Tet . 22, 2024 00:54 Back to list

stud bolt astm a193 b16 supplier

Understanding Stud Bolt ASTM A193 B16 A Complete Guide for Suppliers

Stud bolts are essential components commonly used in mechanical assemblies, particularly in high-pressure applications such as pipelines, pressure vessels, and heavy machinery. When discussing stud bolts, one specific standard that stands out is ASTM A193, which governs the material requirements, mechanical properties, and testing methods for various grades of bolts intended for high-temperature or high-pressure service. Among these grades, A193 B16 is a notable choice for many industrial applications.

What is ASTM A193 B16?

ASTM A193 B16 is a specification designed for high-strength bolts that are made from alloy steel. The B16 designation indicates a specific grade that exhibits excellent mechanical properties, including high tensile strength and good ductility at elevated temperatures. This makes it particularly suitable for use in environments that experience heat-induced stress, such as those found in power plants, steam pipelines, and chemical processing facilities.

Key Features of A193 B16 Stud Bolts

1. Material Composition A193 B16 bolts are typically made from chromium-molybdenum alloy steel, which confers exceptional strength and temperature resistance. This alloying process ensures that the bolts maintain their integrity even under extreme conditions.

2. Mechanical Properties To meet the ASTM A193 B16 requirements, the studs must have a minimum yield strength of 105 ksi (724 MPa) and a minimum tensile strength of 125 ksi (862 MPa). Such strong mechanical properties ensure reliability in high-stress applications.

stud bolt astm a193 b16 supplier

3. Heat Treatment In order to achieve the desired mechanical properties, A193 B16 bolts undergo a heat treatment process. This treatment not only enhances strength but also improves the microstructure of the steel, leading to increased fatigue resistance.

4. Corrosion Resistance Depending on the application, an additional coating or treatment may be applied to the studs to provide resistance to corrosion, thereby extending their service life.

Choosing a Reliable Supplier

For engineers and procurement managers, finding a reliable supplier of ASTM A193 B16 stud bolts is crucial. Suppliers should be able to provide detailed certification and documentation that confirm the bolts meet ASTM specifications. Moreover, selecting a supplier with a strong reputation in the industry ensures that the products are of high quality and fully tested.

Furthermore, suppliers should offer guidance on proper handling and installation to maximize the performance and longevity of the stud bolts. Training and technical support can also be beneficial, as they help ensure that the assembly process adheres to industry best practices.

Conclusion

In summary, ASTM A193 B16 stud bolts are integral to industries requiring reliable fastening solutions under high-temperature and high-pressure conditions. By sourcing these essential components from reputable suppliers, businesses can ensure their operations run smoothly and safely. Whether in power generation, chemical processing, or any other demanding environment, the right stud bolt can make all the difference.

-

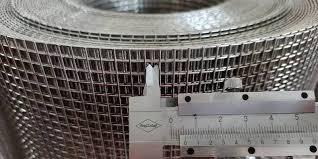

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025