నవం . 12, 2024 14:40 Back to list

High-Quality Cold Drawn Steel Bars for OEM Applications and Custom Solutions

Understanding OEM Cold Drawn Steel Bars

Cold drawn steel bars are a vital component in various industries due to their excellent mechanical properties and surface finish. The term OEM, or Original Equipment Manufacturer, highlights the importance of these bars in the manufacturing of high-quality parts and assemblies tailored for specific applications.

What is Cold Drawing?

Cold drawing is a metalworking process utilized to produce steel bars with precise dimensions and enhanced mechanical properties. During this process, steel is pulled through a die at room temperature, reducing its diameter while increasing its tensile strength. This results in a finer surface finish and tighter tolerances, making cold drawn bars suitable for applications that demand high precision.

Benefits of Cold Drawn Steel Bars

1. Improved Mechanical Properties The cold drawing process aligns the steel’s grain structure, leading to improved yield and tensile strength. This means components made from cold drawn steel bars can withstand greater loads and resist deformation better than those made from hot rolled steel.

2. Enhanced Surface Quality The surface finish of cold drawn steel bars is typically smoother and cleaner compared to their hot rolled counterparts. A rough surface can be detrimental in applications where friction or aesthetics are important. Therefore, the cold drawing process is particularly valuable in sectors like automotive and aerospace, where surface quality is critical.

oem cold drawn steel bar

3. Dimensional Precision Cold drawn bars offer greater dimensional accuracy. This reduced variability in size allows for efficient assembly in manufacturing processes, saving time and reducing waste.

4. Versatility OEM cold drawn steel bars are available in various shapes and sizes, such as round, square, and rectangular configurations. This versatility makes them applicable in a wide range of industries, from construction to machinery manufacturing.

Applications of Cold Drawn Steel Bars

Due to their advantageous properties, cold drawn steel bars find applications across numerous fields. In automotive manufacturing, they are used for producing axles, shafts, and fasteners. In the machinery sector, these bars serve as critical components in gear systems and hydraulic equipment. Additionally, their use in structural applications ensures durability and safety in construction projects.

Conclusion

In conclusion, OEM cold drawn steel bars play an essential role in modern manufacturing. Their enhanced mechanical properties, superior surface finish, and precise dimensions make them the material of choice for high-performance applications. Companies looking to advance their product quality and reliability should consider the incorporation of cold drawn steel bars into their manufacturing processes. As industries continue to evolve, these bars will remain at the forefront, driving innovation and meeting the ever-changing demands of various sectors. By understanding the benefits and applications of cold drawn steel, manufacturers can leverage this material to achieve their operational goals effectively.

-

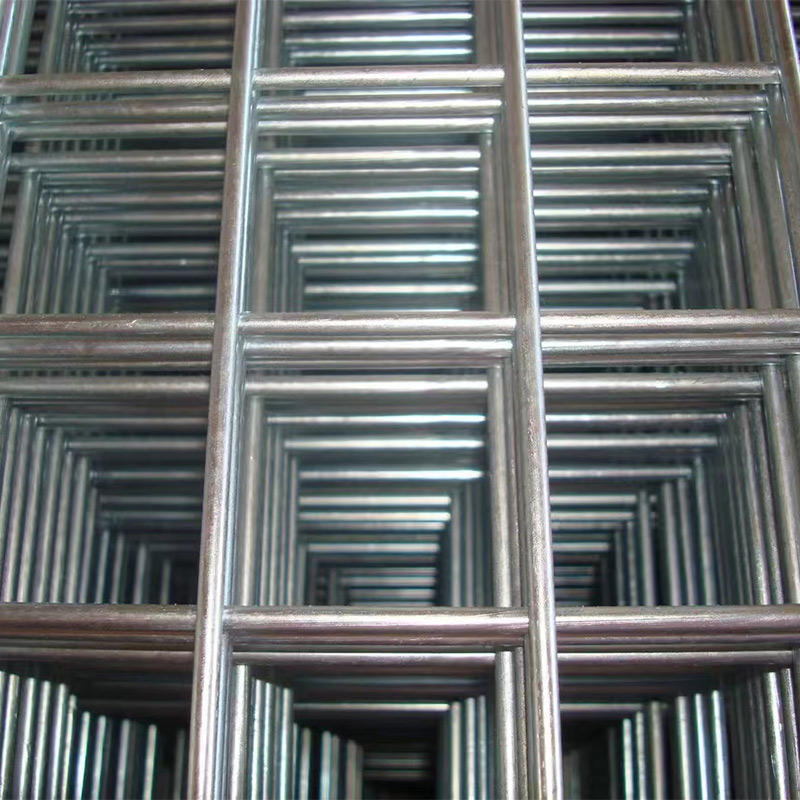

Industrial-Grade Welded Wire Mesh for Factories & Suppliers | Durable

NewsJul.25,2025

-

Precision Cold Drawn Wire: High Strength & Durability Solutions

NewsJul.25,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025