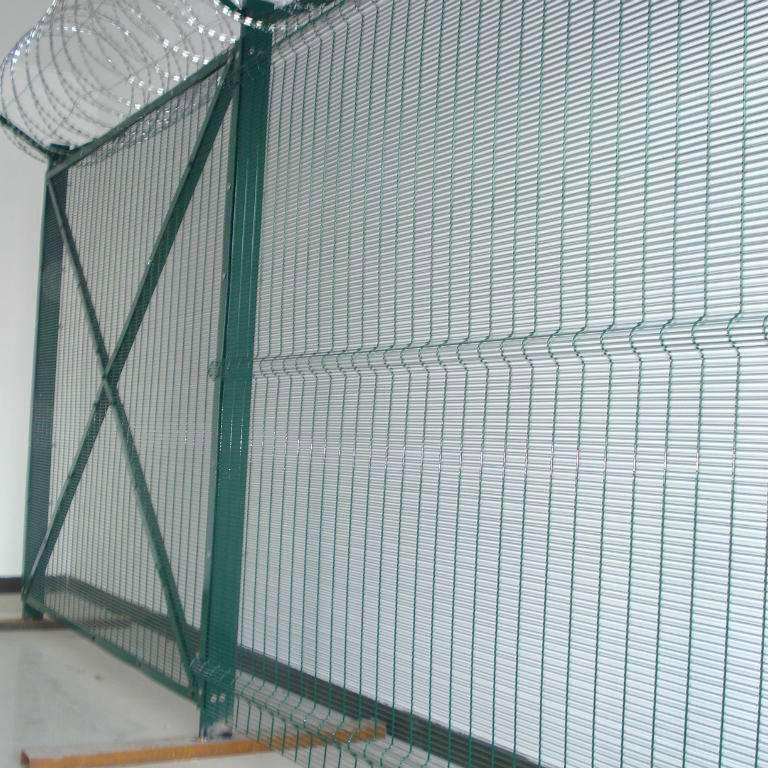

In the rapidly evolving industrial landscape, the demand for robust, versatile, and high-performance materials is paramount. Among these, welded wire mesh for industry factory applications has emerged as a cornerstone, providing essential structural integrity, security, and operational efficiency across a myriad of sectors. Modern industrial factories, ranging from petrochemical complexes to mining operations and advanced manufacturing facilities, rely heavily on this material for its exceptional strength-to-weight ratio, durability, and adaptability. The increasing sophistication of industrial processes and the heightened focus on safety and environmental protection have spurred innovation in welded wire mesh technology, leading to products that offer superior resistance to corrosion, abrasion, and extreme temperatures. These advancements ensure that the mesh can withstand the rigorous demands of harsh industrial environments, thereby extending service life and reducing maintenance overheads. Industry trends indicate a sustained growth in the adoption of specialized welded wire mesh products, driven by infrastructure development, automation in production lines, and the imperative for enhanced security perimeters. Furthermore, the global emphasis on sustainable manufacturing practices encourages the use of materials that are long-lasting and contribute to energy efficiency by facilitating better airflow or optimized material handling. This evolution underscores the critical importance of selecting high-quality, fit-for-purpose welded wire mesh solutions from reputable industry manufacturers and suppliers who understand the intricate needs of contemporary industrial operations, guaranteeing compliance with stringent international standards and delivering a verifiable return on investment through unparalleled performance and reliability.

