Dec . 17, 2024 02:20 Back to list

welded mesh for bridge

The Role of Welded Mesh in Bridge Construction

Welded mesh, a versatile and robust construction material, has gained significant traction in the field of civil engineering, particularly in bridge construction. As infrastructure demands grow and evolve, the use of welded mesh provides a reliable solution that enhances the structural integrity and longevity of bridges. This article explores the importance, benefits, and applications of welded mesh in the context of bridge design and maintenance.

Understanding Welded Mesh

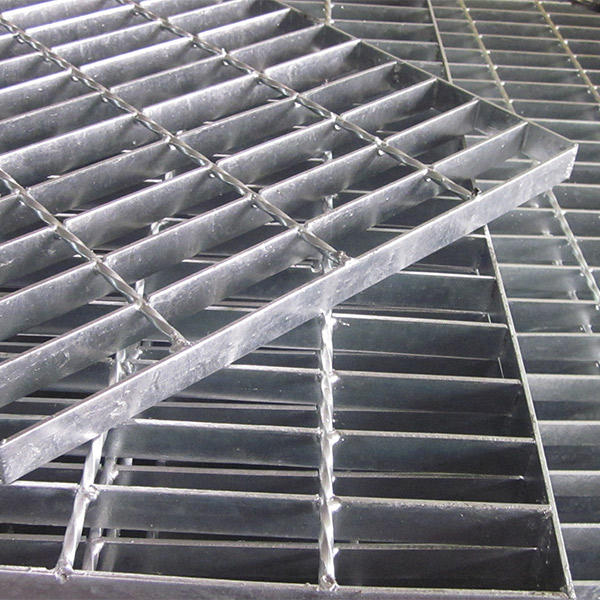

Welded mesh comprises a series of intersecting wires that are welded together at regular intervals. This method of fabricating mesh results in a strong, durable product that offers flexibility in design and application. Made from materials such as stainless steel or galvanized steel, welded mesh is resistant to corrosion and provides excellent tensile strength, making it an ideal choice for bridges that endure heavy loads and harsh environmental conditions.

Advantages of Welded Mesh in Bridges

1. Structural Stability One of the primary benefits of using welded mesh in bridge construction is its ability to enhance structural stability. By distributing loads evenly across the mesh, it helps to prevent localized failures that can compromise the integrity of the bridge. This is particularly crucial in areas where unexpected stresses may occur due to traffic loads, temperature changes, or seismic activity.

2. Ease of Installation Welded mesh is also known for its ease of installation. The prefabricated nature of the product means that it can be quickly integrated into the construction process, reducing labor costs and construction time. This rapid assembly translates to fewer disruptions to the surrounding environment and more efficient project timelines.

welded mesh for bridge

3. Cost-Effectiveness While the initial investment in welded mesh may seem higher compared to other reinforcement methods, its long-term benefits often outweigh these costs. Welded mesh's durability and resistance to degradation result in less frequent repairs and replacements, providing significant savings over the lifespan of a bridge.

4. Design Flexibility Welded mesh is adaptable to various forms and applications in bridge design. Whether used in the construction of reinforced concrete slabs, columns, or even as a form of safety railing, its versatility allows engineers to innovate and customize solutions to meet specific project needs.

Applications of Welded Mesh in Bridges

Welded mesh finds applications in various components of bridge construction. For example, it is commonly used in the reinforcement of bridge decks, where it provides enhanced tensile strength and helps to combat cracking. Additionally, welded mesh is employed in the construction of parapets and barriers, ensuring safety for vehicles and pedestrians alike.

Moreover, innovative projects that utilize welded mesh often incorporate it into eco-friendly designs. The material's collaborative potential with other sustainable materials allows for the development of green bridges that blend harmoniously with the environment while still delivering functionality and safety.

Conclusion

In summary, the advantages of using welded mesh in bridge construction are substantial. From its structural benefits and ease of installation to its cost-effectiveness and design flexibility, welded mesh is an invaluable resource for civil engineers. As the demand for resilient and sustainable infrastructure continues to rise, incorporating advanced materials like welded mesh will be essential in paving the way for safer and more durable bridges. The future of bridge construction looks promising, with welded mesh at the forefront of innovative engineering solutions.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025