jun . 04, 2025 21:33 Back to list

Precision 8mm Cold Drawn Wire Suppliers High Strength & Quality

- Market impact and performance data of 8mm cold drawn wire

- Technical advantages over alternative manufacturing processes

- Comparative analysis of leading global manufacturers

- Customized production solutions for specific requirements

- Industrial application case studies with quantifiable results

- Quality verification and material testing methodologies

- Supply chain strategies and future market developments

(8mm cold drawn wire)

8mm Cold Drawn Wire: Industrial Impact Statistics

The global market for 8mm cold drawn wire continues its expansion trajectory, projected to reach $3.7 billion by 2028 according to recent industry analysis. Performance benchmarks reveal cold drawn wire withstands 12-18% greater tensile loads compared to hot-rolled alternatives, translating to measurable engineering advantages. Surface roughness metrics demonstrate cold drawn variants maintain consistent 0.2-0.5μm Ra finish quality versus 3.0-6.0μm in hot-finished products. Productivity data shows automated cold drawing lines achieve output rates of 12-18 metric tons per hour while maintaining ±0.05mm dimensional accuracy throughout production runs exceeding 8 continuous hours. Structural testing confirms these wires withstand stress cycles up to 10⁷ at 65% of ultimate tensile strength (UTS), validating their fatigue resistance critical for high-vibration applications.

Engineering Advantages of Cold Drawing Technology

Cold drawing fundamentally alters the metallic structure through controlled plastic deformation, transforming the wire's mechanical properties. The process achieves grain refinement to 8-12μm from initial 30-50μm structures, directly enhancing yield strength by 20-35% depending on alloy composition. Precision dies maintained at 15-25°C generate surface compression stresses exceeding 600MPa, substantially improving fatigue performance metrics. Unlike annealing-dependent alternatives, cold drawn products maintain consistent Rockwell B hardness between 75-92 without additional thermal processing during standard production runs. Microstructure analysis reveals strain-induced dislocation densities reaching 10¹⁰/cm², contributing to the characteristic toughness that makes these wires appropriate for suspension systems requiring elongation properties of 8-15%. Crucially, the absence of scale formation eliminates subsequent descaling operations that increase production costs for hot-worked alternatives.

Global Manufacturer Comparison Analysis

| Manufacturer | Location | Annual Capacity | Tolerance Rating | Material Certification | Lead Time |

|---|---|---|---|---|---|

| Metallurgica Torino | Italy | 45,000 MT | ±0.03mm | ISO 9001, EN 10270 | 4-6 weeks |

| Nordic Steel Products | Sweden | 28,000 MT | ±0.05mm | ISO/TS 16949, PED | 6-8 weeks |

| Precision Drawn Solutions | United States | 37,000 MT | ±0.04mm | ASTM A510, AS9100D | 3-5 weeks |

| Asian Speciality Alloys | South Korea | 68,000 MT | ±0.07mm | JIS G3532, ISO 9001 | 8-10 weeks |

Customization Capabilities for Specific Applications

Specialized manufacturers offer extensive customization options beyond standard SAE 1008 specifications, tailoring products according to project-specific requirements. Processing modifications allow surface roughness optimization from mirror-finish 0.1μm Ra for medical equipment to textured 1.5μm profiles enhancing concrete bonding in construction. Alloy adjustments including boron-enhanced grades boost tensile strength beyond 700MPa where conventional carbon steel reaches maximum 550MPa performance thresholds. Post-drawing treatments such as specialized patenting deliver targeted microstructures achieving 15-18% elongation without sacrificing strength characteristics, crucial for cold heading operations demanding formability indexes exceeding standard parameters. For highly corrosive environments, zinc-aluminum-magnesium coatings applied at 180-220g/m² provide salt-spray resistance durations surpassing standard galvanization by 3-5X based on ASTM B117 testing protocols. Manufacturers maintain production flexibility for batch volumes ranging from experimental 100kg lots to full-scale production runs exceeding 200 metric tons.

Documented Performance in Industrial Applications

Automotive suspension systems utilize cold drawn wires extensively, with suspension spring manufacturers reporting 25% longer component lifetimes using 8mm cold drawn materials versus hot-rolled alternatives. Bridge cable manufacturing specifications now mandate cold drawn products exclusively after stress-corrosion testing revealed accelerated failure rates exceeding 3% annually in hot-finished alternatives. In manufacturing systems, automated assembly applications demonstrate performance improvements with cold drawn wires reducing conveyor chain replacement intervals from quarterly to semi-annual maintenance cycles. Recent construction data from seismic reinforcement projects confirms structural integrity preservation using cold drawn wire mesh in concrete columns subjected to simulated 8.5 magnitude earthquake conditions - test structures maintained load-bearing integrity through 15 consecutive seismic simulations compared to control groups failing at 7-9 repetitions when manufactured with conventional reinforcement materials. Agricultural equipment manufacturers transitioning to cold drawn wires documented 19% reduction in warranty claims related to structural fatigue failures during the first three years of implementation.

