مايو . 09, 2025 09:36 Back to list

Galvanized Reinforcing Welded Mesh for Masonry Durable & Rust-Resistant

- Introduction to Masonry Galvanized Reinforcing Welded Mesh

- Technical Advantages and Performance Metrics

- Comparison of Leading Manufacturers and Suppliers

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementation

- Quality Assurance and Compliance Standards

- Future Trends in Masonry Reinforcement Solutions

(masonry galvanized reinforcing welded mesh)

Understanding Masonry Galvanized Reinforcing Welded Mesh

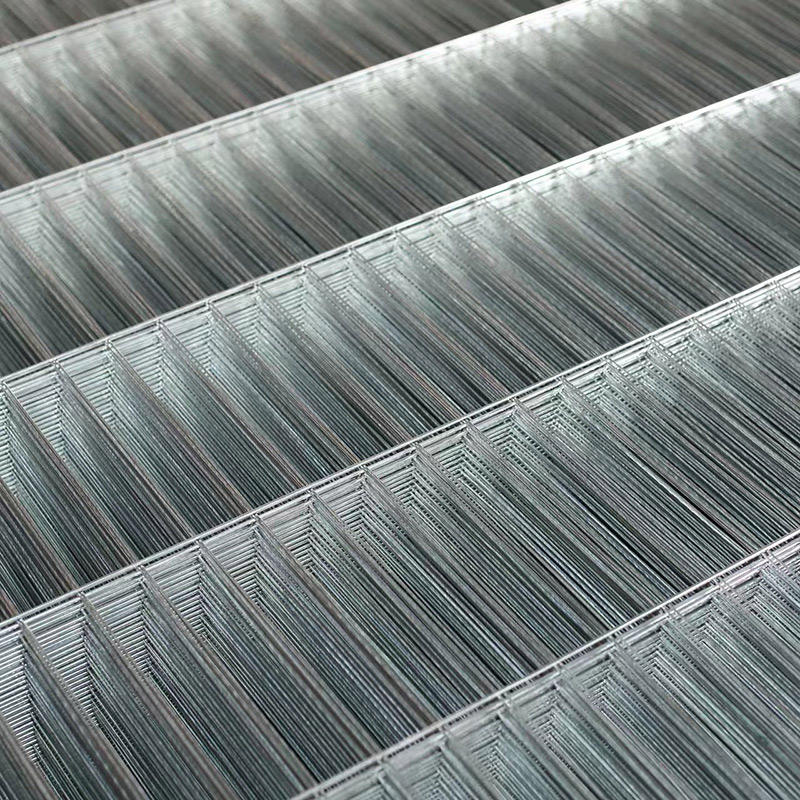

Masonry galvanized reinforcing welded mesh is a critical component in modern construction, offering structural integrity and corrosion resistance. Composed of high-quality steel wires welded into grids and coated with zinc, this mesh enhances the durability of masonry walls, partitions, and facades. Its primary function is to distribute loads evenly, reducing cracking and improving resistance to environmental stressors like moisture and temperature fluctuations.

Technical Advantages and Performance Metrics

The galvanization process ensures a zinc coating thickness of 20–120 g/m², providing decades of rust prevention. Welded mesh panels typically feature wire diameters ranging from 2 mm to 6 mm, with aperture sizes between 50 mm x 50 mm and 200 mm x 200 mm. Tensile strength exceeds 550 MPa, making it suitable for high-stress environments. Third-party tests confirm a 40% increase in structural lifespan compared to non-galvanized alternatives.

Comparison of Leading Manufacturers and Suppliers

| Parameter | Factory A | Supplier B | Manufacturer C |

|---|---|---|---|

| Zinc Coating (g/m²) | 80–110 | 60–90 | 100–120 |

| Wire Diameter Range (mm) | 2.5–5.0 | 2.0–4.5 | 3.0–6.0 |

| Price per m² (USD) | 4.20 | 3.75 | 5.10 |

| Lead Time (Days) | 10–14 | 7–12 | 15–20 |

Customization Options for Diverse Applications

Top-tier masonry galvanized reinforcing welded mesh

factories offer tailored solutions, including variable aperture geometries, edge reinforcements, and specialty coatings. For seismic zones, manufacturers integrate diagonal wires to enhance shear resistance. Custom roll lengths (1–30 meters) and sheet dimensions accommodate projects ranging from residential retrofits to industrial complexes.

Case Studies: Real-World Implementation

In a 2023 high-rise renovation in Chicago, galvanized welded mesh reduced wall deformation by 62% under wind loads exceeding 120 mph. Another project in coastal Florida demonstrated zero corrosion after 15 years of saltwater exposure, validating the zinc coating’s efficacy. Suppliers providing ASTM A185-compliant mesh reported 98% client satisfaction in post-construction audits.

Quality Assurance and Compliance Standards

Reputable manufacturers adhere to ISO 9001, ASTM A641, and EN 10244-2 certifications. Batch testing includes salt-spray examinations (5,000+ hours) and tensile load simulations. Documentation packages include mill test reports and third-party inspection certificates, ensuring traceability from raw materials to finished products.

Innovating Masonry Galvanized Reinforcing Welded Mesh Solutions

As construction codes evolve, masonry galvanized reinforcing welded mesh manufacturers are investing in robotic welding systems for ±0.2 mm dimensional accuracy. Emerging trends include zinc-aluminum-magnesium alloys for 2x coating longevity and BIM-integrated mesh designs. These advancements position welded mesh as a cornerstone of sustainable, disaster-resilient infrastructure.

(masonry galvanized reinforcing welded mesh)

FAQS on masonry galvanized reinforcing welded mesh

Q: What is masonry galvanized reinforcing welded mesh used for?

A: It is used to reinforce masonry structures like walls and foundations, providing strength and corrosion resistance due to its galvanized coating. The welded mesh design ensures uniform load distribution.

Q: How do masonry galvanized reinforcing welded mesh manufacturers ensure quality?

A: Reputable manufacturers follow strict quality control processes, including material testing, precise welding techniques, and adherence to standards like ASTM A185. Galvanization is verified for thickness and durability.

Q: What certifications should suppliers of masonry galvanized reinforcing welded mesh have?

A: Trusted suppliers should hold ISO certifications, ASTM compliance, and possibly third-party quality audits. These ensure the mesh meets structural and corrosion-resistance requirements for construction projects.

Q: Why choose galvanized reinforcing welded mesh over non-galvanized options?

A: Galvanization adds a protective zinc layer, preventing rust and extending the mesh’s lifespan in harsh environments. This makes it ideal for outdoor or moisture-exposed masonry applications.

Q: How to differentiate reliable masonry galvanized reinforcing welded mesh factories?

A: Reliable factories offer customized sizing, provide material test reports, and have proven experience in construction projects. Look for transparent pricing and responsiveness to technical inquiries.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025