Oct . 14, 2024 03:43 Back to list

reinforcing mesh used building manufacturers

Reinforcing Mesh Used in Building Manufacturing An Essential Component

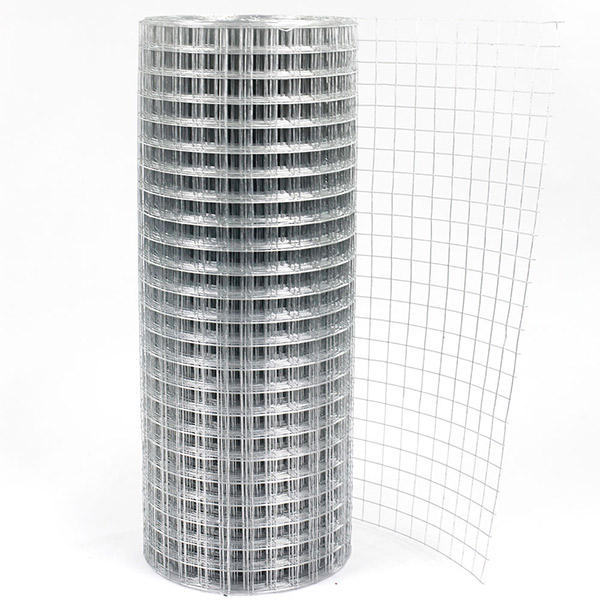

In the construction industry, structural integrity is paramount. One of the key components that contribute to this is reinforcing mesh. Used predominantly in concrete applications, reinforcing mesh enhances the strength and durability of structures, making it a staple in modern building practices.

Reinforcing Mesh Used in Building Manufacturing An Essential Component

The process of manufacturing reinforcing mesh involves several steps. Initially, high-quality raw materials, usually low carbon steel wires, are selected for their tensile strength and ductility. These wires are then cold drawn and cut to exact specifications. After that, they are welded or twisted together to form various patterns, commonly square or rectangular grids, depending on the intended application. Different sizes and mesh configurations can be produced, allowing builders to choose the most suitable option for their specific needs.

reinforcing mesh used building manufacturers

One of the significant advantages of using reinforcing mesh in construction is its cost-effectiveness. While the initial investment may seem considerable, the long-term benefits significantly outweigh the upfront costs. Structures reinforced with mesh are less likely to suffer from structural failures or require extensive repairs, thus saving resources and money over time. Moreover, as buildings become more sustainable and energy-efficient, the durability provided by reinforcing mesh aligns perfectly with modern construction ideals.

Additionally, the popularity of prefabrication in the construction industry has increased the demand for reinforcing mesh. Manufacturers produce standardized sheets that can be used in various applications, speeding up the building process and ensuring consistent quality. This efficiency not only helps in reducing labor costs but also minimizes waste, contributing to more sustainable building practices.

With advancements in technology, the reinforcing mesh manufacturing process has seen improvements in terms of precision and efficiency. Automated systems allow for quicker production times and greater accuracy in mesh design, which is crucial for meeting the stringent standards of modern construction. Furthermore, innovations in composite materials, such as fiberglass reinforcement, are gaining traction due to their corrosion resistance and lighter weight, offering a viable alternative to traditional steel mesh.

In conclusion, reinforcing mesh is an indispensable element in building manufacturing, playing a crucial role in ensuring the reliability and longevity of structures. As the construction sector continues to evolve, the emphasis on quality materials like reinforcing mesh will remain essential for producing safe and enduring buildings. Manufacturers must keep pace with technological advancements to enhance their products and meet the growing demands of the industry, ultimately contributing to the development of more resilient infrastructures worldwide.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025