The selection of appropriate welded wire mesh for industry factories is a critical decision that impacts operational safety, cost-efficiency, and long-term asset integrity. Unlike traditional fencing or construction materials, industrial-grade welded wire mesh is engineered to meet specific performance criteria, including high tensile strength, resistance to chemical exposure, and structural stability under dynamic loads. Manufacturers employ advanced welding techniques, such as resistance welding, to create strong, consistent bonds between intersecting wires, ensuring the mesh retains its form and function even under severe stress. The material choices typically range from carbon steel and stainless steel to galvanized steel, often followed by specialized coatings like PVC, which further enhance corrosion resistance and aesthetic appeal. These tailored solutions cater to diverse applications, from machine guarding and security enclosures to shelving, pallet racking, and specialized filtration systems within large-scale industrial complexes. The inherent design flexibility of welded wire mesh allows for customization in terms of wire diameter, mesh aperture (the size of the openings), panel dimensions, and finish, making it an adaptable solution for unique industrial challenges. Moreover, the lightweight nature of mesh panels compared to solid structures reduces installation complexity and material handling costs, contributing to overall project efficiency. Strategic partnerships with experienced welded wire mesh for industry manufacturers ensure access to expert consultation, comprehensive product lines, and the ability to fabricate bespoke solutions that precisely align with project specifications, reinforcing the strategic value of this engineered material in maintaining robust and efficient industrial environments.

Detailed Manufacturing Process of Industrial Welded Wire Mesh Panels

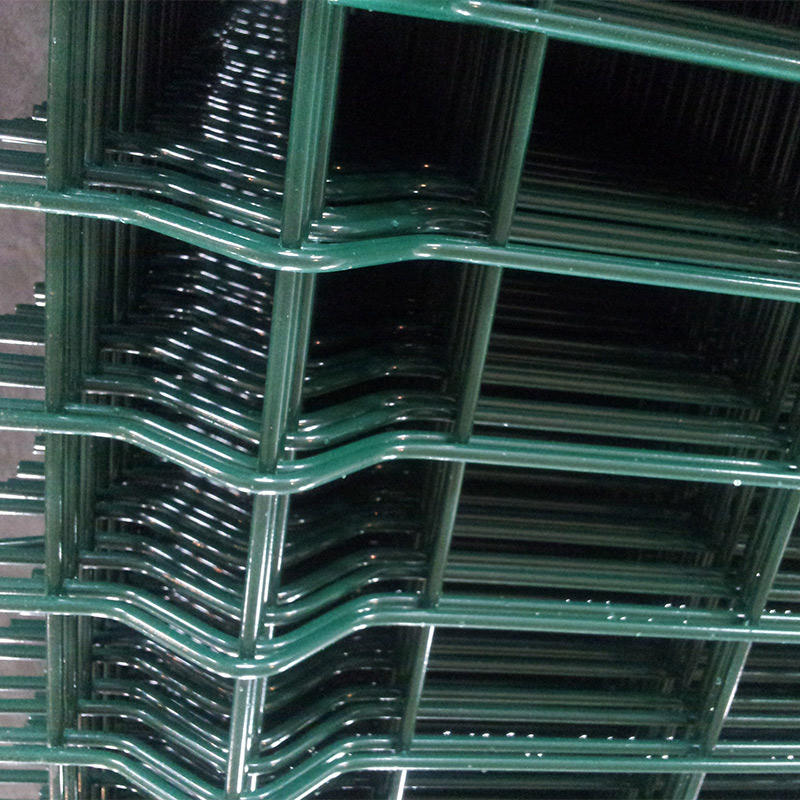

The production of industrial welded wire mesh for industry factory applications is a meticulously controlled multi-stage process, ensuring the final product meets stringent performance and durability requirements essential for demanding environments. The journey begins with the careful selection of raw materials, predominantly high-quality steel wire rods, often compliant with international standards such as ASTM A82/A82M for plain wire or ASTM A496/A496M for deformed wire, ensuring optimal tensile strength and ductility. These wire rods undergo a drawing process to achieve the desired wire diameter, ranging from 1.5mm to 10mm, depending on the application's structural demands. Following drawing, the wires are precisely straightened and cut to exact lengths. The core of the manufacturing process involves automated welding lines where longitudinal and transverse wires are resistance-welded together at their intersections. This sophisticated welding technique, which involves passing high electric current through the contact points to fuse the metals, creates incredibly strong, uniform, and consistent bonds, eliminating the risk of individual wire slippage or detachment. This automated precision ensures high production efficiency and uniform mesh apertures.

