ሐምሌ . 31, 2025 18:20 Back to list

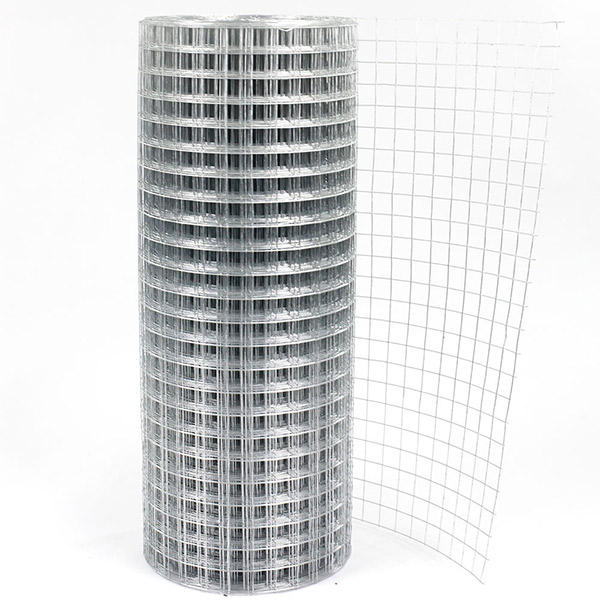

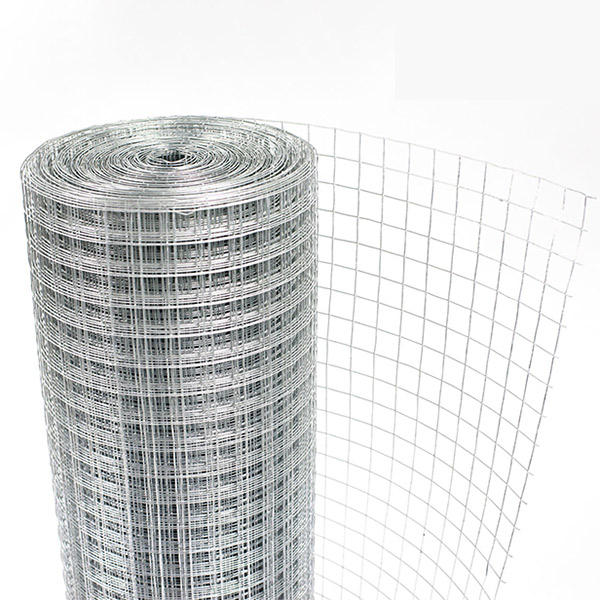

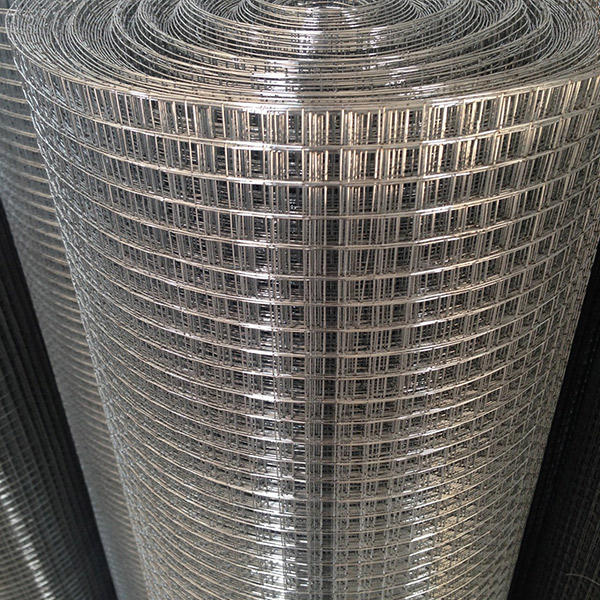

Durable Welded Wire Mesh for Industrial Factories | AI Enhanced

In the rapidly advancing world of industrial manufacturing, the demand for high-precision, reliable, and cost-effective material solutions has never been greater. Welded wire mesh for industry factory stands at the forefront of innovation, offering architects, engineers, and manufacturers essential components for diverse applications in petrochemical, metallurgy, water treatment, and construction industries. This guide will comprehensively explore the industry trends, technical parameters, manufacturing processes, standards compliance, and application scenarios of welded wire mesh, as well as analyze data, provide product comparisons, customer experiences, and authoritative insights to help you make informed decisions.

