Feb . 18, 2025 01:08 Back to list

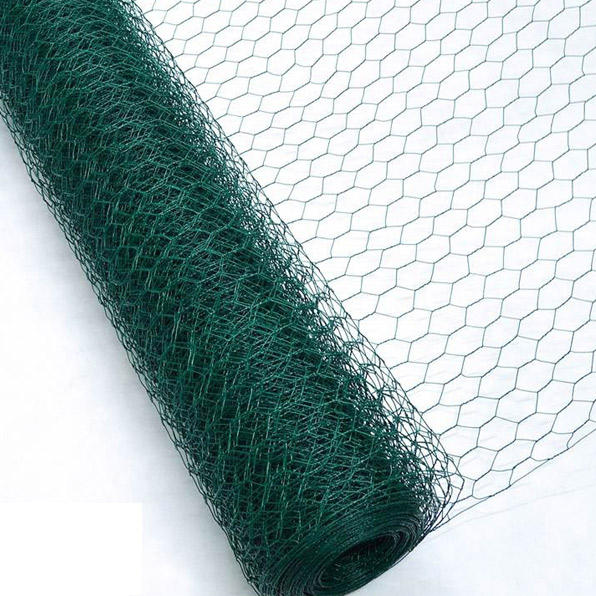

Hexagonal Wire Netting

The construction industry constantly evolves, adapting to new techniques and materials that promise both efficiency and durability. Among these advancements, the concept of OEM twisted rebar has emerged as a significant game changer. Offering a balance between enhanced structural integrity and the flexibility of customization, OEM twisted rebar is rapidly gaining the attention it rightfully deserves.

Professional feedback from engineers and contractors worldwide echo these sentiments, frequently citing increased efficiency in construction and reduced timelines as some of the major benefits. The ease of handling, coupled with the robustness of twisted rebar, makes it a preferred choice for large-scale infrastructure projects, where reliability and speed are crucial. Moreover, the experience of using OEM twisted rebar is transformative when considered within the broader context of eco-friendly construction practices. By reducing the overall quantity of materials needed (thanks to its enhanced strength), projects employing twisted rebar can minimize waste. This results in not only lower raw material costs but also a reduced environmental footprint, making OEM twisted rebar an appealing option in an era where sustainability is paramount. Finally, the authoritative edge that OEM twisted rebar holds over traditional materials is supported by an increasingly comprehensive body of research. Studies have shown that twisted rebar enhances the ductility of the concrete elements it reinforces, providing added resilience to structures in seismically active regions. This capacity to absorb and dissipate energy efficiently during seismic activity is a critical attribute, especially in earthquake-prone areas where safety is non-negotiable. In summary, OEM twisted rebar stands at the intersection of innovation and practicality. Its superior bonding characteristics, customizable nature, and commitment to stringent quality standards render it an invaluable asset in the construction industry. As more projects integrate this advanced form of rebar, the broader community of builders, architects, and engineers continues to discover new ways in which it can enhance structural performance, reduce costs, and contribute positively to sustainable practices.

Professional feedback from engineers and contractors worldwide echo these sentiments, frequently citing increased efficiency in construction and reduced timelines as some of the major benefits. The ease of handling, coupled with the robustness of twisted rebar, makes it a preferred choice for large-scale infrastructure projects, where reliability and speed are crucial. Moreover, the experience of using OEM twisted rebar is transformative when considered within the broader context of eco-friendly construction practices. By reducing the overall quantity of materials needed (thanks to its enhanced strength), projects employing twisted rebar can minimize waste. This results in not only lower raw material costs but also a reduced environmental footprint, making OEM twisted rebar an appealing option in an era where sustainability is paramount. Finally, the authoritative edge that OEM twisted rebar holds over traditional materials is supported by an increasingly comprehensive body of research. Studies have shown that twisted rebar enhances the ductility of the concrete elements it reinforces, providing added resilience to structures in seismically active regions. This capacity to absorb and dissipate energy efficiently during seismic activity is a critical attribute, especially in earthquake-prone areas where safety is non-negotiable. In summary, OEM twisted rebar stands at the intersection of innovation and practicality. Its superior bonding characteristics, customizable nature, and commitment to stringent quality standards render it an invaluable asset in the construction industry. As more projects integrate this advanced form of rebar, the broader community of builders, architects, and engineers continues to discover new ways in which it can enhance structural performance, reduce costs, and contribute positively to sustainable practices.

Next:

Latest news

-

Chain Link Fence-Anping County Puersen|Galvanized Steel, Durability, Custom Solutions

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.05,2025

-

Welded Wire Mesh for Industrial Factories: Durable & Strong

NewsAug.05,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025