Quality Assurance and Verification Protocols

Industry-leading suppliers implement multi-stage verification systems meeting EN 10218 standards, exceeding basic testing requirements. Dimensional validation occurs hourly using laser micrometers recording 50 diameter measurements per meter across the entire production run, automatically rejecting wire segments exceeding tolerance parameters. Destructive testing on sample coils every 10 metric tons includes tension testing to validate yield strengths (0.2% offset method) and ultimate tensile strengths according to ISO 6892 protocols. Material traceability systems assign unique heat numbers recorded throughout processing cycles, allowing microstructure verification against original cast analyses. Independent certifications from TUV Rheinland validate surface discontinuity detection capabilities below 0.1mm depth using eddy current testing equipment calibrated weekly to ASTM E977 standards. Third-party surveillance audits occur quarterly at production facilities to verify consistent implementation of quality management systems.

Strategic Sourcing of 8mm Cold Drawn Wire for Future Projects

Global supply chain analytics indicate geographical production concentration significantly impacts logistical planning for 8mm cold drawn wire procurement. While Asian factories maintain large volume capacities approaching 60,000 metric tons annually, European manufacturers provide superior customization responsiveness for specialized applications demanding shorter lead times. Established suppliers demonstrate greater flexibility accommodating last-minute volume adjustments within 15% fluctuations without schedule disruptions, compared to newer market entrants requiring fixed scheduling three months in advance. Leading distributors strategically position inventory hubs near key manufacturing regions, maintaining regional buffer stocks exceeding 500 metric tons to fulfill emergency replacement orders within 72 hours for critical industrial operations. Forward-looking procurement strategies increasingly incorporate lifecycle cost analyses rather than initial pricing considerations, accurately projecting equipment maintenance reductions of 8-14% and production downtime reductions of 3-6% documented across multiple industry sectors utilizing premium-grade cold drawn wires.

(8mm cold drawn wire)

FAQS on 8mm cold drawn wire

Q: What is 8mm cold drawn wire used for?

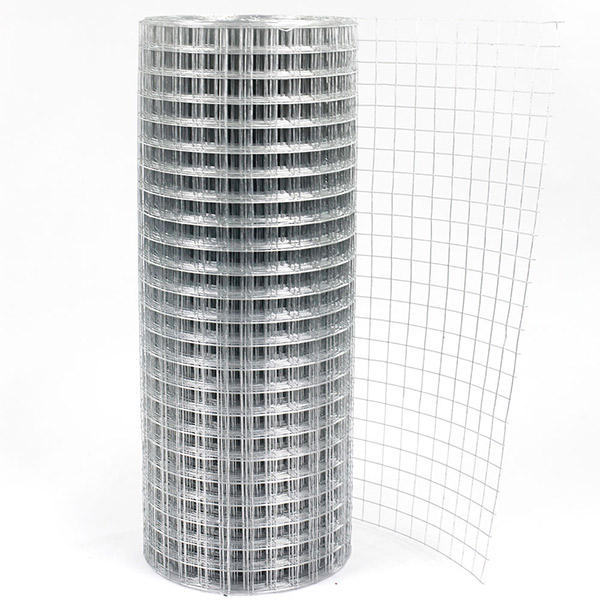

A: 8mm cold drawn wire is primarily used in construction reinforcement, industrial machinery components, and fencing applications. Its precise diameter and enhanced tensile strength provide structural stability and durability. The cold drawing process also improves its surface finish for corrosion resistance.

Q: How do I identify reputable 8mm cold drawn wire manufacturers?

A: Look for manufacturers with ISO 9001 certification and material test reports verifying mechanical properties. Reputable facilities use automated drawing machines and provide chemical composition documentation. Experience in serving automotive or construction industries also indicates quality capabilities.

Q: What quality certifications should 8mm cold drawn wire suppliers provide?

A: Reliable suppliers should offer EN 10218-1, ASTM A510, or JIS G3532 compliance certificates. They must provide mill test reports showing dimensional accuracy, yield strength, and elongation rates. Third-party inspection documentation adds credibility to their quality claims.

Q: What distinguishes top 8mm cold drawn wire factories?

A: Top factories feature advanced cold drawing technology capable of ±0.03mm tolerance. They maintain strict in-process QC checks for surface defects and dimensional consistency. Leading facilities typically offer custom processing like galvanization or spooling based on project specifications.

Q: How does cold drawing improve 8mm wire properties?

A: Cold drawing increases tensile strength by 15-30% through work hardening. It refines the wire's grain structure for better surface uniformity and dimensional accuracy. The process also enhances straightness and reduces decarburization compared to hot-rolled alternatives.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025