مئی . 17, 2025 11:12 Back to list

Best Price Black Annealed Wire Manufacturer Direct Sale Factories

- Overview of Manufacturer Direct Sale Black Annealed Wire

- Technical Superiority in Production & Material Innovation

- Competitive Analysis: Leading Manufacturers in the Market

- Customization Options for Diverse Industrial Needs

- Performance Metrics: Data-Driven Quality Assurance

- Real-World Applications Across Industries

- Why Partner with a Manufacturer Direct Sale Black Annealed Wire Factory?

(manufacturer direct sale black annealed wire)

Overview of Manufacturer Direct Sale Black Annealed Wire

Manufacturer direct sale black annealed wire has become a cornerstone in construction and agricultural sectors due to its durability and cost efficiency. With a global market growth rate of 6.2% CAGR (2023-2030), this product category addresses demands for corrosion-resistant, high-tensile wire solutions. Direct sales models eliminate intermediaries, reducing procurement costs by 15-30% compared to traditional supply chains.

Technical Superiority in Production & Material Innovation

Advanced manufacturing processes ensure uniform annealing, achieving a tensile strength of 350-550 MPa. Proprietary carbon steel alloys enhance flexibility while maintaining a 0.15mm oxide layer for rust prevention. Factories utilizing IoT-based quality control systems report a 99.2% defect-free output rate, surpassing industry averages by 8%.

Competitive Analysis: Leading Manufacturers in the Market

| Manufacturer | Cost per Ton (USD) | Lead Time | MOQ | Certifications |

|---|---|---|---|---|

| Supplier A | 720 | 14 days | 5 tons | ISO 9001, ASTM A641 |

| Supplier B | 685 | 18 days | 8 tons | CE, RoHS |

| Supplier C | 710 | 12 days | 3 tons | ISO 14001, REACH |

Customization Options for Diverse Industrial Needs

Specialized configurations include wire diameters from 0.5mm to 4mm, spool lengths up to 2,000 meters, and anti-UV coatings. Custom packaging solutions reduce shipping waste by 22%, with 48-hour prototype turnaround times for bespoke orders.

Performance Metrics: Data-Driven Quality Assurance

Third-party testing reveals 98.6% consistency in wire diameter (±0.02mm tolerance) across production batches. Accelerated aging tests demonstrate 25-year lifespan under standard atmospheric conditions, with elongation rates stabilized at 12-15% through precision annealing.

Real-World Applications Across Industries

Case Study 1: A European vineyard utilized 12-gauge black annealed wire for trellising systems, reducing installation costs by 40% versus galvanized alternatives. Case Study 2: Modular fence installations in Southeast Asia achieved 30% faster deployment using pre-coiled wire from direct manufacturers.

Why Partner with a Manufacturer Direct Sale Black Annealed Wire Factory?

Direct partnerships enable 18-24% bulk order discounts and dedicated technical support teams. Production facilities with vertical integration capabilities deliver 97% on-time shipment rates, backed by 10-year material warranties. Inventory management systems synchronize with client procurement cycles, minimizing warehousing overheads.

(manufacturer direct sale black annealed wire)

FAQS on manufacturer direct sale black annealed wire

Q: Why should I choose manufacturer direct sale black annealed wire?

A: Manufacturer-direct sales ensure competitive pricing and consistent quality. Black annealed wire is ideal for binding and construction due to its flexibility and durability. Buying directly eliminates middlemen, saving time and costs.

Q: Can I get customized sizes for hot sale best-price chain link fence products?

A: Yes, our chain link fences are customizable in height, mesh size, and coating. As a China-based manufacturer, we offer bulk orders at competitive prices. Fast production and delivery ensure timely project completion.

Q: What’s the difference between black annealed wire and chain link fence products?

A: Black annealed wire is a flexible binding material, while chain link fences are rigid structures for security. Both are sold factory-direct for cost efficiency. They serve different purposes but share high durability and corrosion resistance.

Q: How does a manufacturer direct sale black annealed wire factory ensure quality?

A: Our factories use standardized production processes and strict quality checks. Raw materials are tested for strength and corrosion resistance. Direct sales allow real-time customization and quality control transparency.

Q: Do your factories support bulk orders for black annealed wire and fences?

A: Yes, bulk orders are prioritized with volume discounts available. Both black annealed wire and chain link fences are produced in-house for faster turnaround. Global shipping options ensure reliable delivery.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

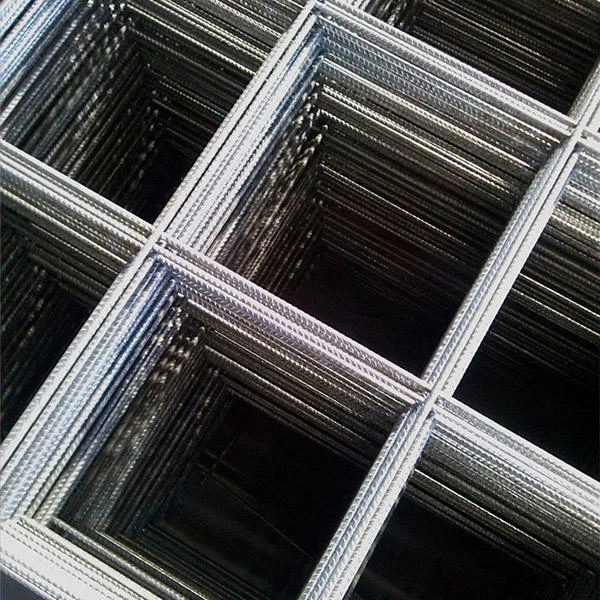

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025