ก.พ. . 16, 2025 02:34 Back to list

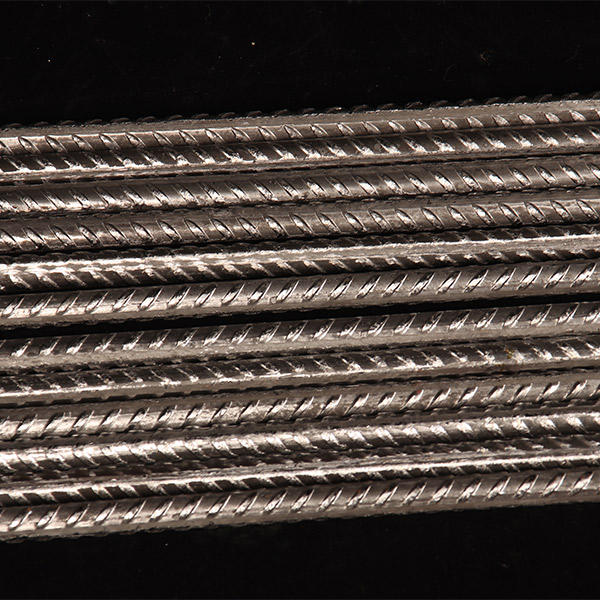

Cold Drawn Wire

For those looking to understand the complexities and applications of OEM twisted annealed wire, it’s paramount to consider the facets that make this product not only specialized but essential across various industries. As an experience-rich entity in the wire manufacturing domain, we delve into why OEM twisted annealed wire stands out, focusing on its unique properties, usage advantages, and market relevance.

From an authoritative standpoint, leading manufacturers of twisted annealed wire continue to innovate, integrating cutting-edge technology to improve product features such as corrosion resistance and tensile strength. This innovation involves continuous research and development, placing the product at the forefront of wire solutions. As authorities in the field, these manufacturers also contribute significantly to setting industry standards, ensuring that quality and safety are never compromised. Trustworthiness is fundamentally reinforced by the transparency and reliability practiced by OEM manufacturers. By providing detailed specifications, usage guidelines, and compliance certifications, manufacturers allow clients to make informed decisions based on their specific applications. This transparency, coupled with consistent quality assurance processes, builds a reliable partnership with end-users. Consideration of these factors is essential for businesses aiming to leverage OEM twisted annealed wire to its fullest potential. The demand for such specialized wire is expected to grow, driven by advancements in construction techniques and agricultural practices, which rely on materials that offer superior strength yet adapt to various demands. In summary, the enduring appeal of OEM twisted annealed wire lies in its amalgamation of high tensile strength and adaptability, supported by a rigorous manufacturing process. From ensuring robust construction integrity to enhancing agricultural productivity, this wire plays a pivotal role across industries. Its evolution is a testament to advancing technological and methodological achievements within wire manufacturing, underscoring its indispensable value in modern industry applications. With expertise, authority, and trust at its core, OEM twisted annealed wire not only addresses current needs but sets a precedence for future wire innovations.

From an authoritative standpoint, leading manufacturers of twisted annealed wire continue to innovate, integrating cutting-edge technology to improve product features such as corrosion resistance and tensile strength. This innovation involves continuous research and development, placing the product at the forefront of wire solutions. As authorities in the field, these manufacturers also contribute significantly to setting industry standards, ensuring that quality and safety are never compromised. Trustworthiness is fundamentally reinforced by the transparency and reliability practiced by OEM manufacturers. By providing detailed specifications, usage guidelines, and compliance certifications, manufacturers allow clients to make informed decisions based on their specific applications. This transparency, coupled with consistent quality assurance processes, builds a reliable partnership with end-users. Consideration of these factors is essential for businesses aiming to leverage OEM twisted annealed wire to its fullest potential. The demand for such specialized wire is expected to grow, driven by advancements in construction techniques and agricultural practices, which rely on materials that offer superior strength yet adapt to various demands. In summary, the enduring appeal of OEM twisted annealed wire lies in its amalgamation of high tensile strength and adaptability, supported by a rigorous manufacturing process. From ensuring robust construction integrity to enhancing agricultural productivity, this wire plays a pivotal role across industries. Its evolution is a testament to advancing technological and methodological achievements within wire manufacturing, underscoring its indispensable value in modern industry applications. With expertise, authority, and trust at its core, OEM twisted annealed wire not only addresses current needs but sets a precedence for future wire innovations.

Next:

Latest news

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Security&Versatile Applications

NewsAug.08,2025

-

Chain Link Fence: Comprehensive Guide to Features, Applications, and Specifications - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.08,2025

-

100x100cm Square Reinforcing Mesh - Direct Factory Supply

NewsAug.08,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence - Durable, Versatile Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence: Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025