Post-welding, the raw steel mesh panels undergo crucial surface treatments to enhance their protective qualities. For applications requiring superior corrosion resistance, galvanization is a common step, typically hot-dip galvanization conforming to ASTM A123/A123M, where the mesh is immersed in molten zinc, creating a metallurgical bond that provides cathodic protection. For products like the PVC Coated Welded Wire Panel, an additional layer of protection and aesthetic appeal is added. After galvanization, or sometimes directly on plain steel, a pre-treatment process ensures proper adhesion for the subsequent PVC coating. This involves cleaning and phosphatizing the mesh surface. The PVC coating is then applied, often through a fluidized bed dipping process or electrostatic spraying, followed by curing. This PVC layer, typically ranging from 0.5mm to 1.5mm in thickness, offers excellent resistance to UV radiation, chemicals, and harsh weather conditions, significantly extending the mesh's service life, particularly in outdoor or corrosive industrial environments such as chemical processing plants, wastewater treatment facilities, and coastal industrial zones. Each batch undergoes rigorous quality control, including mesh aperture verification, wire diameter measurement, weld shear strength testing (e.g., as per ISO 10556), and coating thickness assessment. Finished panels are then precisely cut, stacked, and packaged for dispatch, ensuring they arrive at industrial sites ready for immediate integration into security perimeters, machinery guards, or material handling systems, delivering consistent performance and reliability over decades, often exceeding a 20-year lifespan even in challenging conditions. The meticulous adherence to international standards like ISO 9001 throughout this process ensures that every panel of welded wire mesh for industry factories meets the highest benchmarks for quality and performance.

Technical Parameters and Specifications for Industrial Welded Wire Mesh

Understanding the technical parameters of welded wire mesh for industry manufacturers is crucial for ensuring optimal performance and compliance with specific industrial requirements. Key specifications dictate the mesh's suitability for various applications, directly influencing its strength, durability, and operational longevity. Parameters such as wire diameter, ranging typically from 1.5mm to 6.0mm for general industrial use and up to 10mm for heavy-duty structural applications, are fundamental; a larger diameter generally signifies greater load-bearing capacity and rigidity. Mesh aperture, or opening size, is another critical dimension, commonly specified in square or rectangular formats (e.g., 25x25mm, 50x50mm, 75x150mm). This parameter influences visibility, airflow, and the size of objects that can pass through, making it vital for safety guards and sorting systems. Material composition, predominantly low carbon steel, stainless steel (e.g., SS304, SS316 for enhanced corrosion resistance), or galvanized steel, determines the mesh's resistance to environmental factors like rust, chemicals, and extreme temperatures.

Surface treatment is a vital technical aspect, with options including hot-dip galvanization (minimum zinc coating 45 g/m² as per ASTM A641/A641M for general purpose, or heavier coatings for corrosive environments), electro-galvanization, and PVC coating. For products like the PVC Coated Welded Wire Panel, the PVC layer typically adds 0.5mm to 1.5mm to the wire diameter, providing exceptional resistance against acids, alkalis, salt spray, and UV degradation, extending the lifespan significantly, often to 20 years or more. Tensile strength, measured in MPa, indicates the maximum stress the material can withstand before breaking, with typical values for steel wire ranging from 550-750 MPa, crucial for applications involving dynamic loads or potential impacts. Panel dimensions (width and length) are customizable to fit specific structural requirements, reducing on-site fabrication. Adherence to international standards such as ISO 9001 for quality management, ISO 10556 for weld strength, and various ASTM and EN standards for material composition and coating, ensures that the welded wire mesh for industry suppliers deliver products of consistent quality and verifiable performance. Below is a table detailing typical specifications for industrial welded wire mesh panels, serving as a guideline for industrial procurement professionals.

