ส.ค. . 28, 2024 01:24 Back to list

Quality Galvanized Wire Manufacturers - Durable & Reliable Wire Solutions

Understanding Galvanized Wire Manufacturers A Comprehensive Overview

Galvanized wire is an essential component in various industries, known for its durability and resistance to corrosion. It is primarily made from steel wire that has been coated in zinc to protect it from environmental factors. The process of galvanization not only strengthens the wire but also increases its lifespan, making it a preferred choice for numerous applications, such as construction, fencing, wire mesh, and agricultural uses. In this article, we explore the role of galvanized wire manufacturers, the production process, and the various applications of galvanized wire.

The Role of Galvanized Wire Manufacturers

Galvanized wire manufacturers play a crucial role in producing high-quality wire products that meet various specifications and requirements. These manufacturers are responsible for the entire production process, from sourcing raw materials to the final product delivery. They adhere to industry standards and quality control measures to ensure that the galvanized wire produced is reliable and efficient for its intended use.

Many manufacturers specialize in a specific type of galvanized wire, such as hard-drawn or soft-drawn wire, depending on customer needs. Additionally, they may offer customizable options, allowing customers to specify dimensions, gauges, and coatings based on their unique applications. This flexibility is vital in catering to the diverse needs of different industries.

The Production Process

The production of galvanized wire typically begins with the drawing of steel wire from larger rods into finer diameters. This process involves pulling the wire through a series of dies, which helps achieve the desired thickness. Once the wire is drawn to the required diameter, it undergoes a cleaning process to remove any impurities and oils.

galvanized wire manufacturers

After cleaning, the wire is subjected to the galvanization process, which usually involves either hot-dip galvanization or electro-galvanization. Hot-dip galvanization entails dipping the wire into molten zinc, resulting in a thick, durable coating. In contrast, electro-galvanization involves applying a zinc coating through electroplating, offering a thinner, more uniform finish. The method chosen often depends on the specific requirements of the final product.

Applications of Galvanized Wire

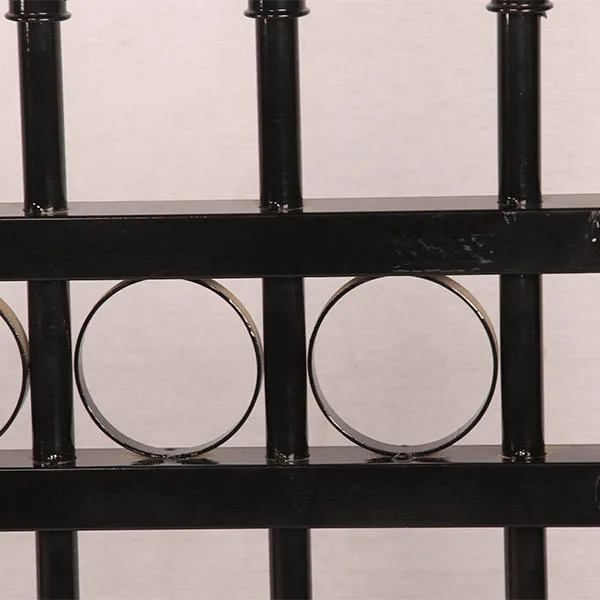

Galvanized wire finds applications across a wide range of industries due to its strength and corrosion resistance. One of the most common uses is in fencing, where it serves as an effective barrier for livestock and property protection. Additionally, it is utilized in the construction industry for various purposes, including reinforcing concrete and manufacturing wire mesh products.

In agriculture, galvanized wire is used to create trellises for climbing plants and to support produce during growth. It is also commonly found in the production of cable and automotive components.

Conclusion

In summary, galvanized wire manufacturers are pivotal in providing robust, corrosion-resistant wire products essential for numerous industries. Their adherence to quality standards, innovative production processes, and ability to cater to specific customer demands contribute to the widespread use of galvanized wire. As industries continue to evolve, the role of these manufacturers will remain critical in ensuring the availability of high-quality wire solutions that meet the ever-changing market needs.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025