Oktoba . 30, 2024 17:16 Back to list

black annealing furnace for binding wire factories

The Importance of Black Annealing Furnaces for Binding Wire Factories

In the manufacturing of binding wires, the annealing process plays a pivotal role in ensuring the quality and performance of the final product. Among the various types of annealing processes, black annealing is particularly significant. This technique is widely employed in binding wire factories to enhance ductility, tensile strength, and overall wire performance.

Black annealing is a controlled heating process that treats wires, typically made of low carbon steel, to relieve internal stresses and create a uniform structure. The process involves heating the wire to a temperature between 600°C to 700°C in a reducing atmosphere. This environment prevents the formation of iron oxide on the wire surface, giving it a characteristic black finish. The resulting blackened wire not only possesses improved mechanical properties but also exhibits enhanced resistance to corrosion.

One of the core benefits of black annealing for binding wire factories is the resulting increase in the ductility of the wire. Ductile wires are essential in applications where flexibility and the ability to undergo deformation are crucial. Binding wires are commonly used in various industries, from construction to agriculture, to secure materials. A ductile wire can absorb energy during bending or twisting without breaking, making it a favored choice among manufacturers.

black annealing furnace for binding wire factories

Furthermore, black annealing significantly improves the tensile strength of wires. The controlled heating process allows for any brittle structures to be transformed into a more malleable form, enhancing the wire's load-bearing capacity. This is particularly important in construction settings where binding wires must support heavy loads and endure various environmental stresses.

Moreover, the black finish of annealed wires provides an added advantage in terms of aesthetic appeal. Wires with a uniform black coating are often preferred for their sleek appearance, which can blend seamlessly into various applications.

In conclusion, black annealing furnaces are an integral component of binding wire factories, contributing to the production of high-quality, durable, and aesthetically pleasing wires. By enhancing mechanical properties and providing resistance against corrosion, black annealing ensures that binding wires can meet the demands of diverse applications, ultimately supporting the efficiency and reliability of construction and manufacturing processes. As industries continue to evolve, the importance of such technologies in producing superior materials will remain paramount.

-

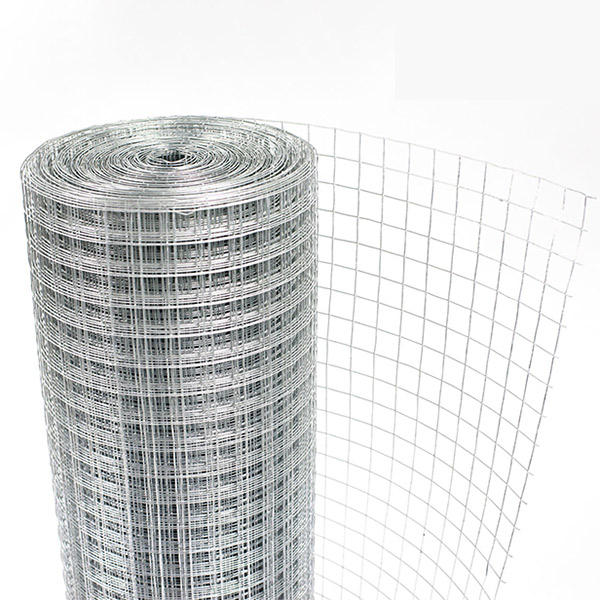

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025