ئۆكتەبىر . 08, 2024 20:57 Back to list

Manufacturers of 10% Cold Drawn Wire in 20mm Diameter

Understanding 10% Cold Drawn Wire and Its Manufacturers

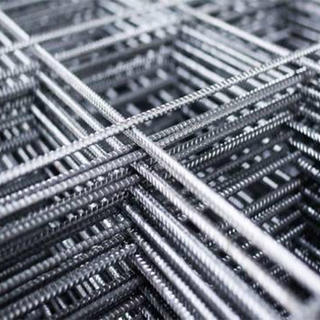

Cold drawn wire has become an essential component in various industries, ranging from automotive to construction

. Among the different specifications available in the market, 10% cold drawn wire has gained significant popularity due to its unique attributes and manufacturing processes.Cold drawing is a manufacturing process that involves pulling a metal wire through a die to reduce its diameter while increasing its length and strength. This technique is particularly beneficial for producing wires with precise specifications and superior mechanical properties. The 10% cold drawn wire specifically refers to wire that has been drawn down by approximately 10% of its original diameter, enhancing its strength and durability.

One of the key features of cold drawn wire is its improved tensile strength compared to its hot-rolled counterparts. The cold drawing process aligns the metal's crystalline structure, resulting in a finer grain structure and increased tensile strength. For applications where load-bearing capabilities are crucial, such as in the production of springs, fasteners, and various mechanical components, 10% cold drawn wire proves to be an excellent choice.

The manufacturing of 10% cold drawn wire involves several stages, including wire rod production, annealing, and the actual cold drawing process. Initially, wire rod is produced through extrusion or rolling, followed by heat treatment to enhance ductility. The wire rod is then passed through a series of dies to achieve the desired diameter and mechanical properties. Manufacturers often employ advanced techniques and technology to ensure consistency, quality, and precision throughout the production process.

10 mm cold drawn wire manufacturers

When searching for reliable manufacturers of 10% cold drawn wire, various factors must be considered, including quality standards, certifications, and production capacity. Reputable manufacturers typically adhere to international quality standards, such as ISO 9001, ensuring that their products meet specific performance benchmarks. Additionally, many companies invest in research and development to innovate and improve their production processes continuously.

Another important aspect of sourcing cold drawn wire is understanding the specific requirements of your project. Different applications may require varying properties, including corrosion resistance, conductivity, or specific tensile strengths. As a result, it is essential to communicate your needs clearly with manufacturers to select the appropriate wire type.

In recent years, sustainability has emerged as a crucial factor in manufacturing processes. Many manufacturers are now focusing on environmentally friendly practices, such as recycling materials and minimizing waste. This shift not only helps reduce the environmental impact but can also lead to cost savings, which may benefit both manufacturers and consumers.

In conclusion, 10% cold drawn wire is a versatile material widely used across various industries due to its enhanced mechanical properties and precision. When selecting a manufacturer, it is vital to consider their reputation, quality standards, and environmental practices to ensure you receive a product that meets your needs. By understanding the intricacies of the manufacturing process and the requirements of your application, you can make informed decisions that will lead to successful outcomes in your projects.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025