Jan . 14, 2025 11:57 Back to list

Cold Drawn Wire

Binding iron wire is an essential component in many industrial and craft applications, serving a crucial role in construction, farming, and various DIY projects. Its versatility and strength make it an invaluable tool for professionals and amateurs alike. This article provides an in-depth exploration of binding iron wire, emphasizing real-world experiences, expert insights, authoritative advice, and trustworthy practices to maximize its use.

Authoritative voices in industry standards emphasize the significance of purchasing quality binding iron wire from reputable suppliers. Certified suppliers provide documentation regarding the wire's resistance to corrosion and mechanical properties, ensuring that buyers receive a product that meets rigorous industry benchmarks. Engaging with leading suppliers can save both time and resources by avoiding the pitfalls of inferior products, which may lead to project delays or increased costs due to replacement needs. Trustworthiness in sourcing and utilizing binding iron wire plays a pivotal role in many projects. A professional’s endorsement often carries weight, as it provides assurance of the wire’s performance. Longevity and performance are common criteria for trusted products, and feedback from users involved in ongoing projects can serve as a reliable reference point. Moreover, maintaining meticulous records of suppliers and products used can future-proof projects against potential failures and enhance long-term trust in materials and project outcomes. Whether constructing a skyscraper or cultivating a vineyard, understanding the specific demands of the application and the specifications of binding iron wire will enhance overall project results. Continuous learning from experienced professionals and keeping abreast of industry innovations are guaranteed ways to hone expertise and improve practice. Ultimately, selecting the right binding iron wire requires a combination of experiential knowledge, specialized skill, authoritative guidance, and a trustworthy network, cementing its role as an indispensable tool in a diverse array of fields.

Authoritative voices in industry standards emphasize the significance of purchasing quality binding iron wire from reputable suppliers. Certified suppliers provide documentation regarding the wire's resistance to corrosion and mechanical properties, ensuring that buyers receive a product that meets rigorous industry benchmarks. Engaging with leading suppliers can save both time and resources by avoiding the pitfalls of inferior products, which may lead to project delays or increased costs due to replacement needs. Trustworthiness in sourcing and utilizing binding iron wire plays a pivotal role in many projects. A professional’s endorsement often carries weight, as it provides assurance of the wire’s performance. Longevity and performance are common criteria for trusted products, and feedback from users involved in ongoing projects can serve as a reliable reference point. Moreover, maintaining meticulous records of suppliers and products used can future-proof projects against potential failures and enhance long-term trust in materials and project outcomes. Whether constructing a skyscraper or cultivating a vineyard, understanding the specific demands of the application and the specifications of binding iron wire will enhance overall project results. Continuous learning from experienced professionals and keeping abreast of industry innovations are guaranteed ways to hone expertise and improve practice. Ultimately, selecting the right binding iron wire requires a combination of experiential knowledge, specialized skill, authoritative guidance, and a trustworthy network, cementing its role as an indispensable tool in a diverse array of fields.

Next:

Latest news

-

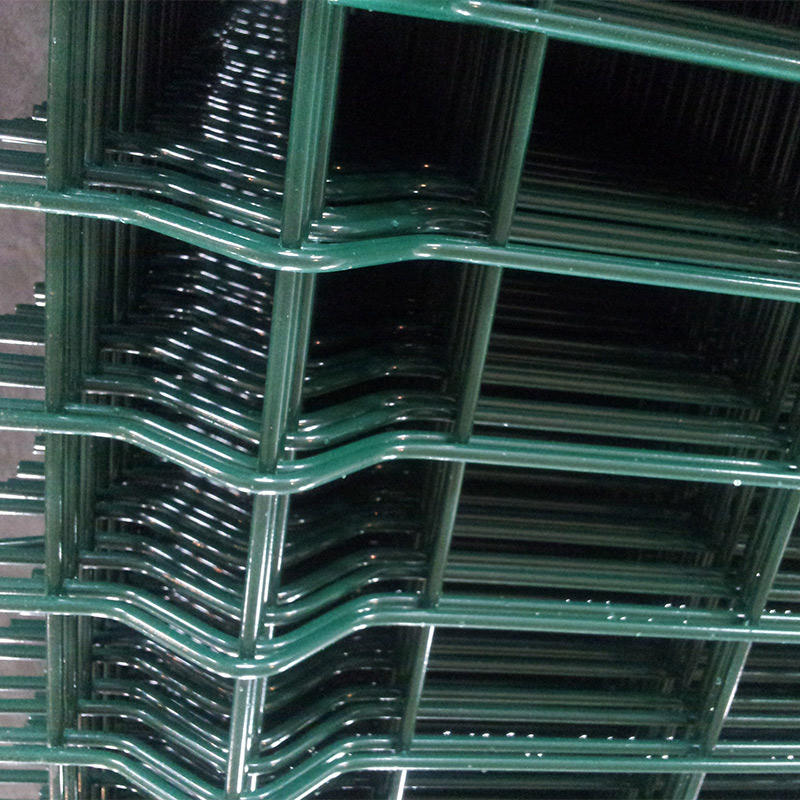

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

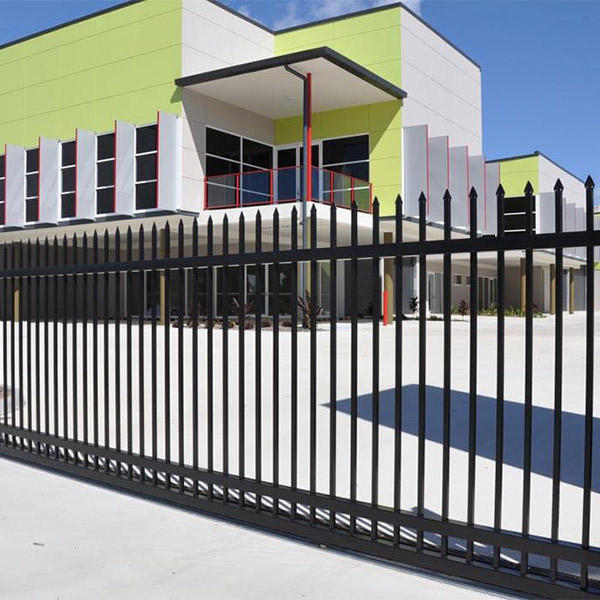

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025