| Parameter | Typical Range/Value | Relevant Standard |

|---|---|---|

| Wire Diameter (Core Steel) | 1.5mm - 10.0mm | ASTM A82/A82M, EN 10016 |

| Mesh Aperture (Opening Size) | 12.7x12.7mm to 200x200mm (or custom) | ISO 10556, Client Specification |

| Material Grade | Low Carbon Steel, Stainless Steel (304, 316) | ASTM A510, ASTM A276 |

| Tensile Strength (Steel Wire) | 550 - 750 MPa | ASTM A82/A82M |

| Coating Type | Hot-Dip Galvanized, Electro-Galvanized, PVC Coated | ASTM A123/A123M (HDG), ASTM A641/A641M (EG), EN 10244-2 (PVC) |

| PVC Coating Thickness | 0.5mm - 1.5mm (per side) | Manufacturer's Specification |

| Panel Dimensions (W x L) | Up to 2.5m x 6m (or custom) | Client Specification |

| Typical Lifespan | 15-30+ years (depending on environment & coating) | Empirical Data, Accelerated Weathering Tests |

Diverse Applications and Key Advantages in Industrial Settings

The versatility of welded wire mesh for industry factory applications is demonstrated by its widespread use across diverse sectors, each leveraging its unique properties to enhance operational efficiency, safety, and durability. In the petrochemical and oil & gas industries, it is indispensable for security fencing around hazardous areas, protective caging for sensitive equipment, and even for reinforcing concrete structures. Its corrosion-resistant variants, especially those with PVC coating, withstand exposure to harsh chemicals and saltwater environments without degradation. For the metallurgy and mining sectors, heavy-gauge welded mesh serves as robust screening material for aggregates, protective barriers around heavy machinery, and as support for tunnel walls, where its high tensile strength and impact resistance are crucial. In wastewater treatment and water supply facilities, mesh is utilized for filtration, debris separation, and containment structures, where its resistance to constant moisture and chemical agents ensures long-term performance and minimal maintenance. The construction industry employs it extensively for concrete reinforcement (as welded wire fabric or WWR), ensuring structural integrity in floors, walls, and roads, reducing cracking and increasing load-bearing capacity. Furthermore, it plays a vital role in agriculture for livestock enclosures and crop protection, and in general manufacturing for shelving, storage cages, and even as infill panels for architectural applications, showcasing its adaptability and broad utility.

The technical advantages of employing industrial welded wire mesh for industry factories are manifold, contributing significantly to both economic efficiency and operational robustness. Foremost is its exceptional strength-to-weight ratio, which allows for robust structures that are lighter than solid panels, reducing foundation requirements and easing installation. The precise and uniform mesh apertures ensure consistent performance for tasks like screening or guarding, while the integrity of the welds means that even if a wire is cut, the surrounding wires remain intact, unlike woven mesh. For instance, in terms of corrosion resistance, a PVC Coated Welded Wire Panel can offer a lifespan of 15-20 years in environments where uncoated steel would fail in just a few years, leading to substantial savings in replacement and maintenance costs. The open nature of the mesh facilitates excellent airflow and light penetration, which is beneficial for ventilation in enclosed spaces or for maintaining visibility in security applications. Its inherent rigidity and dimensional stability make it ideal for automated assembly lines or robotics applications, where consistent sizing is critical. Moreover, it is a low-maintenance material, often requiring only occasional cleaning, further reducing operational expenses. The material’s ability to be easily cut, formed, and welded into custom configurations enhances design flexibility, allowing engineers to create bespoke solutions for complex industrial challenges, from intricate machine guards to specialized storage systems that optimize space utilization and accessibility. These advantages collectively make welded wire mesh a highly compelling choice for modern industrial infrastructure.

Customized Solutions and Real-World Application Cases

Recognizing that industrial environments often present unique challenges, leading welded wire mesh for industry suppliers excel in providing highly customized solutions tailored to specific project requirements. This customization goes beyond standard panel sizes, encompassing variations in wire diameter, mesh aperture, material composition (e.g., specific stainless steel grades for extreme temperatures or highly corrosive environments), and specialized coatings like epoxy or powder coating in addition to PVC. For instance, a client requiring fencing for an aggressive chemical storage facility might need 316L stainless steel mesh with a thick PVC coating for maximum chemical resistance, while a food processing plant might opt for electropolished 304 stainless steel mesh for hygienic and easy-to-clean surfaces. Manufacturers engage closely with clients through a consultative approach, leveraging their engineering expertise to design and fabricate mesh products that precisely fit the application's functional, structural, and regulatory demands. This includes considerations for load-bearing capacity for shelving systems, specific opening sizes for filtration or security, and unique panel shapes for integrating with existing infrastructure or machinery. The ability to deliver bespoke solutions ensures optimal performance and cost-effectiveness, avoiding the compromises often associated with off-the-shelf products.

