јун . 10, 2025 01:08 Back to list

Chain Link Fence Gates - Durable & Secure Access Solutions

- Understanding the Importance of Chain Link Fence Gates

- Market Statistics Driving Gate Demand

- Engineering Superiority in Modern Gate Systems

- Leading Gate Manufacturers Comparison

- Customization Options for Varied Requirements

- Installation Scenarios Across Multiple Sectors

- Selecting Trusted Chain Link Fence Gate Suppliers

(chain link fence gates)

Understanding the Importance of Chain Link Fence Gates

Industrial facilities face significant security challenges without proper perimeter solutions. Chain link fence gates serve as critical control points, preventing unauthorized entry while allowing smooth flow of authorized personnel and vehicles. A robust gate system reduces vulnerability points at access locations. Effective double-swing configurations accommodate forklifts with turning radii up to 12 feet, while sliding variations save space for properties with limited clearance. Beyond security, properly engineered gates withstand frequent operations without sagging; hinge mechanisms must endure minimum 50,000 cycles. Professional maintenance every six months prevents friction issues at pivot points. Property managers increasingly emphasize these access solutions for liability reduction.

Market Statistics Driving Gate Demand

Recent industry analysis indicates expanding security concerns have driven double-digit growth for perimeter security systems. The global fencing market reached $27.8 billion last year, with chain link systems holding 32% segment share. Infrastructure projects account for 45% of gate purchases, particularly transportation networks where fencing must resist corrosion in varying climates. Supply chain disruptions increased material costs by 18%, yet demand persists—new factory constructions report allocating 8-12% of security budgets specifically for access gates. Schools prioritize safety upgrades with reinforced gate models, creating sustained demand. Market projections show continued 6.7% annual expansion through 2028.

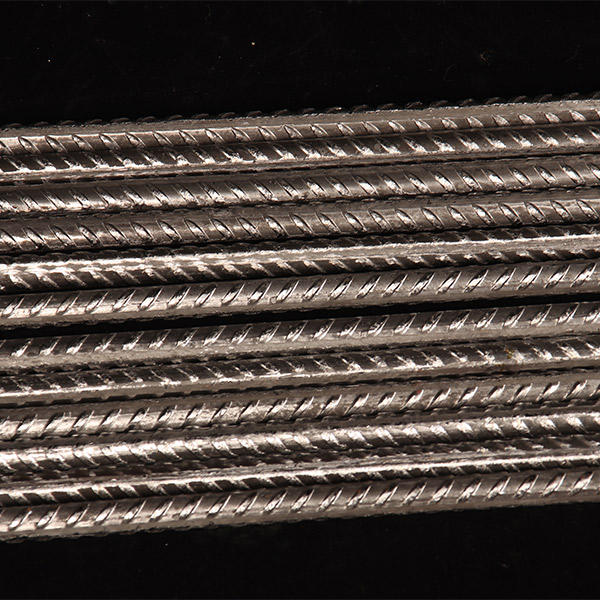

Engineering Superiority in Modern Gate Systems

Technological innovations transform basic fencing into sophisticated security interfaces. Frame construction now utilizes 12-gauge steel rather than standard 14-gauge for enhanced structural integrity under stress tests exceeding 250 pounds per square inch. Hot-dip galvanization provides corrosion resistance even after 2,000 hours in salt spray chambers. Leading designs incorporate double-locking mechanisms that thwart leverage attacks common to single-lock systems. Advanced self-aligning hinges compensate for ground shifts and prevent sagging during temperature fluctuations from -30°F to 120°F. Cantilevered sliding models eliminate ground tracks that accumulate debris in industrial settings. Post-installation tension adjustments maintain structural performance decades after deployment.

