ส.ค. . 10, 2024 04:45 Back to list

High-Quality OEM Cold Drawn Spring Wire for Durable and Reliable Industrial Applications

The Significance of OEM Cold Drawn Spring Wire in Modern Manufacturing

In the realm of manufacturing, the materials used play a pivotal role in determining the performance and durability of the final products. One such essential material is OEM (Original Equipment Manufacturer) cold drawn spring wire. This specialized wire is fundamental in creating springs that are integral to a wide range of applications, from automotive components to industrial machinery.

Cold drawn spring wire is produced through a process that involves pulling wire through a die at room temperature, which enhances its mechanical properties. The cold drawing process not only increases the tensile strength of the wire but also improves its surface finish, yielding a product that is both strong and aesthetically appealing. The tight tolerances and consistent dimensions achieved through this process are crucial in applications where precision is vital.

The Significance of OEM Cold Drawn Spring Wire in Modern Manufacturing

The demands of modern technology require manufacturers to produce components that can withstand extreme conditions. OEM cold drawn spring wire meets these challenges by offering a higher yield strength and better fatigue performance than conventional wire. As such, products derived from this wire can sustain repeated loading and unloading cycles without succumbing to failure, ultimately extending the lifespan of the components.

oem cold drawn spring wire

Moreover, OEM cold drawn spring wire is widely utilized in the automotive industry. Springs in vehicles—such as suspension springs, valve springs, and clutch springs—are critical for performance and safety. The ability to tailor specifications allows manufacturers to optimize the wire's performance for specific vehicle types and driving conditions. This customized approach enhances vehicle stability, handling, and comfort, demonstrating the essential role of OEM spring wire in modern automotive engineering.

In addition to the automotive sector, the industrial machinery sector heavily relies on OEM cold drawn spring wire. Equipment such as conveyor systems, compressors, and pneumatic tools require springs that can endure constant stress. The reliability of these components ensures that operations run smoothly and efficiently, reducing downtime and maintenance costs.

Sustainability and eco-friendliness are also becoming increasingly important in manufacturing. The cold-drawing process is energy-efficient compared to other methods, like hot rolling. Furthermore, many manufacturers now focus on producing wire from recycled materials, contributing to a circular economy while maintaining high-quality standards.

In conclusion, OEM cold drawn spring wire represents a critical material in contemporary manufacturing, offering a multifaceted solution for engineers and designers across various industries. Its unique properties, tailored specifications, and capability to withstand extreme conditions make it an indispensable component of modern machinery and vehicles. As technology progresses, the importance of this specialized wire will only continue to grow, reinforcing its position as a cornerstone of innovative engineering and manufacturing solutions.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

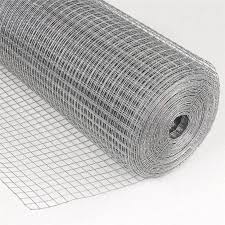

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025