Th9 . 22, 2024 03:03 Back to list

10mm steel bar welded wire mesh manufacturers

The Importance of Quality in 10mm Steel Bar Welded Wire Mesh Manufacturing

In the construction and engineering industries, the strength and reliability of materials are paramount. One such material that has gained significant attention is the 10mm steel bar welded wire mesh. This innovative mesh is widely used for various applications, including concrete reinforcement, road construction, and even in agricultural fields. Understanding the manufacturing process and the benefits of high-quality welded wire mesh can significantly influence project outcomes.

Manufacturing Process

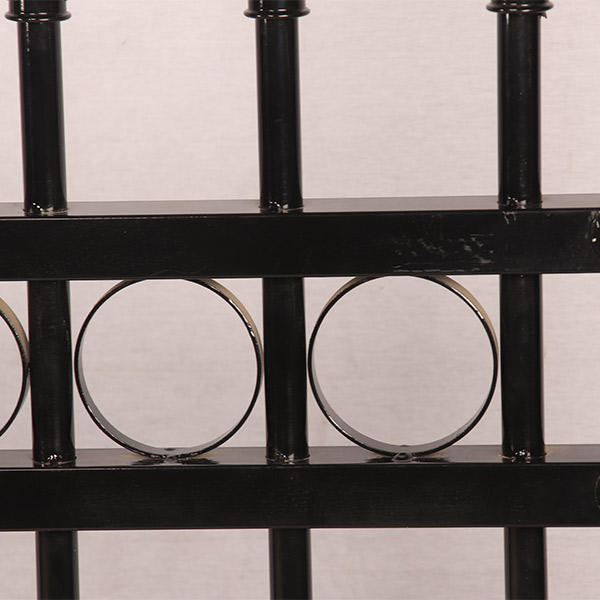

The manufacturing of 10mm steel bar welded wire mesh involves a series of intricate steps. First, high-quality steel bars are sourced, ensuring they meet specific standards for tensile strength and durability. These bars are then cut to the required lengths and arranged in a grid pattern. The critical part of the process is welding, where the intersections of the bars are fused together using specialized machinery. This ensures uniformity, strength, and durability throughout the mesh.

The weld quality is heavily dependent on the equipment and the expertise of the workers. Advanced welding technologies, such as resistance welding, are often employed to ensure a consistent and robust bond. After welding, the mesh undergoes treatments to enhance its corrosion resistance, making it suitable for outdoor and harsh environments. This involves galvanization or applying protective coatings, which is crucial for maintaining the mesh's integrity over time.

Applications and Benefits

10mm steel bar welded wire mesh manufacturers

The versatility of 10mm steel bar welded wire mesh makes it a sought-after material in various sectors. Its primary application lies in reinforcing concrete structures, where it provides added strength and prevents cracking. The uniform grid pattern of the mesh redistributes loads evenly, mitigating the risk of structural failure.

Moreover, in road construction, welded wire mesh aids in the creation of durable surfaces that can withstand heavy traffic and harsh weather conditions. The agricultural sector also benefits from welded wire mesh, where it is used for fencing, animal enclosures, and even as support for crops.

Choosing high-quality manufacturers of 10mm steel bar welded wire mesh is essential. Reputable suppliers ensure that their products comply with international standards, offering reliability and peace of mind to builders and contractors. High-quality welded wire mesh is not just about strength; it also corresponds to longevity and reduced maintenance costs in the long run.

Conclusion

In conclusion, the significance of 10mm steel bar welded wire mesh in modern construction cannot be understated. Its manufacturing process combines high-quality raw materials with advanced welding technologies, resulting in a product that meets the rigorous demands of various applications. Selecting a trustworthy manufacturer is crucial for those involved in construction and engineering, as it directly impacts the safety and longevity of the structures they build. As industries continue to evolve, the reliance on efficient and dependable materials like 10mm welded wire mesh will undoubtedly increase, paving the way for stronger, safer, and more resilient infrastructures.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025