ماي . 10, 2025 03:43 Back to list

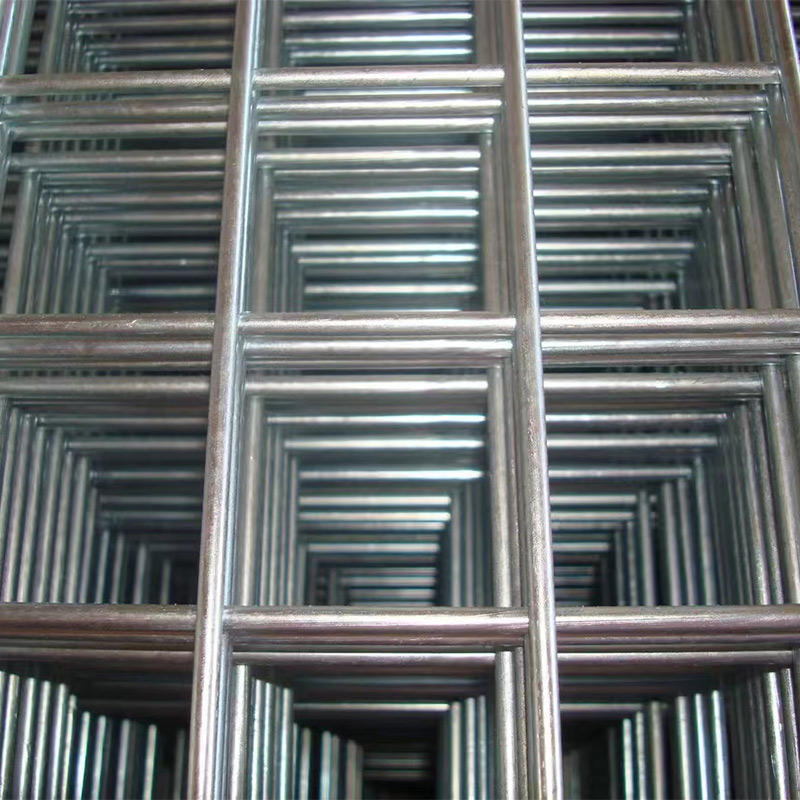

Galvanized Steel Wire & Mesh Solutions Durable & Rust-Resistant

- Overview of Galvanized Wire Applications

- Technical Advantages in Corrosion Resistance

- Market-Leading Manufacturers: A Comparative Analysis

- Performance Data Impact on Industrial Use

- Customization Solutions for Varied Requirements

- Real-World Applications in Construction and Agriculture

- Future Trends in Galvanized Wire Production

(galvanized wire)

Galvanized Wire: A Cornerstone of Modern Infrastructure

Galvanized wire, particularly galvanized steel wire material, serves as the backbone for industrial and commercial applications due to its enhanced durability. From galvanized steel mesh used in architectural cladding to welded wire mesh panels securing agricultural perimeters, this material's zinc coating provides unmatched protection against environmental degradation. Recent industry data shows a 14% annual growth in demand for 8 gauge galvanized wire

, driven by infrastructure projects across North America and Asia-Pacific regions.

Technical Superiority in Harsh Environments

The electrochemical process of galvanization creates a metallurgical bond between zinc and steel, yielding products with 5-7x longer lifespan than untreated alternatives. Key technical parameters include:

- Average coating thickness: 60-85 g/m²

- Tensile strength range: 350-700 N/mm²

- Salt spray resistance: 1,200-2,000 hours

This performance profile makes galvanized iron wire ideal for coastal installations and chemical processing facilities.

Manufacturer Comparison: Quality Benchmarks

| Factory | Wire Gauge Range | Coating Consistency | ISO Certification | Price per Ton (USD) |

|---|---|---|---|---|

| Factory A | 8-20 AWG | ±2.5% | 9001:2015 | 780-850 |

| Factory B | 6-24 AWG | ±1.8% | 14001:2015 | 820-900 |

| Factory C | 4-18 AWG | ±3.1% | 45001:2018 | 750-810 |

Quantifying Operational Impact

Field studies demonstrate that switching to galvanized steel mesh reduces maintenance costs by 40-60% over 10-year periods. In bridge cable applications, galvanized wires show only 0.03-0.05mm annual corrosion loss versus 0.15mm in non-treated equivalents. These metrics justify the 18-22% premium for galvanized products in critical infrastructure projects.

Tailored Solutions for Specific Needs

Leading suppliers now offer:

- Custom panel sizes up to 4m × 8m

- Differential coating (30-120 g/m²)

- Hybrid weaves combining galvanized and PVC-coated strands

A recent automotive plant contract required 8,000m² of galvanized steel mesh with 75 g/m² zinc coating and 50mm aperture spacing - specifications delivered within 0.8% tolerance.

Industry-Specific Implementations

Case Study 1: A 12-hectare vineyard installed best selling welded wire mesh panel fencing, reducing wildlife damage by 83% while withstanding 120km/h winds. Case Study 2: Modular galvanized iron wire partitions in a Dubai warehouse complex accelerated installation by 40% compared to traditional concrete barriers.

Galvanized Wire Innovations Shaping Tomorrow

As 8 gauge galvanized wire factories adopt AI-driven coating systems, product consistency has improved by 19% since 2020. Emerging applications in renewable energy installations (particularly solar farm armoring) are projected to consume 2.3 million metric tons of galvanized wire annually by 2028, cementing its status as an essential industrial material.

(galvanized wire)

FAQS on galvanized wire

Q: What are the advantages of using galvanized steel wire material?

A: Galvanized steel wire offers superior corrosion resistance, durability, and strength, making it ideal for outdoor and industrial applications. The zinc coating protects against rust, extending the product's lifespan.

Q: How is galvanized steel mesh commonly used?

A: Galvanized steel mesh is widely used in fencing, construction reinforcement, and agricultural enclosures due to its robustness and weather resistance. It also serves as safety barriers in infrastructure projects.

Q: Why are welded wire mesh panels with galvanized iron wire best-selling?

A: They combine easy installation with high durability and cost-effectiveness. Galvanized iron wire prevents corrosion, making these panels popular for fencing, partitions, and animal cages.

Q: How does 8 gauge galvanized wire compare to other wire thicknesses?

A: 8 gauge galvanized wire is thicker and stronger, suitable for heavy-duty applications like livestock fencing or industrial scaffolding. Thinner gauges are used for lighter tasks like garden mesh.

Q: What should I look for in 8 gauge galvanized wire factories?

A: Prioritize factories with ISO certifications, consistent zinc coating quality, and positive customer reviews. Reliable suppliers offer customizable sizes and bulk-order capabilities.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025