Feb . 15, 2025 17:39 Back to list

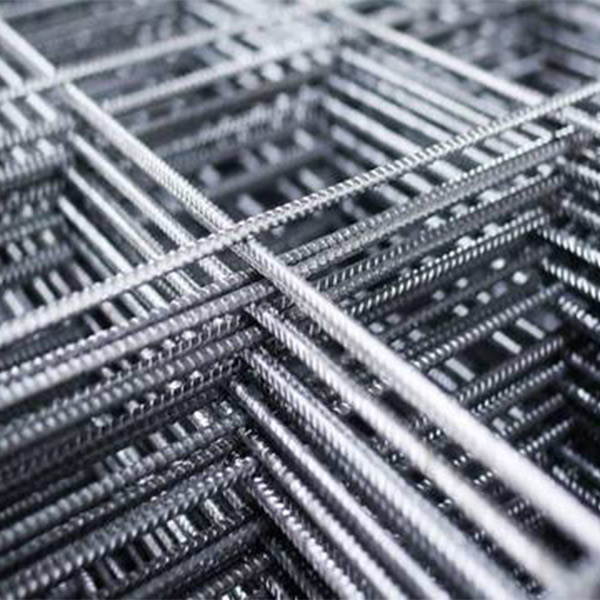

Cold Drawn Wire

As the industrial sector continues to evolve, the need for high-quality materials becomes paramount. One product that has garnered significant attention in recent years is the OEM PVC coated wire. This product is known for its robustness, versatility, and applicability across various fields—qualities that not only set it apart from its competitors but also make it an indispensable asset in numerous industrial applications.

Trustworthiness, intrinsically linked to the product’s reliability and consistency, is another vital consideration. Many businesses that integrate OEM PVC coated wire into their operations do so because they trust the product to maintain consistency across large-scale projects. Case studies and testimonials from previous users frequently cite the product's unwavering quality as a significant factor in their purchasing decision. These endorsements resonate with new users, driving them to invest in the product for their specific needs. Collectively, these factors underscore the unparalleled value that OEM PVC coated wire brings to its users. Whether it is for construction, electrical installations, or agricultural uses, the wire’s adaptability is unmatched. The seamless combination of protective properties, regulatory compliance, and user-reliability propels OEM PVC coated wires to the forefront of preferred materials. In conclusion, when businesses and professionals seek a material that excels in performance, safety, and longevity, OEM PVC coated wire emerges as a leading choice. Its track record, supported by user experience and validated by industry standards, offers a testament to its superior quality and efficacy. As industries advance and the need for robust materials grows, OEM PVC coated wire remains a trusted and authoritative solution, embodying the perfect intersection of expertise and innovation in material technology.

Trustworthiness, intrinsically linked to the product’s reliability and consistency, is another vital consideration. Many businesses that integrate OEM PVC coated wire into their operations do so because they trust the product to maintain consistency across large-scale projects. Case studies and testimonials from previous users frequently cite the product's unwavering quality as a significant factor in their purchasing decision. These endorsements resonate with new users, driving them to invest in the product for their specific needs. Collectively, these factors underscore the unparalleled value that OEM PVC coated wire brings to its users. Whether it is for construction, electrical installations, or agricultural uses, the wire’s adaptability is unmatched. The seamless combination of protective properties, regulatory compliance, and user-reliability propels OEM PVC coated wires to the forefront of preferred materials. In conclusion, when businesses and professionals seek a material that excels in performance, safety, and longevity, OEM PVC coated wire emerges as a leading choice. Its track record, supported by user experience and validated by industry standards, offers a testament to its superior quality and efficacy. As industries advance and the need for robust materials grows, OEM PVC coated wire remains a trusted and authoritative solution, embodying the perfect intersection of expertise and innovation in material technology.

Next:

Latest news

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Eco-Friendly, Heat-Resistant, Durable

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025