Dec . 22, 2024 07:22 Back to list

fiber glass net mesh factories

The Role of Fiberglass Net Mesh Factories in Modern Industries

Fiberglass net mesh has emerged as a crucial material across various sectors due to its unique properties, including strength, durability, and resistance to corrosion and chemicals. With the growing demand for advanced materials in industries such as construction, automotive, and aerospace, fiberglass net mesh factories have become essential players in the global marketplace. This article explores the significance of these factories, the manufacturing process, the applications of fiberglass net mesh, and the future outlook for the industry.

Understanding Fiberglass Net Mesh

Fiberglass net mesh is made from glass fibers that are woven into a mesh pattern, creating a lightweight yet strong material. The mesh is typically coated with resin to enhance its strength and resistance to environmental factors. This material's versatility makes it ideal for various applications, from reinforcing buildings to providing support in plaster and façade systems.

The Manufacturing Process

Fiberglass net mesh factories employ advanced manufacturing techniques to produce high-quality mesh. The process generally involves several key stages

1. Raw Material Preparation The primary raw material for fiberglass mesh is glass fibers. These fibers are produced by melting silica sand and other raw materials at high temperatures and then spinning them into thin strands.

2. Weaving The prepared glass fibers are woven together in a specific pattern to create the desired mesh structure. This step requires precision to ensure uniformity in the product.

3. Coating After weaving, the mesh is coated with resin to provide additional strength and resistance to moisture, chemicals, and UV radiation. The type of resin used can vary depending on the intended application.

4. Cutting and Finishing Once coated, the fiberglass net mesh is cut into specified dimensions and rolls or sheets, ready for distribution. Quality control measures are implemented at various stages to ensure the final product meets industry standards.

Applications of Fiberglass Net Mesh

The applications of fiberglass net mesh are vast and varied

fiber glass net mesh factories

- Construction In the construction industry, fiberglass net mesh is commonly used as a reinforcement material in building walls, ceilings, and floors. It helps in distributing loads and improving structural integrity, making buildings safer and more durable.

- Automotive The automotive sector utilizes fiberglass mesh in components that require strength and lightweight properties, such as body panels and bumpers. This enhances fuel efficiency without compromising safety.

- Aerospace In aerospace applications, fiberglass net mesh is valued for its high strength-to-weight ratio. It is used in structures, components, and insulation, contributing to the overall performance and safety of aircraft.

- Sports and Recreation Fiberglass mesh is also found in sports equipment such as fishing nets, which require durability and flexibility.

The Future Outlook

As industries continue to evolve, so does the demand for advanced materials like fiberglass net mesh. Several factors indicate a positive outlook for fiberglass net mesh factories

1. Sustainability Trends With increasing awareness of environmental issues, many manufacturers are exploring sustainable practices. Fiberglass mesh can be engineered to reduce waste and improve energy efficiency in production.

2. Technological Advancements Innovations in manufacturing processes and materials science are paving the way for higher-quality fiberglass mesh products. This includes developments in resin technology and automated weaving techniques.

3. Expanding Markets Emerging markets in Asia, Africa, and Latin America are witnessing rapid industrialization, leading to a surge in demand for construction and automotive materials. Fiberglass net mesh factories can capitalize on these growth opportunities.

4. Research and Development Ongoing research in composite materials and their applications promises to diversify the use of fiberglass mesh. New types of mesh could meet the specific needs of industries such as renewable energy and advanced materials engineering.

Conclusion

Fiberglass net mesh factories play a vital role in producing one of the most versatile materials used in modern industries. From construction to aerospace, the demand for fiberglass mesh is expected to grow as industries evolve and seek innovative solutions. With advancements in manufacturing techniques and a focus on sustainability, the future looks bright for fiberglass net mesh and the factories that produce it. As we look ahead, it is clear that these factories will continue to be key contributors to the development of high-performance materials, fostering innovation and meeting the challenges of a dynamic global marketplace.

-

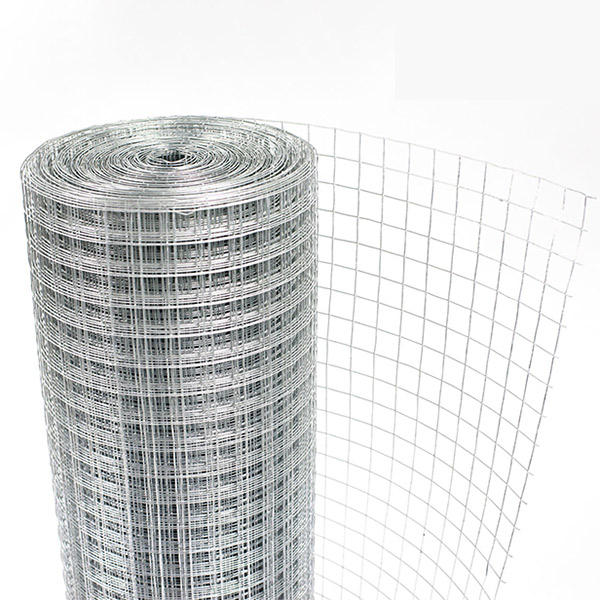

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025