Sep . 21, 2024 15:50 Back to list

6mm welded panel

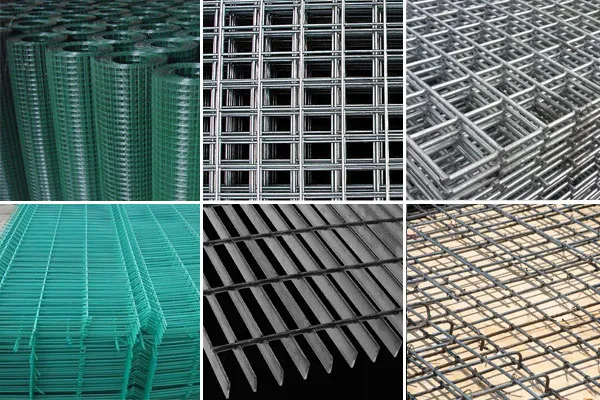

The Versatility and Benefits of 6mm Welded Panels

Welded panels have become an essential component in various construction and manufacturing processes due to their strength, durability, and versatility. Among the various specifications available in the market, 6mm welded panels stand out for their balance of thickness and sturdiness, catering to a wide array of applications across different industries.

Composition and Structure

At the core of 6mm welded panels is the process of welding, which involves fusing metal components together to create a robust structure. Typically made from materials such as steel, aluminum, or stainless steel, these panels are engineered to offer optimal performance in demanding conditions. The 6mm thickness provides a level of durability that is suitable for structural support while also maintaining a reasonable weight for ease of handling and installation.

Applications

One of the most common uses for 6mm welded panels is in the construction industry

. They are frequently employed as fencing, guardrails, or partitions due to their strength and ability to resist deformation under load. In industrial settings, these panels are often used in fabricating storage racks, shelving systems, and other equipment that requires reliable support. The automotive and aerospace industries also benefit from 6mm welded panels, where precision and strength are critical.In addition to industrial applications, welded panels are increasingly popular in the realm of architectural design. Designers and architects are utilizing these panels to create visually appealing structures that also adhere to safety and durability standards. The sleek, modern look of welded panels can enhance the aesthetic value of both residential and commercial buildings.

6mm welded panel

Benefits

The advantages of 6mm welded panels extend beyond their physical attributes. One significant benefit is their resistance to environmental factors. When treated or coated properly, these panels can withstand moisture, rust, and corrosion, making them suitable for outdoor applications or in environments with high humidity. This longevity translates into lower maintenance costs over time, providing economic advantages to businesses and homeowners alike.

Moreover, the fabrication process of welded panels allows for customization. Manufacturers can tailor the size, shape, and finish of the panels to meet specific project requirements. This flexibility enables clients to maximize their design options while ensuring that the panels meet structural and aesthetic needs.

Sustainability Considerations

As industries shift towards more sustainable practices, the use of 6mm welded panels aligns well with eco-friendly initiatives. Steel and aluminum are highly recyclable materials, which means that at the end of their lifespan, these panels can be repurposed without significant environmental impact. Investing in welded panels not only supports immediate project needs but also contributes to a circular economy model.

Conclusion

In summary, 6mm welded panels offer a unique combination of strength, versatility, and aesthetic appeal, making them a popular choice across various sectors. Their ability to withstand harsh conditions, coupled with customization options, ensures they meet the diverse needs of modern construction. As industries continue to value sustainability, the recycled nature of these panels positions them as a forward-thinking solution in today’s marketplace. Whether for industrial, commercial, or residential use, 6mm welded panels provide a reliable and efficient option for builders and designers alike.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025