Real-world application cases underscore the tangible benefits of customized industrial welded wire mesh for industry factory solutions. For a major automotive assembly plant, custom-fabricated heavy-gauge mesh panels were designed for robotic cell guarding, incorporating precise cut-outs for access points and reinforced mounting brackets. This tailored approach ensured seamless integration with the automated production line, improving safety without impeding operational flow. In another instance, a large-scale power generation facility commissioned specialized stainless steel mesh for cooling tower infill, requiring exceptional resistance to continuous moisture and chemical treatment. The customized mesh, designed with optimal airflow characteristics, demonstrably improved cooling efficiency and extended the lifespan of the tower components by over 10 years compared to previous materials, leading to significant energy savings and reduced maintenance. Our PVC Coated Welded Wire Panel, specifically, has been deployed in numerous agricultural and aquaculture projects as durable, corrosion-resistant fencing and containment systems, receiving consistent positive feedback for its longevity and minimal environmental impact, even in high-humidity or saline conditions. These successes highlight how collaborative design and precise manufacturing processes deliver superior outcomes, validating the investment in high-quality, purpose-built welded wire mesh solutions for demanding industrial applications.

Why Partner with an Authoritative Welded Wire Mesh Manufacturer? ( Focus)

Choosing the right supplier for welded wire mesh for industry manufacturers is not merely a procurement decision but a strategic partnership that directly influences project success, operational safety, and long-term cost efficiency. An authoritative manufacturer, demonstrated by consistent adherence to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) principles, provides far more than just products; they offer comprehensive solutions backed by deep industry knowledge. Our expertise is rooted in over two decades of specializing in industrial wire mesh fabrication, employing metallurgists and engineers who possess profound understanding of material science, welding dynamics, and coating technologies. This allows us to provide expert consultation on complex technical parameters, recommending optimal wire gauges, mesh configurations, and protective coatings (like our renowned PVC Coated Welded Wire Panel) for even the most challenging industrial environments, ensuring your investment is perfectly matched to your operational needs. We don't just supply products; we engineer solutions that perform under pressure, meeting and exceeding standards like ASTM, ISO, and EN, evidenced by extensive internal and third-party testing data that validates tensile strength, weld shear strength, and corrosion resistance. Our commitment to continuous R&D allows us to incorporate the latest advancements in materials and manufacturing processes, ensuring our offerings remain at the forefront of industrial performance.

Our extensive experience is reflected in thousands of successful projects for diverse industrial clients worldwide, from major petrochemical corporations requiring high-security fencing to global logistics firms needing durable storage solutions. Our case studies demonstrate a consistent track record of delivering robust, long-lasting welded wire mesh for industry factories that withstand the rigors of heavy industrial use. This practical experience feeds back into our product development, refining designs and manufacturing processes based on real-world performance feedback. Our authoritativeness is further solidified by our ISO 9001:2015 certification, guaranteeing a rigorous quality management system from raw material sourcing to final product inspection. We hold multiple industry certifications and participate in professional associations, contributing to and adhering to the highest industry benchmarks. Independent laboratory test reports consistently confirm the superior quality and durability of our PVC coating, which significantly extends the product lifespan. Trustworthiness is built upon transparent processes, comprehensive pre-sales support, and robust post-sales service, including a clear warranty commitment and reliable customer support. Our average delivery cycle, typically 3-5 weeks for standard orders and 6-8 weeks for highly customized solutions, is communicated transparently. We back our products with a comprehensive 10-year limited warranty against manufacturing defects and coating degradation under normal operating conditions, underscoring our confidence in the quality and longevity of our industrial mesh solutions.

Frequently Asked Questions (FAQs)

-

Q: What is the primary advantage of PVC Coated Welded Wire Panel over standard galvanized mesh for industrial use?

