Дек . 07, 2024 02:31 Back to list

black nail wire factories

The Significance of Black Nail Wire Factories in the Modern Industry

In recent years, the manufacturing sector has undergone profound changes, leading to the emergence of highly specialized production facilities that cater to specific industrial needs. Among these, black nail wire factories have carved out a significant niche, providing essential materials for a variety of applications. This article explores the importance of these factories, their production processes, and their impact on various industries.

Understanding Black Nail Wire

Black nail wire is a type of wire that has been coated with a black oxide finish. This coating not only enhances the aesthetic appeal of the wire but also improves its corrosion resistance, making it ideal for outdoor applications. The wire is commonly used in construction, furniture manufacturing, and various woodworking projects. Its versatility renders it indispensable in both heavy and light industries.

The Production Process

The production of black nail wire involves several steps, each crucial for ensuring the final product meets industry standards. The process begins with high-quality raw materials, typically steel, which is wire-drawn to the desired thickness. Once the wire has been drawn, it undergoes a heating process where it is coated with black oxide. This process not only provides the wire with its characteristic finish but also strengthens it, improving its durability.

After the coating process, the wire is cut to specific lengths and shaped into nails. Factories often employ automated machinery that ensures precision in cutting and shaping, thereby maximizing efficiency and reducing waste. Quality control is an essential aspect of production; every batch of wire undergoes rigorous testing to ensure it meets safety and quality specifications.

The Role of Black Nail Wire Factories

black nail wire factories

The significance of black nail wire factories extends beyond mere production. They play a vital role in the supply chain, providing manufacturers with the raw materials necessary for construction and other industries. Their existence supports local economies by creating jobs and fostering skill development in the workforce. Moreover, these factories often invest in environmentally sustainable practices, recycling materials and minimizing waste—a critical consideration in today’s eco-conscious market.

Applications Across Industries

The applications of black nail wire are vast. In the construction industry, it is used for framing, roofing, and general construction purposes. Its resistance to corrosion makes it suitable for use in areas exposed to the elements. In furniture manufacturing, black nail wire is used in the assembly of various products, ensuring structural integrity and durability.

Additionally, black nail wire has found a place in decorative arts and crafts. Artisans use it for creating sculptures, home décor, and even jewelry, capitalizing on its aesthetic appeal. The fashion industry has also started to incorporate metal components, such as nails, into designs, showcasing the versatility of black nail wire in unexpected areas.

Challenges Faced by Black Nail Wire Factories

Despite their importance, black nail wire factories face several challenges. The global market has become increasingly competitive, with manufacturers from various countries vying for market share. Rising raw material prices and fluctuating demand require factories to be agile and innovative in their production methods. Moreover, the push for sustainable manufacturing practices continues to present both a challenge and an opportunity, as factories must find ways to reduce their carbon footprint while remaining profitable.

Conclusion

Black nail wire factories are crucial players within the manufacturing ecosystem, providing essential materials that satisfy diverse industrial needs. Through innovative production processes and a commitment to quality, these factories contribute significantly to various industries, while also supporting local economies. As the market continues to evolve, the challenge remains for these factories to adapt and thrive, ensuring they remain at the forefront of manufacturing excellence. Their ongoing efforts to innovate and embrace sustainability will not only secure their place in the industry but also lead to a more resilient and responsible manufacturing sector in the future.

-

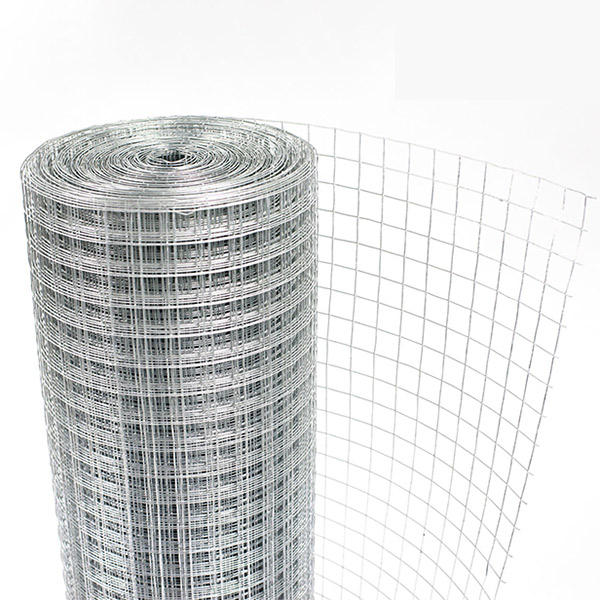

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025