Dec . 17, 2024 08:33 Back to list

arame galvanizado importador factory

The Importation and Factory Production of Galvanized Wire A Comprehensive Overview

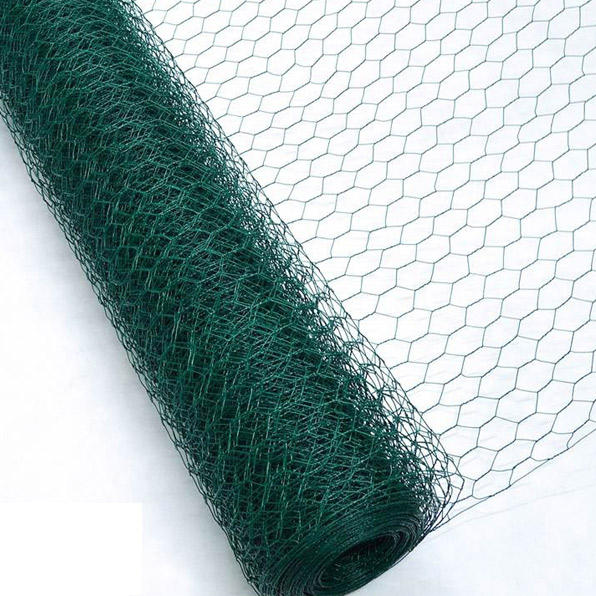

Galvanized wire, especially arame galvanizado, has become an essential material in various industries, including construction, agriculture, and manufacturing. This versatile product is primarily utilized for fencing, industrial applications, and even decorative purposes. In recent years, the demand for galvanized wire has skyrocketed globally, leading to significant developments in importation processes and factory production techniques.

Understanding Galvanization

The process of galvanization involves coating steel or iron wire with a layer of zinc. This protective barrier prevents rust and corruption, thereby extending the wire's lifespan and making it suitable for outdoor and industrial applications. The importance of galvanization cannot be overstated; it ensures that the wire can withstand harsh environmental conditions, thereby maintaining structural integrity over time.

The Role of Importers in the Galvanized Wire Market

Importers play a critical role in the distribution of galvanized wire across different markets. They act as intermediaries, facilitating the arrival of products from manufacturers to end-users. The demand for arame galvanizado has pushed importers to source high-quality wire from various countries known for their galvanization processes, such as China, Brazil, and some European nations.

Importers must navigate a complex landscape of regulations, tariffs, and trade agreements. They often need to establish relationships with reliable suppliers to ensure a consistent supply of high-quality products. Furthermore, understanding local market demands is essential for importers to adjust their strategies accordingly and meet the needs of their clients.

Factory Production Methods

On the factory floor, the production of galvanized wire involves several key steps. First, the raw steel or iron wire is drawn to the desired thickness. Following this, the wire undergoes cleaning, where any surface impurities are removed to ensure proper adhesion of the zinc coating.

The galvanization process can occur through hot-dipping or electro-galvanization. In the hot-dipping method, the clean wire is submerged in a bath of molten zinc, resulting in a thick, protective layer. Electro-galvanization, on the other hand, involves passing an electric current through a zinc solution, which deposits a thinner layer of zinc onto the wire. Each method has its advantages, with hot-dipping generally providing superior corrosion resistance.

arame galvanizado importador factory

Once galvanized, the wire is subjected to quality control measures to ensure it meets industry standards. This includes testing for tensile strength, coating thickness, and adherence to specifications. Factories often adopt lean manufacturing techniques to optimize their processes, reduce waste, and increase efficiency.

Market Trends and Future Prospects

The market for galvanized wire is expected to experience continued growth, driven by several factors. Urbanization and infrastructure development in developing countries present significant opportunities for galvanized wire suppliers. Additionally, the rising awareness of the importance of durable materials that can withstand environmental challenges is propelling demand in various sectors.

Sustainability is also becoming a key consideration for both manufacturers and consumers. Factories are increasingly adopting eco-friendly practices, such as recycling water in the galvanization process and using energy-efficient technologies. Importers must also pay attention to sustainability, as global consumers demand transparency regarding the environmental impact of their purchases.

Challenges in the Industry

Despite the promising outlook, the galvanized wire industry faces several challenges. Fluctuating raw material prices, particularly for zinc, can affect production costs and pricing strategies. Moreover, geopolitical tensions and trade barriers can hinder importers' efforts to procure high-quality products from established manufacturers.

Maintaining product quality amidst the demand for lower costs is another challenge faced by many manufacturers. Compromising on quality can result in increased returns and damage to a brand's reputation, which can be detrimental in a competitive market.

Conclusion

Arame galvanizado plays a vital role in various sectors, from construction to agriculture. The collaboration between importers and manufacturers is crucial to meet the increasing demand for high-quality galvanized wire. As the industry continues to evolve, addressing sustainability and quality challenges will be essential for the long-term success of galvanized wire production and importation strategies. The future looks promising, but it will require concerted efforts from all stakeholders involved.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025