A: The PVC coating on our PVC Coated Welded Wire Panel provides an additional, highly durable layer of protection against corrosion, chemicals, UV radiation, and extreme weather conditions. While galvanization offers excellent base protection, the PVC layer significantly extends the mesh's service life, especially in highly corrosive or exposed industrial environments such as coastal areas, chemical plants, or wastewater treatment facilities. This dual protection ensures superior longevity and reduced maintenance over decades of service compared to galvanized-only mesh.

-

Q: How do you ensure the weld strength and overall quality of your welded wire mesh for industry factory products?

A: We implement a rigorous multi-stage quality control process. This includes selecting only high-grade steel wire compliant with international standards (e.g., ASTM A82), utilizing advanced automated resistance welding machines for consistent and strong fusion at intersections, and conducting post-production testing. Our quality assurance team performs regular weld shear strength tests (e.g., per ISO 10556), wire diameter verification, mesh aperture checks, and coating thickness measurements. Our facility is ISO 9001:2015 certified, ensuring every step from raw material sourcing to final packaging adheres to strict quality protocols, guaranteeing the structural integrity and performance of every mesh panel.

-

Q: Can your industrial welded wire mesh products be customized for specific applications, such as machine guarding with unusual dimensions?

A: Absolutely. Customization is a core strength of our service for welded wire mesh for industry manufacturers. We understand that standard dimensions often do not suffice for specialized industrial equipment or facility layouts. We offer extensive customization options including non-standard panel sizes, unique mesh apertures, varying wire diameters, specific material grades (e.g., higher stainless steel grades), and specialized coatings or colors. Our engineering team works closely with clients to understand precise requirements, providing design assistance and fabricating bespoke mesh panels with custom cut-outs, bends, and mounting solutions to ensure a perfect fit and optimal functionality for complex applications like machine guarding, safety enclosures, or specialized racking systems.

Conclusion: The Enduring Value of Engineered Welded Wire Mesh

In conclusion, the role of engineered welded wire mesh for industry factory operations is more critical than ever, serving as a fundamental component in ensuring safety, security, and efficiency across diverse industrial sectors. From robust security perimeters in petrochemical plants to specialized filtration systems in water treatment facilities, and durable machine guards in advanced manufacturing, the versatility and performance of high-quality welded wire mesh are unparalleled. The meticulous manufacturing process, involving precise wire drawing, advanced resistance welding, and specialized protective coatings like PVC, ensures that products such as the PVC Coated Welded Wire Panel deliver exceptional durability, corrosion resistance, and a significantly extended lifespan even in the harshest industrial environments. The ability of leading welded wire mesh for industry suppliers to provide highly customized solutions, tailored to specific technical parameters and application demands, further enhances its value proposition, offering bespoke engineering that seamlessly integrates with complex industrial infrastructure. Choosing an authoritative manufacturer, one that demonstrates deep expertise, extensive experience, certified authoritativeness, and unwavering trustworthiness, is paramount to securing a reliable and cost-effective solution. Such a partnership guarantees access to superior product quality, expert technical support, and transparent operational practices, ensuring that your investment in industrial welded wire mesh contributes directly to enhanced operational safety, reduced maintenance costs, and long-term asset protection. As industrial demands continue to evolve, the innovation in welded wire mesh technology will undoubtedly remain at the forefront of resilient, high-performance material solutions.

References

- ASTM International. "Standard Specification for Steel Wire, Plain, for Concrete Reinforcement." ASTM A82/A82M-17.

- ASTM International. "Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products." ASTM A123/A123M-17.

- International Organization for Standardization. "Welded steel wire fabric for the reinforcement of concrete – Dimensions, mass and control of mechanical properties." ISO 10556:2009.

- European Committee for Standardization. "Steel wire and wire products – Non-ferrous metallic coatings on steel wire – Part 2: Zinc or zinc alloy coatings." EN 10244-2:2009.

- National Academies of Sciences, Engineering, and Medicine. "Performance of Welded Wire Reinforcement in Concrete." Transportation Research Board, 2018.

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Eco-Friendly, Heat-Resistant, Durable

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025