Aug . 24, 2024 09:04 Back to list

Galvanized Wire Brick Force Mesh Manufacturing Facilities Overview and Insights

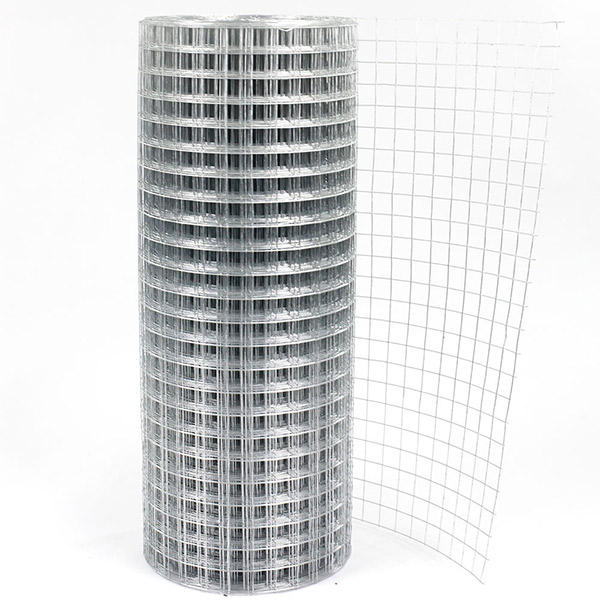

Galvanized Wire Brick Force Mesh Factories An OverviewGalvanized wire brick force mesh has become an essential component in the construction and masonry industry, providing strength, stability, and enhanced durability for various building projects. This specialized mesh is fabricated from high-quality galvanized steel wire, which is coated with zinc to prevent corrosion and extend its lifespan. The production of galvanized wire brick force mesh is facilitated by numerous factories equipped with advanced technology and skilled labor, ensuring the delivery of high-standard products.The significance of galvanized wire mesh lies in its ability to reinforce structures. When incorporated into masonry walls, it helps distribute loads evenly, reducing the risks of cracks and structural failures. This is particularly crucial in areas subject to seismic activities or extreme weather conditions. The mesh acts as a supportive framework, allowing bricks to adhere better and offering additional tensile strength.In recent years, the demand for galvanized wire brick force mesh has surged, driven by booming construction activities worldwide. Factories dedicated to producing this mesh have adapted to meet the varied needs of contractors and builders. They can customize specifications such as wire thickness, mesh size, and zinc coating levels, ensuring clients receive tailored solutions for their projects.One notable trend among these factories is the implementation of environmentally friendly practices. Many manufacturers are now employing eco-conscious methods in their production processes. They prioritize sustainable sourcing of raw materials and utilize energy-efficient technologies to minimize waste and reduce their carbon footprint. This commitment to sustainability not only meets regulatory requirements but also appeals to a more environmentally aware market.Quality control is a vital aspect of production in galvanized wire brick force mesh factories. They conduct rigorous testing on materials and finished products to ensure they meet international standards. This includes assessing factors such as tensile strength, corrosion resistance, and overall durability. By adhering to strict quality metrics, these factories build trust with their clients, establishing long-term business relationships.Moreover, as globalization continues to expand, many factories are looking toward international markets. Exporting galvanized wire brick force mesh has opened new avenues for growth and innovation. By aligning with global standards and tapping into diverse markets, manufacturers can leverage their expertise and increase their competitiveness.In conclusion, galvanized wire brick force mesh factories play a pivotal role in modern construction. Through advanced manufacturing techniques and a commitment to quality and sustainability, these establishments not only contribute to the strength and safety of buildings but also cater to a growing demand for reliable construction materials globally. As the industry continues to evolve, these factories are set to remain at the forefront of innovation and excellence in construction materials.

galvanized wire brick force mesh factories

Galvanized Wire Brick Force Mesh Factories An OverviewGalvanized wire brick force mesh has become an essential component in the construction and masonry industry, providing strength, stability, and enhanced durability for various building projects. This specialized mesh is fabricated from high-quality galvanized steel wire, which is coated with zinc to prevent corrosion and extend its lifespan. The production of galvanized wire brick force mesh is facilitated by numerous factories equipped with advanced technology and skilled labor, ensuring the delivery of high-standard products.The significance of galvanized wire mesh lies in its ability to reinforce structures. When incorporated into masonry walls, it helps distribute loads evenly, reducing the risks of cracks and structural failures. This is particularly crucial in areas subject to seismic activities or extreme weather conditions. The mesh acts as a supportive framework, allowing bricks to adhere better and offering additional tensile strength.In recent years, the demand for galvanized wire brick force mesh has surged, driven by booming construction activities worldwide. Factories dedicated to producing this mesh have adapted to meet the varied needs of contractors and builders. They can customize specifications such as wire thickness, mesh size, and zinc coating levels, ensuring clients receive tailored solutions for their projects.One notable trend among these factories is the implementation of environmentally friendly practices. Many manufacturers are now employing eco-conscious methods in their production processes. They prioritize sustainable sourcing of raw materials and utilize energy-efficient technologies to minimize waste and reduce their carbon footprint. This commitment to sustainability not only meets regulatory requirements but also appeals to a more environmentally aware market.Quality control is a vital aspect of production in galvanized wire brick force mesh factories. They conduct rigorous testing on materials and finished products to ensure they meet international standards. This includes assessing factors such as tensile strength, corrosion resistance, and overall durability. By adhering to strict quality metrics, these factories build trust with their clients, establishing long-term business relationships.Moreover, as globalization continues to expand, many factories are looking toward international markets. Exporting galvanized wire brick force mesh has opened new avenues for growth and innovation. By aligning with global standards and tapping into diverse markets, manufacturers can leverage their expertise and increase their competitiveness.In conclusion, galvanized wire brick force mesh factories play a pivotal role in modern construction. Through advanced manufacturing techniques and a commitment to quality and sustainability, these establishments not only contribute to the strength and safety of buildings but also cater to a growing demand for reliable construction materials globally. As the industry continues to evolve, these factories are set to remain at the forefront of innovation and excellence in construction materials.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025