டிசம்பர் . 12, 2024 10:11 Back to list

welded mesh for bridge factory

The Importance of Welded Mesh for Bridge Construction An Overview

Welded mesh, a versatile and durable construction material, plays a crucial role in the bridge-building industry. As the demand for reliable and robust structures continues to rise, welded mesh has become an essential component for ensuring the integrity, safety, and longevity of bridges. This article explores the significance of welded mesh in bridge construction, its various applications, and the benefits it offers to manufacturers and engineers.

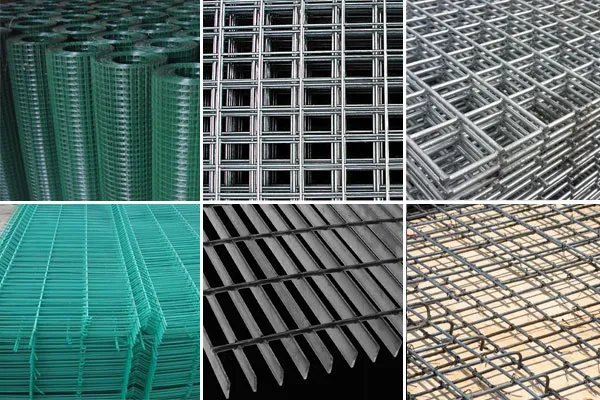

What is Welded Mesh?

Welded mesh is a grid-like structure made from metal wires that are welded together at their intersections. These meshes are available in various sizes, shapes, and materials, making them incredibly adaptable for different construction needs. Typically manufactured from steel, stainless steel, or other materials, welded mesh can be produced in different diameters and spacing arrangements to meet specific load and structural requirements.

Applications in Bridge Construction

Welded mesh serves multiple vital functions in bridge construction. Primarily, it is used as reinforcement in concrete elements, providing additional strength and stability. Concrete, although strong in compression, is weak in tension; therefore, the inclusion of welded mesh helps to evenly distribute tensile stresses throughout the structure, reducing the risk of cracking and failure.

In addition to reinforcement, welded mesh is also employed in various forms, such as

1. Decking Systems Welded mesh is often incorporated into bridge decking to provide a solid foundation for the surface layers, ensuring that the deck can withstand heavy traffic loads.

2. Parapets and Guardrails Bridges require safety features to protect pedestrians and vehicles. Welded mesh can be fabricated to create robust parapets and guardrails, providing essential safety barriers.

welded mesh for bridge factory

Benefits of Using Welded Mesh

There are several advantages to using welded mesh in bridge construction

1. Enhanced Strength and Stability The primary function of welded mesh is to improve the structural integrity of concrete. By reinforcing key components such as beams, slabs, and columns, welded mesh enhances the bridge's resistance to various loads while minimizing the likelihood of structural failures.

2. Cost-Effectiveness Welded mesh can reduce construction costs by simplifying the reinforcement process. Its ready-to-use format means it can be easily integrated into existing designs, reducing labor time and material waste.

3. Durability and Longevity Bridges are subjected to harsh environmental conditions, including moisture and temperature fluctuations. Welded mesh, particularly when made from high-quality materials, offers outstanding durability, ensuring the bridge remains functional and safe for years to come.

4. Versatility in Design The adaptability of welded mesh allows engineers and architects to explore innovative designs without compromising on strength. This versatility is vital in modern bridge construction, where unique shapes and traffic requirements must be accommodated.

5. Ease of Installation Welded mesh is relatively straightforward to install, which further streamlines the construction process. Its uniformity and consistency allow for quick placement and secure bonding with surrounding materials, expediting the overall project timeline.

Conclusion

In conclusion, welded mesh is an indispensable element in bridge construction, offering a reliable solution for enhancing strength, stability, and safety. Its various applications—from integral structural support to aesthetic features—underscore its importance in modern engineering practices. As infrastructure needs continue to evolve, the role of welded mesh in bridge manufacturing will undoubtedly expand, solidifying its place as a vital component in creating durable and functional bridges that meet the demands of today and the future. As cities grow and transportation needs increase, the use of welded mesh will continue to support the development of resilient infrastructure that can withstand the test of time.

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025