Dec . 10, 2024 16:58 Back to list

Cross Twisted Bars for Durable Steel Grating Solutions by Leading Manufacturers

The Role of Cross Twisted Bars in Steel Grating Manufacturing

Steel grating is an essential component in various industrial applications, known for its durability, strength, and versatility. Among the various components used in steel grating production, cross twisted bars play a pivotal role. This article explores the importance and benefits of using cross twisted bars in the manufacturing of steel grating, emphasizing their attributes, production processes, and diverse applications.

Understanding Cross Twisted Bars

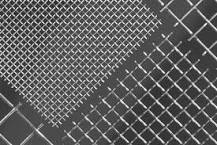

Cross twisted bars are longitudinal bars twisted together in a cross-sectional configuration. This design enhances the structural integrity of the grating, providing superior strength and stability. The twisting of steel bars not only allows for improved load distribution but also reduces the likelihood of deformation under weight. This makes cross twisted bars particularly suited for high-load applications where safety and reliability are paramount.

Manufacturing Process

The manufacturing process of steel grating with cross twisted bars involves several key stages. First, high-grade steel is selected to ensure optimal strength and resistance to corrosion. The raw steel is then cut to the required lengths, followed by the twisting process where bars are twisted together to form a robust lattice-like structure.

Once the bars are twisted, they are welded at intersections to create a stable framework. Various welding techniques, such as electric arc welding or resistance welding, are employed to ensure the joints are secure and can withstand significant stress. After welding, the entire structure undergoes rigorous quality control tests to verify dimensions, strength, and weld integrity, ensuring that the final product meets industry standards.

Advantages of Cross Twisted Bars

cross twisted bar for steel grating manufacturer

2. Increased Slip Resistance The cross-twisted pattern provides additional traction, mitigating the risk of slips and falls, which is particularly important in workplaces where safety is a concern.

3. Corrosion Resistance Steel grating can be coated with protective finishes to enhance its resistance to environmental factors. Cross twisted bars can also be treated with galvanization, ensuring longevity in corrosive environments, such as chemical plants or coastal areas.

4. Versatility Cross twisted bar gratings can be customized to meet the specific needs of different industries. Whether it is for flooring, walkways, or safety barriers, the adaptability of cross twisted bars makes them a preferred choice in various applications.

5. Cost-Efficiency While the initial manufacturing cost might be higher due to the complexity of the twisting and welding processes, the long lifespan and low maintenance requirements of cross twisted bar gratings offer excellent value over time.

Applications

The utilization of cross twisted bars in steel grating extends to numerous industries. In the construction sector, they are commonly used in elevated walkways, platforms, and staircases where robust support is essential. The petrochemical industry relies on cross twisted gratings for refinery platforms and access areas due to their strength and slip-resistant properties.

Furthermore, the transportation sector utilizes this type of grating in railway platforms and vehicle access points where safety and durability are crucial. In municipal applications, cross twisted bar gratings find their place in drainage covers and pedestrian walkways, contributing to public safety and functionality.

Conclusion

In conclusion, cross twisted bars represent a significant advancement in steel grating manufacturing. Their structural integrity, superior load-bearing capabilities, and adaptability to various applications make them an indispensable component in industrial settings. As industries continue to prioritize safety, durability, and cost-effectiveness, the demand for cross twisted bar steel grating is likely to grow, solidifying their role in modern manufacturing practices. Whether for industrial use or public infrastructure, the innovations in design and manufacturing of cross twisted bars mark a turning point in promoting safer and more reliable steel grating solutions.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025