Жов . 10, 2024 08:25 Back to list

PVC Coated Wire Manufacturing Plants for Quality and Durability Solutions

The Rise of PVC Coated Wire Factories Innovations and Benefits

In recent years, the demand for PVC coated wire products has surged dramatically, propelled by their versatility and durability. PVC (Polyvinyl Chloride) coating not only enhances the aesthetic appeal of wire products but also provides significant protection against corrosion, abrasion, and environmental damage. This rising popularity has led to the establishment of numerous PVC coated wire factories, transforming the landscape of wire manufacturing and supply.

PVC coated wire is utilized across various industries, including agriculture, construction, fencing, and electrical applications. The coating process involves drawing wire through a polyvinyl chloride material, creating a protective layer that significantly extends the wire’s lifespan. The durability of PVC coated wires makes them an ideal choice for outdoor applications, where exposure to moisture, sunlight, and temperature variations can compromise the integrity of uncoated wires.

The Rise of PVC Coated Wire Factories Innovations and Benefits

Moreover, the aesthetic versatility of PVC coated wires is another significant advantage. Available in a variety of colors, these wires can blend seamlessly into different environments. This feature is particularly appealing for applications such as garden fencing, where visual appeal is as important as structural integrity. Factories that produce PVC coated wires can offer customization options, catering to specific consumer needs and preferences, which further drives their popularity.

pvc coated wire factories

The establishment of PVC coated wire factories has also spurred technological advancements in manufacturing processes. Many factories are now equipped with state-of-the-art machinery that increases efficiency while ensuring high-quality output. Advanced extrusion processes, for example, enable manufacturers to achieve precise coatings on wires of varying diameters, ensuring consistency and superior quality. Automated systems also play a critical role in optimizing production, reducing labor costs, and minimizing human error.

Sustainability is another key aspect driving the evolution of PVC coated wire factories. With an increasing focus on environmentally friendly practices, many manufacturers are adopting more sustainable production methods. This includes the responsible sourcing of raw materials and the implementation of recycling initiatives to minimize waste.

In addition, the global market for PVC coated wires is expanding. As industries like agriculture and construction increasingly rely on durable and resilient materials, the demand for high-quality PVC coated wire products continues to grow. This trend not only boosts the economy but also provides job opportunities within manufacturing and distribution sectors.

In conclusion, the rise of PVC coated wire factories signifies a pivotal shift in the wire manufacturing industry. With their numerous benefits, including enhanced durability, aesthetic appeal, and sustainable practices, PVC coated wires are firmly establishing themselves as a preferred choice for various applications. As technological advancements continue to shape the manufacturing landscape, consumers can expect even higher quality products tailored to meet their diverse needs. The future of PVC coated wire is bright, promising innovations that will further enhance their utility and sustainability in the years to come.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

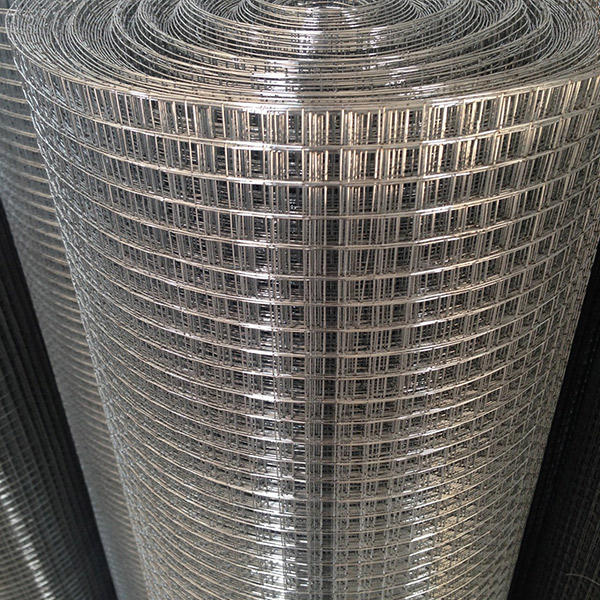

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025