Ноя . 06, 2024 12:21 Back to list

Manufacturer of High-Temperature Resistant Reinforcing Mesh for Various Applications

The Role of Anti-High Temperature Reinforcing Mesh in Modern Construction

In the rapidly evolving construction industry, the use of innovative materials is paramount for enhancing durability and performance. One such innovation is the anti-high-temperature reinforcing mesh, which is designed to withstand extreme temperature conditions, making it indispensable for various construction applications. This article will explore the significance of anti-high-temperature reinforcing mesh, its applications, and the role of manufacturers in ensuring quality and performance.

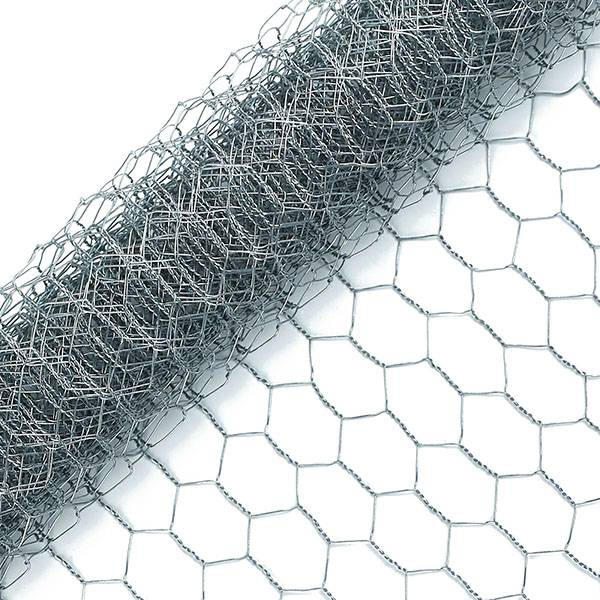

Understanding Anti-High Temperature Reinforcing Mesh

Anti-high temperature reinforcing mesh is a specialized type of reinforcing material made from high-quality steel or composite materials, treated to resist deformation and deterioration when exposed to elevated temperatures. Unlike traditional reinforcing steel, which can lose strength and structural integrity when subjected to high heat, this mesh maintains its properties under thermal stress, thus enhancing the overall resilience of the structures it is integrated into.

Importance of High-Temperature Resistance

In construction scenarios where exposure to high temperatures is expected, such as in industrial facilities, power plants, infrastructure projects, and areas prone to wildfires, the integrity of building materials is crucial. High temperatures can lead to thermal expansion, softening of materials, and ultimately structural failure. The incorporation of anti-high-temperature reinforcing mesh mitigates these risks, ensuring that buildings can withstand extreme thermal environments without compromising safety.

Applications of Anti-High Temperature Reinforcing Mesh

1. Industrial Construction Factories and plants often require materials that can endure high operational temperatures and potential thermal shock. Anti-high-temperature reinforcing mesh is utilized in concrete precast elements, supporting beams, and other structural components to provide additional strength and reliability.

2. Fire-Resistant Structures Buildings in fire-prone areas or those designed to house sensitive equipment must prioritize fire resistance. The application of anti-high-temperature reinforcing mesh in walls, ceilings, and floors significantly improves fire resistance, safeguarding against potential damage and loss.

3. Infrastructure Development In public infrastructure projects, such as bridges and tunnels, materials are frequently exposed to varying temperature conditions. Using anti-high-temperature reinforcing mesh in these structures enhances their durability and extends their service life.

anti high temperature reinforcing mesh manufacturer

4. Geothermal and Energy Applications In geothermal energy plants and similar facilities, thermal management is crucial. Here, anti-high-temperature reinforcing mesh contributes to the stability of concrete that encounters high heat levels, ensuring long-lasting performance.

The Role of Manufacturers

Manufacturers of anti-high-temperature reinforcing mesh play a critical role in the quality and availability of this essential material. They invest in research and development to create products that meet specific industry standards and certifications. Key considerations for manufacturers include

1. Material Selection Utilizing high-grade steel or advanced composites that can withstand elevated temperatures without losing structural integrity is fundamental. Manufacturers must also implement rigorous testing to ensure that their products meet or exceed safety regulations.

2. Fabrication Techniques Advanced fabrication technologies, such as welding and coating techniques, enhance the performance of reinforcing mesh. Manufacturers must ensure their processes lead to consistency in quality and reliability.

3. Customization Different construction projects have unique requirements. Leading manufacturers offer customizable solutions, allowing engineers and architects to select the mesh specifications that best suit their specific needs.

4. Sustainability With growing concerns about environmental impact, manufacturers are increasingly focusing on sustainable production practices, using recycled materials and adhering to eco-friendly processes without compromising product quality.

Conclusion

The incorporation of anti-high-temperature reinforcing mesh represents a significant advancement in construction materials, enhancing the structural integrity and fire resistance of modern buildings and infrastructure. As the demand for durable and reliable construction methods continues to grow, the role of manufacturers in delivering high-quality anti-high-temperature reinforcing mesh will remain critical. By focusing on innovation, quality control, and sustainability, manufacturers can ensure that this essential material meets the needs of the construction industry, ultimately leading to safer and more resilient structures for future generations.

-

Chain Link Fence-Anping County Puersen|Galvanized Steel, Durability, Custom Solutions

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.05,2025

-

Welded Wire Mesh for Industrial Factories: Durable & Strong

NewsAug.05,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025