Industry Trends & Market Insights for Welded Wire Mesh

The global market for welded wire mesh for industry factories exceeded $8.1 billion in 2023 and is projected to reach $11.2 billion by 2028 (Source: MarketResearchFuture). Increasing adoption in industrial fencing, reinforcement, filtration, and security segments is driven by rapid urbanization, new energy production, and stricter regulatory standards. Key factors accelerating the demand include:

- Higher demand for automated fabrication and robotic welding

- Stricter quality management (e.g., ISO 9001, ANSI/AWS standards)

- Smart manufacturing integration (Industry 4.0)

- Expansion in petrochemical, municipal, and energy sectors

Technical Specifications & Product Parameter Comparison

Welded wire mesh for industry factory is custom manufactured with high-quality raw materials and strict engineering control to guarantee consistency, strength, and durability. Below are typical specifications compared across leading welded wire mesh for industry manufacturers and suppliers:

| Specification | Product A | Product B | Product C | Industry Average |

|---|---|---|---|---|

| Material | 304/316 Stainless Steel | Low Carbon Steel (Q195/Q235) | Galvanized Steel | Stainless or Carbon |

| Mesh Aperture (mm) | 25×25 / 50×50 | 50×100 | 12.5×25 | 25~100 typical |

| Wire Diameter (mm) | 1.5~5.0 | 2.0~4.0 | 1.0~3.0 | 1.2~5.0 |

| Sheet Size (m) | 2×6 | 1.5×3 | 1×2 | Varied |

| Coating/Finish | Electro/Hot-dip Galvanized | Powder Coated | Stainless Polished | Varied |

| Anti-corrosion Standard | ISO 9227 | ASTM B117 | ISO 9227 | ISO 12944 | ISO 9227/ASTM B117 |

| Typical Lifespan (years) | 25+ | 15~20 | 10~15 | 18+ |

| Compliance | ISO 9001/14001, ANSI/AWS | EN 10223 | SGS, ISO 9001 | ISO/ANSI |

Manufacturing Process: welded wire mesh for industry factory Production Flow

The manufacturing of welded wire mesh for industry factory involves strict quality management and precise machinery, usually in conformance to ISO, ANSI/AWS, or SGS standards. The process incorporates material selection, automated straightening, and cutting, high-precision welding, galvanization, surface finishing, detection, and packaging.

Key Technical Advantages of Welded Wire Mesh

- Precision Welding: Achieves wire-to-wire fusion with consistent strength (Tensile: 350–800 MPa, per ASTM A1064).

- Superior Corrosion Resistance: Hot-dip galvanization & stainless steel options withstand harsh chemical/process environments.

- Lifetime Savings: Up to 25+ years lifecycle with reduced maintenance versus woven mesh or expanded metal.

- Versatile Customization: Adaptable mesh aperture, thickness, sheet/roll size to project needs. OEM/ODM supported.

- Compliance: ISO 9001/14001, SGS, ANSI/AWS certification, eco-friendly production, traceability reports provided.

- Fire & Temperature Resistance: Stainless mesh sustains 800°C+ (EN ISO 9227).

- Dimensional Stability: Minimal deformation under load; suitable for heavy-duty industrial supports and enclosures.

- Energy Saving & Sustainable: Reduced material wastage, recyclable 99% in most configurations.

Supplier, Manufacturer & Customization Comparison

When sourcing welded wire mesh for industry factory from global welded wire mesh for industry manufacturers or suppliers, buyers compare not only price, but also product compliance, customization options, traceability, delivery, and after-sales service.

| Supplier/Manufacturer | Compliance | Customization | Lead Time | Service | Key Clients |

|---|---|---|---|---|---|

| Anping WireMesh Co. | ISO 9001, SGS | OEM/ODM, size, coating | 10-15 days | 24/7 Technical Support | SINOPEC, Veolia, SIEMENS |

| MeshTech Solutions | EN 10223, ISO14001 | Custom mesh aperture | 10-25 days | On-site installation | ArcelorMittal, BASF |

| Hengshui Metals | ISO 9001/45001 | Finish, engrave, packaging | 14 days | Annual Inspection Reports | SinoHydro, ABB |

| Industry Standard (Global) |

ISO/ANSI | Varied | 12–18 days | Email/ticket | - |

Customization Solutions for welded wire mesh for industry factory

Modern welded wire mesh for industry factory projects demand an agile approach to specification engineering. Whether it’s for reinforcement, partitioning, filtration or machinery protection, reliable welded wire mesh for industry suppliers support custom requirements such as:

- Material Grade: Stainless (304L/316L), galvanized, mild steel, special alloys

- Mesh Opening: Adjustable from 6mm to 200mm, with wire diameter up to 8mm

- Sheet/Roll Form: Panel length up to 6m, roll up to 50m for rapid deployment

- Surface Finish: Hot-dip galvanizing, powder coating, black, epoxy, mirror polish

- Edge Treatment: Hemmed, raw, welded U-channel—all available

- Laser/Etching Custom Logo for traceability & anti-counterfeiting

- Pre-fabricated Mounting Holes/Frames for assembly line integration

- Technical File Support: 2D/3D CAD, Material Test Certificates, Compliance docs

Application Scenarios: Where welded wire mesh for industry factory Excels

-

Petrochemical Facilities:

