Nov . 02, 2024 08:00 Back to list

oem concrete reinforcement wire mesh

The Importance of OEM Concrete Reinforcement Wire Mesh in Construction

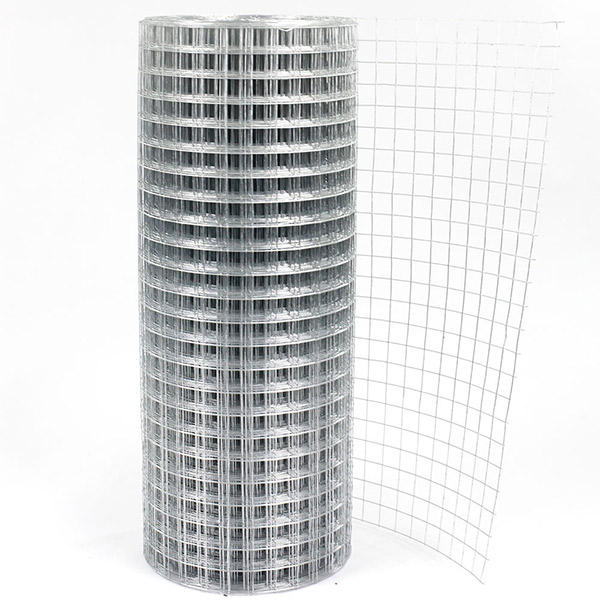

In the modern construction industry, the emphasis on structural integrity and durability is paramount. An essential component that contributes to this aspect is concrete reinforcement, and among the most effective materials used for this purpose is OEM concrete reinforcement wire mesh. This versatile product plays a crucial role in enhancing the strength and longevity of concrete structures, making it a vital consideration for builders and engineers alike.

OEM, or Original Equipment Manufacturer, wire mesh refers to concrete reinforcement mesh that is produced according to specific standards and specifications of construction companies or other end users

. This customization ensures that the wire mesh meets the unique demands of various construction projects, ranging from residential buildings to large-scale infrastructure like bridges and highways.One of the primary functions of reinforcement wire mesh is to provide tensile strength to concrete, which is typically strong in compression but weak in tension. When incorporated into concrete, the wire mesh helps to distribute stresses more evenly, preventing cracks and structural failures that could arise from improper load distribution. This is particularly important in areas subject to heavy loads, temperature fluctuations, or seismic activity.

The composition of OEM concrete reinforcement wire mesh typically consists of high-strength steel wires that are arranged in a grid pattern. These wires are usually welded at their intersections, creating a robust framework that can effectively resist tensile forces. Furthermore, the use of galvanized or coated wire options enhances the mesh's resistance to corrosion, extending the lifespan of the reinforced concrete structure and reducing maintenance costs.

oem concrete reinforcement wire mesh

One of the significant advantages of using OEM wire mesh over traditional reinforcement methods, such as rebar, is its ease of installation. The mesh sheets can be quickly laid out on site, saving both time and labor costs. This efficiency translates into quicker project completion times, which is a crucial aspect in the competitive construction industry. Additionally, the uniformity of wire mesh ensures a more consistent distribution of reinforcement throughout the poured concrete, contributing to overall structural stability.

Another key benefit of OEM concrete reinforcement wire mesh is its adaptability to various project requirements. Manufacturers can produce mesh in different sizes, shapes, and wire thicknesses, allowing engineers to specify the right type of mesh for each unique application. This flexibility not only enhances the performance of the concrete but also provides builders with more design options.

Moreover, the use of OEM products can often lead to cost savings. By sourcing reinforcement wire mesh directly from manufacturers, construction companies can minimize overhead costs and negotiate favorable terms. This partnership can foster innovation in product design, resulting in better materials and techniques that can revolutionize building practices.

In conclusion, OEM concrete reinforcement wire mesh is an indispensable element in modern construction practices. Its ability to enhance structural integrity, ease of installation, adaptability, and potential for cost-saving makes it a popular choice among builders and engineers. As the construction industry evolves, the demand for high-quality and reliable reinforcement materials like wire mesh will continue to grow, ensuring that our buildings and infrastructure remain safe, durable, and resilient for years to come. Investing in OEM concrete reinforcement wire mesh is not just a choice; it's a commitment to excellence in construction.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025