Sht . 13, 2024 08:18 Back to list

oem 4mm cold drawn wire

Understanding OEM 4mm Cold Drawn Wire

In the realm of manufacturing and construction, the demand for high-quality materials is ever-present. One such material that has gained prominence is the OEM (Original Equipment Manufacturer) 4mm cold drawn wire. This specialized wire is produced through a meticulous process that enhances its properties, making it suitable for various applications across diverse industries.

What is Cold Drawing?

Cold drawing is a metalworking process that involves pulling a metal wire through a die to reduce its diameter while simultaneously increasing its length. The process occurs at room temperature, which helps preserve the material's strength and structural integrity. By drawing the wire to a specific diameter, manufacturers can achieve precise tolerances and improved mechanical characteristics.

Advantages of 4mm Cold Drawn Wire

1. Enhanced Strength The cold drawing process increases the tensile strength of the wire. As the material is deformed, its grain structure becomes finer and more aligned, ultimately leading to improved strength properties. This makes 4mm cold drawn wire particularly suitable for applications where strength is paramount, such as in construction and automotive manufacturing.

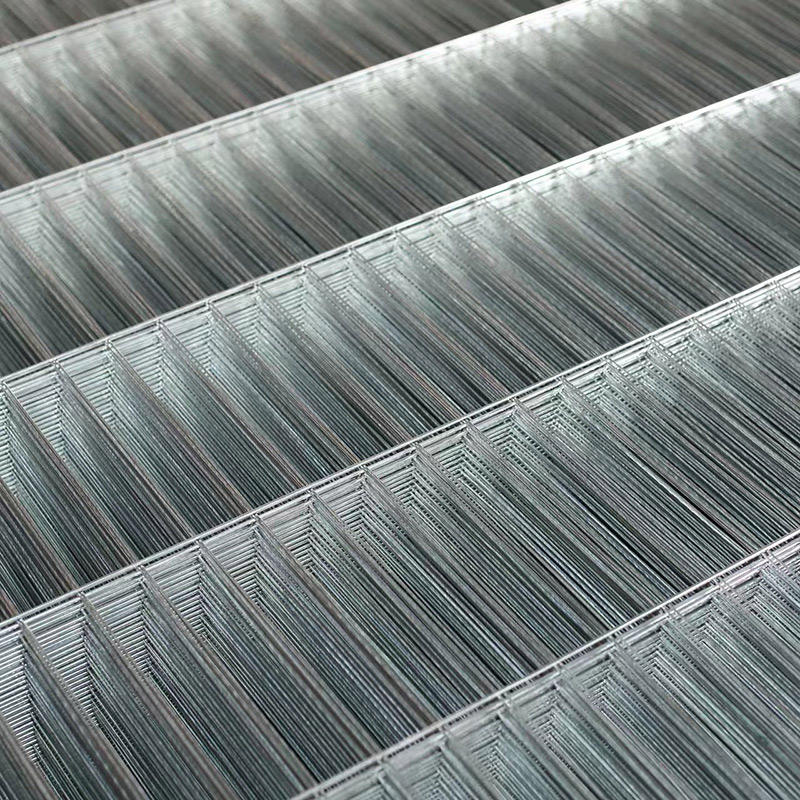

2. Uniform Diameter One of the most significant benefits of cold drawn wire is its uniform diameter. This precision in size ensures that the wire can be safely and effectively used in applications involving tight tolerances. It reduces the risk of defects in the final product, making it ideal for OEM requirements.

oem 4mm cold drawn wire

3. Improved Surface Finish Cold drawn wire typically has a smoother surface finish compared to hot-rolled wire. This is particularly advantageous for applications where the wire is visible or needs to be painted or coated, as it allows for better adhesion of coatings and improved aesthetic appeal.

4. Versatility OEM 4mm cold drawn wire can be used in a wide range of applications, from producing springs and cables to reinforcement in concrete structures. Its versatility makes it a go-to material for engineers and designers looking for reliable wire solutions.

Applications of OEM 4mm Cold Drawn Wire

The versatility of OEM 4mm cold drawn wire allows it to serve various industries, including

- Construction Used in reinforcement bars, cables, and mesh for concrete structures. - Automotive Employed in making springs, cables, and other components where strength and precision are critical. - Manufacturing Utilized in producing specialized fasteners and fixtures that require high strength and durability. - Electrical Used in producing wire harnesses and other electrical components.

Conclusion

In conclusion, OEM 4mm cold drawn wire stands out as a crucial material in modern manufacturing and construction. Its enhanced strength, uniformity, and improved surface finish make it a preferred choice for various applications across different industries. As manufacturers continue to seek solutions that meet high-quality standards, cold drawn wire will undoubtedly remain a key player in the landscape of industrial materials. Understanding its capabilities allows businesses to make informed decisions, ensuring the success of their projects and products.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025