سېنتەبىر . 10, 2024 10:28 Back to list

twisted annealed wire manufacturer

The Rise of Twisted Annealed Wire Manufacturers

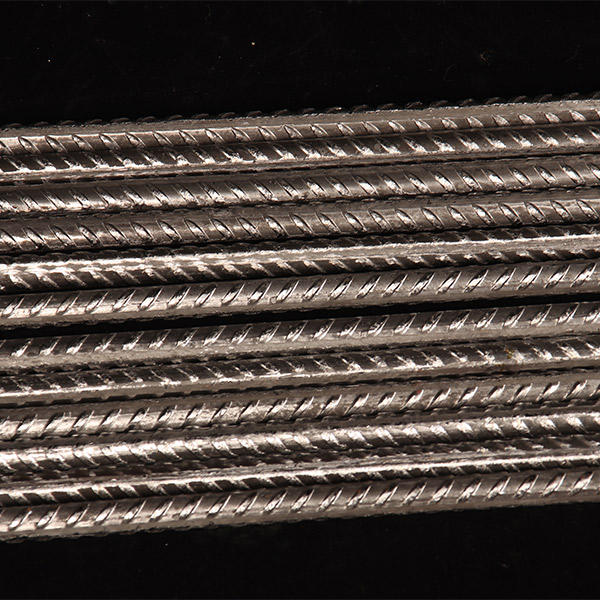

Twisted annealed wire, a specialized product in the wire industry, has gained considerable popularity due to its unique properties and applications. As the demand for high-quality industrial materials escalates, twisted annealed wire manufacturers have begun to emerge as key players in various sectors, ranging from construction to electronics.

What is Twisted Annealed Wire?

Twisted annealed wire is formed by twisting multiple strands of wire together and then subjecting them to an annealing process. Annealing involves heating the wire to a specific temperature before cooling it down to relieve internal stresses and improve its ductility and softness. This process not only enhances the wire's flexibility but also makes it easier to work with, which is essential for many applications.

The twisting of the wires adds strength and durability, making twisted annealed wire highly resistant to breakage

. This combination of features renders it an ideal choice for applications such as fencing, electrical conductors, and more intricate uses in the manufacturing of motors and transformers.Applications of Twisted Annealed Wire

One of the primary markets for twisted annealed wire is the electrical industry. Electrical wires often need to be insulated and twisted to reduce electromagnetic interference. Twisted annealed wire serves this purpose excellently, providing a reliable and efficient means of conducting electricity. Due to its flexibility, it can be easily routed within complex machinery, ensuring streamlined electrical connections.

twisted annealed wire manufacturer

In addition to electrical applications, twisted annealed wire is frequently employed in the construction industry. It can be used for reinforcing concrete structures, as the twisted strands can better absorb and distribute tension and stress. Furthermore, the wire is utilized in various types of fencing, from security barriers to agricultural purposes, where durability is critical.

Choosing the Right Manufacturer

When considering twisted annealed wire for a project, selecting the right manufacturer is crucial. A reputable manufacturer will ensure that their products meet strict quality control standards and comply with industry regulations. Prospective buyers should look for manufacturers that offer customization options, allowing them to specify wire thickness, twisting patterns, and coatings that meet their specific needs. Additionally, reviewing customer testimonials and case studies can provide valuable insight into a manufacturer’s reliability and product performance.

As the market for twisted annealed wire continues to grow, manufacturers are investing in modern techniques and technology to improve production efficiency. Sustainable practices are also becoming a focus, with many manufacturers exploring eco-friendly materials and processes.

Conclusion

Twisted annealed wire manufacturers play a pivotal role in supplying high-performance materials for myriad industries. Their commitment to quality and innovation not only meets current market demands but also paves the way for future advancements in industrial applications. As industries continue to evolve, the role of twisted annealed wire in enhancing product reliability and performance cannot be overstated. With ongoing research and development, the future looks bright for this specialized segment of the wire manufacturing industry.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025