Novemba . 05, 2024 19:30 Back to list

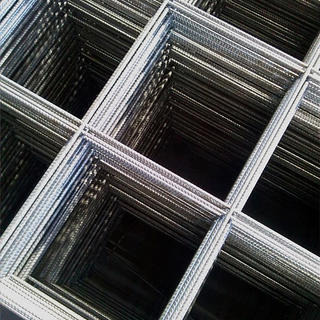

steel construction reinforcement mesh manufacturer

The Role of Steel Construction Reinforcement Mesh Manufacturers in Modern Construction

In the realm of modern construction, the importance of structural integrity cannot be overstated. Buildings, bridges, and other infrastructural elements must withstand various stresses and strains to ensure safety and durability. This is where steel construction reinforcement mesh comes into play, acting as a backbone in concrete structures. The demand for such reinforcing materials has led to the rise of specialized manufacturers dedicated to producing high-quality reinforcement mesh, playing a crucial role in the construction industry.

Understanding Steel Reinforcement Mesh

Steel reinforcement mesh, often referred to as reinforcement mesh or rebar mesh, consists of a grid of steel bars or wires that are welded together to form a network. This mesh is embedded within concrete, providing tensile strength and helping to prevent cracks or failures due to loads, temperature changes, or settling. The primary purpose of reinforcement mesh is to enhance the structural capacity of concrete, which is strong in compression but weak in tension.

The Manufacturing Process

The process of manufacturing high-quality reinforcement mesh involves several key steps. It begins with sourcing raw materials, typically high-carbon steel, known for its strength and durability. Manufacturers must ensure that the steel meets specific quality standards to withstand the rigors of construction.

Once the raw materials are secured, they undergo a series of processing stages, including cutting, cold drawing, and welding. These processes shape the steel into the desired mesh configuration. Manufacturers also employ advanced machinery and technology to ensure precision and consistency in the finished product. This process culminates in the quality inspection phase, where the mesh is tested for strength, durability, and conformity to industry standards.

Quality Standards and Compliance

Quality is paramount in the production of steel reinforcement mesh. Manufacturers are required to comply with various national and international standards, which dictate the specifications for materials, production methods, and performance. For instance, in the United States, products might need to adhere to ASTM standards, while in Europe, EN standards are commonly followed. These regulations ensure that the reinforcement mesh not only meets structural requirements but also contributes to the overall safety and longevity of construction projects.

steel construction reinforcement mesh manufacturer

The Importance of Customization

One of the key advantages of specialized reinforcement mesh manufacturers is their ability to offer customized solutions. Construction projects vary widely in terms of size, scope, and design, and there is no one-size-fits-all solution for reinforcement. Manufacturers can tailor the mesh dimensions, wire diameters, and spacing to fit the specific needs of a project. This level of customization ensures that engineers and architects can maximize the structural performance of concrete elements, potentially leading to cost savings and enhanced safety.

The Role of Technology in Manufacturing

The steel construction industry has witnessed significant advancements in technology over the years. Manufacturers are increasingly adopting automation and robotics to enhance production efficiency. Automated welding processes, for example, improve the consistency and quality of the mesh while reducing labor costs. Additionally, implementing Computer Numerical Control (CNC) technology allows for precise cutting and shaping, further enhancing customization capabilities.

Furthermore, manufacturers are leveraging innovative software solutions for design and planning, enabling better collaboration with architects and construction teams. This technology ensures that the right materials are delivered at the right time, minimizing delays and optimizing project timelines.

Sustainability Practices in Manufacturing

As the construction industry continues to evolve, sustainability has become a focal point. Many steel construction reinforcement mesh manufacturers are adopting environmentally friendly practices in their operations. This includes using recycled steel, reducing waste, and implementing energy-efficient production processes. Emphasizing sustainability not only aligns with global initiatives but also meets the increasing demand from consumers for eco-friendly construction materials.

Conclusion

Steel construction reinforcement mesh manufacturers are invaluable partners in the construction industry, contributing significantly to the safety and durability of modern infrastructure. Through a commitment to quality, customization, and technology, these manufacturers ensure that architects and engineers have the right materials to build resilient structures. As the industry moves towards more sustainable practices, their role will continue to evolve, reflecting the changing needs and values of society. In essence, they are not just suppliers, but pivotal players in shaping the future of construction.

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability, Flexibility, Cost-Effective

NewsAug.11,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Security, Versatile Application

NewsAug.10,2025