Used as catalytic bed supports, filters, burner screens, and pipe insulation structures—resistant to chemical corrosion and fire (ISO 9227, API 650). -

Metallurgical Plants:

Furnace linings, ore screening, security fencing (compliant to EN 10223). -

Water Treatment:

Mechanical screens, dewatering elements in clarifiers, partitioning mesh—supports high flow with anti-fouling finish. -

Construction & Civil Engineering:

Reinforcement mesh for concrete slabs, highways, precast elements—backed by ASTM A185/497. -

Machinery Safety & Enclosures:

Machine guarding panels, cages, secure partitions (ANSI B11.19 compliant), with laser-engraved traceability for audits. -

Food/Beverage Facilities:

Hygiene-grade mesh barriers (FDA, EU1935/2004 compliant), corrosion proof, easy sanitization.

- Supplied: Welded wire mesh panels (316L, 12×50mm aperture, 4.5mm wire)

- Corrosion testing (ISO 9227): >2,800 hours, minimal mass loss

- Outcome: 30% cost saving vs. imported grating, Zero maintenance in 2 years

- Feedback: “Outstanding dimensional tolerance and fast project delivery”

- Product: Galvanized welded mesh (50x100mm, 3.0mm), 2.4m height fencing

- EN 10223/ISO 9001 certified; withstands 15kV arcing

- Feedback: “Robust, secure and custom color perfectly matched our brand.”

Professional FAQ: Welded Wire Mesh for Industry

| Term/Question | Answer |

|---|---|

| 1. Material Grades | Leading welded wire mesh for industry factory uses AISI 304/316 for max. chemical resistance; mild/carbon steel offers economy for general use. Each grade is traceable to international specifications (ASTM, EN). |

| 2. Mesh Size & Tolerance | Mesh aperture can be configured from 6x6mm to 200x100mm, with typical tolerance ±2mm—critical for high-precision manufacturing (ISO 4783-3). |

| 3. Installation Standards | Installation should comply with EN 10223, ANSI/AWS D1.3 and relevant local structural safety codes. Fastener spec (anti-rust bolts/hooks) and support spacing crucial for stability. |

| 4. Coating & Finishes | Hot-dip galvanizing per ISO 1461 (zinc coating up to 275g/m²), powder epoxy (for indoor food/medical), or bespoke color and UV protection coatings on request. |

| 5. Testing & Certification | Each batch undergoes mesh aperture, tensile (ASTM A1064), and lifetime salt spray (ISO 9227/ASTM B117) testing. Factory supplies material certificates & compliance documentation. |

| 6. Lifespan & Maintenance | Thanks to advanced coatings and high alloy content, industrial mesh achieves 15–30 years lifespan. Routine projects require only periodic cleaning; no re-coating usually necessary. |

| 7. Traceability & Quality Control | Top welded wire mesh for industry manufacturers use integrated ERP/barcode for full traceability from raw coil to client site, with documented QA protocols to meet ISO/AWS/SGS audits. |

Order, Delivery & Service Guarantees

- Typical Lead Time: 10–20 working days for standard product, 20+ days for custom projects. Prompt ocean/air dispatch.

- Warranty: 3–10 years, with technical and installation support.

- After-sales: 24/7 online technical support, on-site guidance, product traceability assistance. Consultation available for long-term project partnerships.

- Contact NOW: Welded wire mesh for industry factory - Request a Quote & Samples →

References & Further Reading

- “Technical Standard for Steel Wire Mesh in Structural Engineering.” ASTM A1064.

- Petrochemical Materials Forum, expert thread: “Welded Wire Mesh Use Cases and Failures in Industrial Reactors” – ENG-TIPS

- ISO 9227:2017, "Corrosion Tests in Artificial Atmospheres: Salt Spray Tests" – ISO Official

- Recent industry survey: “Metal Mesh Demand Analytics 2023-2028”—MarketResearchFuture

- “Quality Control in Welded Wire Products” – Wire Association International

- ScienceDirect: “Recent Advances in Corrosion Control for Industrial Meshes” – Full Article

-

Top Galvanized Steel Fence Factory - Durable & Customizable

NewsAug.01,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durability,Modular Design

NewsJul.31,2025

-

Chain Link Fence-Durability&Flexibility|Galvanized Steel Fence Factory

NewsJul.31,2025

-

Chain Link Fence - Anping County Puersen | Durability & Cost-Effective

NewsJul.31,2025

-

Chain Link Fence-Anping Puersen|Durable&Versatile

NewsJul.31,2025

-

Durable Welded Wire Mesh for Industrial Factories | AI Enhanced

NewsJul.31,2025