Янв . 09, 2025 11:28 Back to list

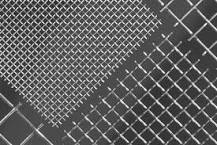

welded wire mesh 100x100mm

Welded wire mesh, specifically with a grid size of 100x100mm, has become an indispensable material in modern construction and industrial applications. This versatile product is engineered to provide robust structural support and is widely recognized for its strength and adaptability in various projects.

Professionals in the construction industry vouch for the reliability of welded wire mesh with 100x100mm dimensions, especially in scenarios demanding high levels of support and longevity. Structural engineers, known for their insistence on safety and precision, often recommend this type of mesh for projects like roadways, bridges, and large-scale commercial developments. They appreciate how the mesh's inherent strength minimizes the risk of structural failure over time. The advantages of this product extend beyond mere practicality; its availability in various materials such as stainless steel and galvanized wire also adds to its versatility. Choosing the right material is crucial as it impacts the mesh’s performance in different environments. For instance, galvanized wire mesh is preferred for outdoor use due to its resistance to rust and corrosion, ensuring that the integrity of the mesh remains intact even when exposed to harsh weather conditions. Furthermore, the credibility of welded wire mesh is reinforced by its compliance with stringent industry standards and certifications which dictate materials, production processes, and functionality. These standards are established to ensure that every batch of mesh produced meets specific quality benchmarks, providing users with peace of mind regarding the product's performance and longevity. In summary, the use of welded wire mesh with a 100x100mm grid is not only practical but also a testament to engineering excellence. Its application in various industries showcases its resilience, reliability, and adaptability. This product’s consistent performance combined with expert endorsements solidifies its position as a fundamental element in construction and industrial domains. Whether for reinforcing concrete in heavy-duty construction or crafting aesthetically pleasing architectural features, welded wire mesh serves as a pivotal component in advancing modern infrastructure with authority and trust.

Professionals in the construction industry vouch for the reliability of welded wire mesh with 100x100mm dimensions, especially in scenarios demanding high levels of support and longevity. Structural engineers, known for their insistence on safety and precision, often recommend this type of mesh for projects like roadways, bridges, and large-scale commercial developments. They appreciate how the mesh's inherent strength minimizes the risk of structural failure over time. The advantages of this product extend beyond mere practicality; its availability in various materials such as stainless steel and galvanized wire also adds to its versatility. Choosing the right material is crucial as it impacts the mesh’s performance in different environments. For instance, galvanized wire mesh is preferred for outdoor use due to its resistance to rust and corrosion, ensuring that the integrity of the mesh remains intact even when exposed to harsh weather conditions. Furthermore, the credibility of welded wire mesh is reinforced by its compliance with stringent industry standards and certifications which dictate materials, production processes, and functionality. These standards are established to ensure that every batch of mesh produced meets specific quality benchmarks, providing users with peace of mind regarding the product's performance and longevity. In summary, the use of welded wire mesh with a 100x100mm grid is not only practical but also a testament to engineering excellence. Its application in various industries showcases its resilience, reliability, and adaptability. This product’s consistent performance combined with expert endorsements solidifies its position as a fundamental element in construction and industrial domains. Whether for reinforcing concrete in heavy-duty construction or crafting aesthetically pleasing architectural features, welded wire mesh serves as a pivotal component in advancing modern infrastructure with authority and trust.

Next:

Latest news

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025