Nov . 28, 2024 01:47 Back to list

OEM Custom Welded Reinforced Mesh for Enhanced Structural Support and Durability

The Benefits and Applications of OEM Welded Reinforced Mesh

In the modern construction and engineering industries, reliable materials are essential for achieving structural integrity and longevity. One such material that has gained significant popularity is OEM welded reinforced mesh. This versatile product has numerous advantages and a wide array of applications, making it a preferred choice for builders and manufacturers around the globe.

What is OEM Welded Reinforced Mesh?

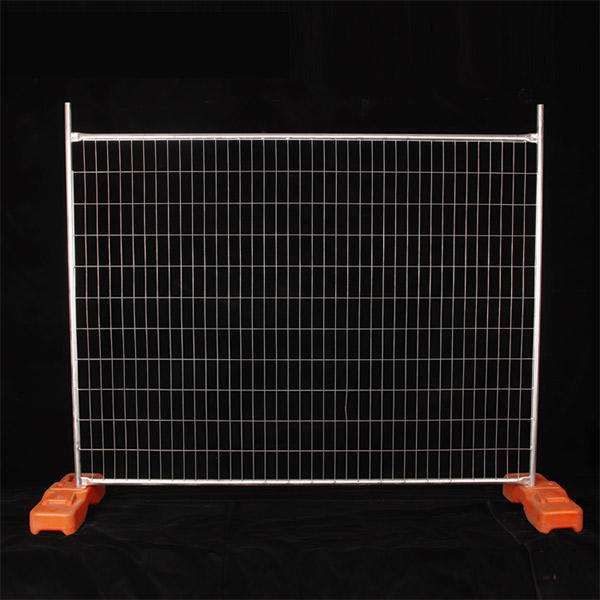

OEM welded reinforced mesh is a type of wire mesh that is manufactured by welding intersecting steel wires together to form a grid-like structure. This process ensures that the wires bond securely, resulting in a product that is both strong and durable. The acronym OEM stands for 'Original Equipment Manufacturer,' which highlights the customized nature of this product; clients can specify sizes, wire diameters, and spacing to suit their particular needs.

Strength and Durability

One of the most significant benefits of OEM welded reinforced mesh is its exceptional strength and durability. The welding process creates a robust framework that can withstand heavy loads and external pressures. This characteristic makes it ideal for use in construction, where structural integrity is paramount. Whether used in floors, walls, or other structural components, welded mesh provides the necessary reinforcement to prevent cracking and failure.

Customization Options

OEM welded reinforced mesh offers extensive customization options, allowing manufacturers and builders to tailor the product to their specific requirements. Clients can choose from various wire diameters, mesh sizes, and coating options such as galvanized or epoxy to enhance corrosion resistance. This flexibility makes it suitable for a range of applications, from residential buildings to large-scale commercial projects, where different load requirements and environmental conditions need to be addressed.

Applications in Construction

The applications of OEM welded reinforced mesh in the construction industry are vast. It is commonly used in

oem welded reinforced mesh

1. Concrete Reinforcement Welded mesh is often embedded within concrete slabs to enhance tensile strength. This not only improves durability but also helps in maintaining the shape of the concrete during the curing process.

2. Pavements In road construction, welded mesh is used to support and stabilize pavements, providing enhanced load-bearing capacity and reducing the risk of cracking.

3. Wall Reinforcement For masonry walls, the mesh serves as an effective reinforcement method, ensuring that structures can withstand various stresses without compromising safety.

4. Industrial Flooring In warehouses and factories, welded mesh is utilized in industrial flooring to provide extra support for heavy machinery and equipment, ensuring a long-lasting surface that can withstand significant wear and tear.

5. Fencing The strength and structural characteristics of welded mesh make it suitable for fencing purposes, providing security and boundary marking for properties, parks, and agricultural lands.

Environmental Considerations

As industries move towards more sustainable practices, the use of OEM welded reinforced mesh aligns with these goals. The materials used in its production are often recyclable, reducing waste and promoting a circular economy. Additionally, the longevity of welded mesh minimizes the need for frequent replacements, ultimately leading to lower resource consumption over time.

Conclusion

In summary, OEM welded reinforced mesh is a vital material in the construction and engineering sectors, offering unmatched strength, versatility, and customization options. Its applications span various aspects of building and infrastructure development, making it an essential component for ensuring structural integrity and safety. As industries continue to prioritize durability and sustainability, the adoption of welded reinforced mesh is likely to increase, solidifying its place as a cornerstone in modern construction practices. Whether you are a manufacturer, builder, or architect, investing in OEM welded reinforced mesh can significantly enhance the quality of your projects and contribute to long-term success in the construction industry.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025