Ara . 19, 2024 00:49 Back to list

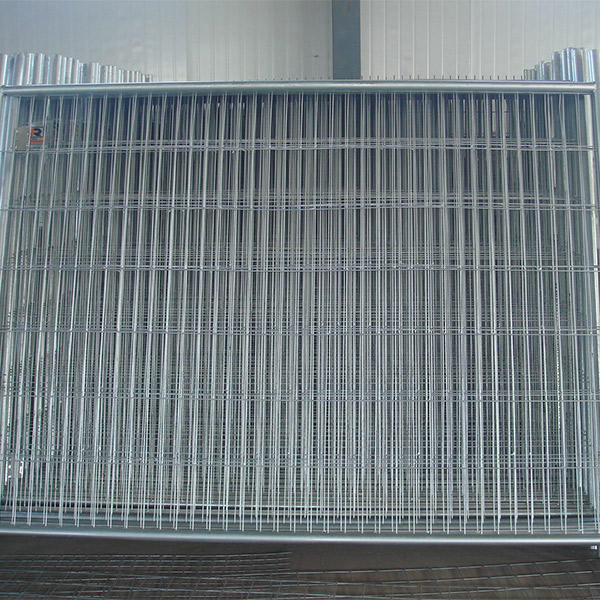

brc welded mesh manufacturer

Understanding BRC Welded Mesh Manufacturing

BRC welded mesh, known for its exceptional strength, durability, and versatility, has gained widespread recognition in various construction and industrial applications. This type of mesh is produced by welding together wires at their intersections, creating a rigid and stable grid. This article delves into the intricacies of BRC welded mesh manufacturing, its applications, advantages, and the factors influencing its production quality.

What is BRC Welded Mesh?

BRC welded mesh is a type of wire mesh that is manufactured from high-quality carbon steel wire, which is then galvanized or coated for enhanced corrosion resistance. The term BRC originates from the British Reinforcement Company, which played a fundamental role in the mesh's development. This mesh is available in various thicknesses, sizes, and configurations, making it suitable for numerous applications, including construction, infrastructure, and specialized industries.

The Manufacturing Process

The manufacturing of BRC welded mesh involves several key steps to ensure the final product meets industry standards and customer specifications.

1. Wire Selection The process begins with choosing high-quality steel wires. The wire diameter and grade are determined based on the intended application and load requirements.

2. Wire Preparation The selected wires undergo cleaning and may be pre-treated, which involves processes such as galvanization to prevent rust and improve durability.

3. Mesh Fabrication The wires are arranged in a grid pattern, typically with uniform spacing. Advanced machinery automates the welding process, wherein wires are welded at their points of intersection to form a rigid mesh. This step is crucial as it determines the overall strength and stability of the mesh.

4. Quality Control Post-manufacturing, the welded mesh undergoes rigorous quality control tests. These tests check for weld integrity, mesh dimensions, and surface finish to ensure compliance with standards.

5. Finishing Finally, the mesh may receive additional treatment, such as coating or painting, before being cut to size and packaged for shipment.

Applications of BRC Welded Mesh

BRC welded mesh is widely used in various sectors due to its robust nature and adaptability. Some common applications include

- Construction The mesh is extensively used as reinforcement in concrete slabs, walls, and foundations, enhancing structural integrity and load-bearing capacity. - Fencing BRC mesh is effective for creating secure fencing solutions for agricultural, industrial, and residential properties.

- Environmental Used in erosion control, retaining walls, and landscaping, BRC mesh helps to stabilize soil and manage water flow

.brc welded mesh manufacturer

- Industrial and Commercial BRC welded mesh serves as flooring in warehouses and factories, offering a slip-resistant surface while allowing for airflow and drainage.

Advantages of BRC Welded Mesh

The popularity of BRC welded mesh can be attributed to several advantages

- Strength and Durability The welding process produces a mesh that can withstand significant loads, making it ideal for heavy-duty applications.

- Cost-Effectiveness Compared to other forms of reinforcement, BRC welded mesh is often more economical, allowing for faster construction times and reduced labor costs.

- Versatility It can be tailored to meet specific requirements, making it useful for a range of projects from residential homes to large infrastructure.

- Ease of Installation The mesh is pre-fabricated and can be quickly installed in various environments, minimizing construction delays.

Factors Influencing Quality

The quality of BRC welded mesh is influenced by several factors throughout the manufacturing process

- Material Quality The choice of wire material is paramount. High-quality, corrosion-resistant steel ensures longevity and performance.

- Welding Techniques Advanced welding techniques and machinery play a critical role in ensuring strong, uniform welds that can sustain the intended loads.

- Manufacturing Standards Compliance with industry standards and certifications, such as ISO or ASTM, is essential in guaranteeing the quality and safety of the finished product.

Conclusion

BRC welded mesh has established itself as a staple in the construction and industrial sectors due to its strength, versatility, and cost-effectiveness. As the demand for durable and reliable materials continues to rise, understanding the manufacturing process and its applications becomes increasingly important. With advancements in technology and manufacturing techniques, BRC welded mesh will continue to evolve, meeting the ever-changing needs of various industries while maintaining superior quality and performance.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025