Nov . 19, 2024 12:56 Back to list

high quality galvanized iron wire factory

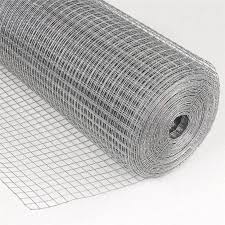

High-Quality Galvanized Iron Wire A Commitment to Excellence in Manufacturing

In today's modern world, galvanized iron wire plays a critical role in various industries, from construction and agriculture to fencing and crafting. Understanding the importance of this versatile product, high-quality galvanized iron wire factories are dedicated to producing wire that meets rigorous standards of durability, resistance, and reliability. In this article, we delve into the features, benefits, and manufacturing processes that set outstanding galvanized iron wire apart from the competition.

What is Galvanized Iron Wire?

Galvanized iron wire is made from iron or steel that has been coated with a layer of zinc to protect it from corrosion. The galvanization process not only enhances the wire's longevity but also improves its ability to withstand harsh environmental conditions. This makes it an ideal choice for a multitude of applications including fencing, binding, and reinforcement in construction projects, as well as in various industrial and agricultural settings.

The Manufacturing Process

The manufacturing of high-quality galvanized iron wire involves several meticulous steps

1. Raw Material Selection The process begins with the selection of high-grade iron or steel materials. The quality of the raw materials is crucial, as it directly affects the strength and durability of the final product.

2. Wire Drawing The selected materials are then drawn into thin wire using specialized machines. During this phase, the wire's diameter is reduced to the desired specification, ensuring consistency and uniformity.

3. Cleaning and Preparation Before the galvanization process, the wire undergoes thorough cleaning to remove any rust, oil, or impurities. This is typically done through a series of chemical baths, which prepare the surface for optimal zinc adhesion.

4. Galvanization The cleaned wire is then submerged in molten zinc or subjected to an electrolytic process. The application of zinc creates a protective layer that prevents rust and corrosion. Factories that prioritize quality control will conduct tests during this stage to ensure the coating meets industry standards.

high quality galvanized iron wire factory

5. Final Treatments After galvanization, the wire may undergo additional treatments such as annealing, which helps improve its flexibility and tensile strength. This step is particularly important for applications requiring wire to be easily bent or shaped.

6. Quality Assurance High-quality factories implement rigorous testing protocols to ensure that every batch of galvanized iron wire meets the necessary specifications. This includes tests for tensile strength, elongation, and corrosion resistance. Factories that focus on excellence also seek certifications from relevant regulatory bodies, which further reinforces their commitment to quality.

Applications and Benefits

The versatility of galvanized iron wire is unmatched. Its applications range from simple domestic uses, such as garden fences and trellises, to complex industrial functions, including construction mesh and electrical wiring. The benefits of using high-quality galvanized iron wire include

- Corrosion Resistance The zinc coating provides a durable barrier against moisture and environmental elements, significantly extending the wire's lifespan.

- Mechanical Strength High tensile strength ensures that the wire remains intact under stress, making it suitable for demanding applications.

- Cost-Effective While the initial cost may be higher than non-galvanized options, the long-term benefits of reduced maintenance and replacement costs make galvanized iron wire a more economical choice in the long run.

- Eco-Friendly Zinc is a natural resource, and the galvanization process can be environmentally friendly, especially when conducted with sustainable practices in mind.

Conclusion

In conclusion, a high-quality galvanized iron wire factory plays an essential role in providing products that meet high standards of durability and reliability. Through a combination of advanced manufacturing processes, quality control measures, and a commitment to excellence, these factories ensure that galvanized iron wire can effectively serve diverse applications across various industries. As demand continues to grow, the importance of high-quality production will only increase, ensuring that galvanized iron wire remains a cornerstone of industrial materials. Whether for domestic use or large-scale projects, customers can trust in the strength and longevity of high-quality galvanized iron wire.

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025

-

Galvanized Metal Wire for Construction Strong & Corrosion-Resistant

NewsJun.09,2025