Leading Gate Manufacturers Comparison

| Manufacturer | Price Range | Production Capacity (gates/month) | Warranty Coverage | Lead Time (weeks) | Material Standard |

|---|---|---|---|---|---|

| Perimeter Solutions | $$$-$$$$ | 2,400 | 20 years frame / 10 years moving parts | 4-6 | ASTM F900 compliant |

| SecureLink Industries | $$-$$$ | 3,800 | 15 years frame / 7 years hardware | 2-4 | Galvanized steel with additional polymer coating |

| Fortress Gate Co. | $$$$ | 950 | Lifetime frame / 12 years mechanisms | 8-10 | AISI Type 304 stainless components |

| National Barrier Systems | $$ | 4,500 | 10 years comprehensive | 1-3 | Standard galvanized steel |

Customization Options for Varied Requirements

Standard gate designs rarely address unique site challenges, making customization essential. Width variations span from pedestrian models (3-4 feet) to heavy vehicle access units exceeding 20 feet. Height modifications maintain fence integrity with consistent mesh patterns from 4 to 12 feet. Facilities managers often specify heavy-duty mesh options with vinyl coating for abrasion resistance in industrial environments. Safety-conscious clients add anti-climb designs with 30-degree top slopes to deter scaling attempts. Coastal properties require salt spray-resistant hardware achieving ASTM B117 protection thresholds. Manufacturers integrate warning signage directly into gate designs and develop specialized locking systems that accommodate keycard access. Production facilities increasingly request integral personnel gates within larger vehicle access points.

Installation Scenarios Across Multiple Sectors

Different industries implement chain link gates based on specific operational profiles. Educational institutions installed reinforced swing units at 4,200 schools last year nationwide following new safety standards, prioritizing controlled visitor access points. Manufacturing facilities require sliding gates with ground clearance exceeding 8 inches for debris clearance in high-traffic loading docks. Correctional facilities utilize multi-point locking systems with redundant mechanisms for maximum security access control. Utility companies specify double-leaf designs with 16-gauge framing for substation perimeters in high-wind regions. Military applications employ custom 14-gauge solutions with specialized coatings resisting chemical exposure. Residential compounds increasingly choose aesthetic vinyl-clad alternatives matching architectural themes without compromising security thresholds.

Selecting Trusted Chain Link Fence Gate Suppliers

Evaluating perimeter security partners requires thorough due diligence before procurement decisions. Established chain link fence gates

suppliers maintain documented quality control processes that exceed ASTM F668 standards for mesh integrity and fastener security. Review third-party certifications like ISO 9001 manufacturing certifications indicating consistent production protocols. Physical product sampling verifies actual versus claimed specifications—particularly galvanization thickness measured in microns. Leading factories perform destructive testing on random units monthly, documenting structural failure points. Experienced suppliers provide comprehensive installation supervision rather than basic delivery services. Maintenance package availability remains critical; industry leaders report 92% client retention when offering annual service agreements versus basic warranty fulfillment.

(chain link fence gates)

FAQS on chain link fence gates

Q: What customization options do chain link fence gates manufacturers offer?

A: Manufacturers typically provide customizable gate heights, widths, and frame gauges to suit project needs. You can also choose various finishes like galvanized, powder-coated, or vinyl-coated options. Self-closing mechanisms and specialized hardware are additional customizable features available.

Q: How do I identify reliable chain link fence gates suppliers?

A: Reliable suppliers have ISO certifications, material test reports, and verifiable industry experience. Always request physical product samples and check online reviews about delivery timelines. Additionally, inquire about their warranty coverage and post-purchase technical support services.

Q: What materials are used in chain link fence gates factories?

A: Factories primarily use galvanized steel wire (ASTM A641 standard) or commercial-grade aluminum for corrosion resistance. Frames are constructed from heavy-duty steel tubing (14-16 gauge thickness), while hardware like hinges and latches feature zinc-plated or stainless steel components. Mesh sizes typically range from 1-3/8" to 2".

Q: What safety features come with industrial chain link fence gates?

A: Industrial gates include spring-loaded self-latching systems that automatically secure the gate. Many feature anti-lift pivot mechanisms and tamper-proof bolts to prevent forced entry. Top suppliers also offer OSHA-compliant designs with climb-resistant vertical blade extensions.

Q: What certifications should chain link fence gates manufacturers have?

A: Reputable manufacturers hold ISO 9001 quality management certification and ASTM compliance certificates. For perimeter security projects, look for manufacturers with DoD/CPPAH and UL 325 safety standard accreditation. Proper CRRC ratings for solar reflectance are also important for specialized applications.

-

Industrial-Grade Welded Wire Mesh for Factories & Suppliers | Durable

NewsJul.25,2025

-

Precision Cold Drawn Wire: High Strength & Durability Solutions

NewsJul.25,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025