Jan . 02, 2025 09:26 Back to list

2mm galvanized iron wire factories

The Evolution and Significance of 2mm Galvanized Iron Wire Factories

In the modern industrial landscape, galvanized iron wire has become an indispensable material, utilized in a plethora of applications ranging from construction to agriculture. Among the various dimensions of galvanized wires, the 2mm variant has gained particular prominence due to its strength, durability, and versatility. This article delves into the significance of factories producing 2mm galvanized iron wire, examining their roles in the economy, industry, and environmental sustainability.

Understanding Galvanization

Galvanization is the process of coating iron or steel with zinc to prevent rusting and corrosion. The hot-dip galvanization technique is commonly employed, where the metal is submerged in molten zinc, resulting in a robust protective layer. This process not only enhances the lifespan of the wire but also supports structural integrity, making galvanized wires ideal for various applications.

The Importance of 2mm Galvanized Iron Wire

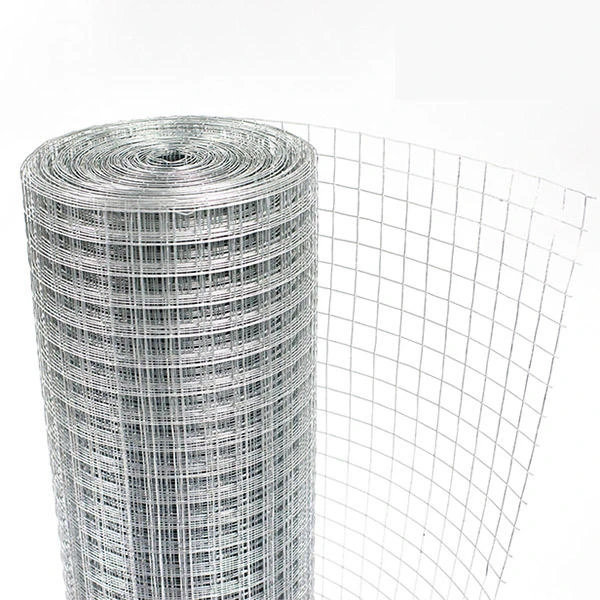

The 2mm galvanized iron wire is widely used for fencing, binding, and construction support. Its robust construction makes it suitable for tension applications, while its resistance to environmental factors ensures longevity. Fencing is one of the primary applications of 2mm galvanized wire, which serves as a deterrent against wildlife and is also employed in agricultural settings to protect crops. Its use in construction, particularly in reinforcing concrete structures, is equally crucial, as it contributes to the overall strength of a building.

Moreover, the 2mm variant is favored due to its balance of flexibility and strength. It's thick enough to withstand tension and stress while remaining malleable enough to be shaped and bent to fit specific applications.

The Role of Factories in Economic Development

Factories producing 2mm galvanized iron wire play a vital role in economic development. They provide employment opportunities and contribute to the local and national economy through the manufacturing process. These factories often employ a range of skilled and unskilled labor, helping to uplift communities by providing livelihoods. Furthermore, the production of galvanized wire stimulates ancillary industries, including transportation, logistics, and raw material suppliers.

2mm galvanized iron wire factories

As the construction and agricultural sectors continue to grow globally, the demand for galvanized iron wire is expected to rise. Factories that adapt to meet this demand, through innovation and efficiency, are crucial for sustaining industrial growth.

Environmental Considerations

An increasingly important aspect of production today is environmental sustainability. The production of galvanized wire involves processes that, if not managed responsibly, can have adverse effects on the environment. However, leading factories are incorporating eco-friendly practices to minimize their carbon footprint. This includes recycling water used during the galvanization process, reducing energy consumption through efficient machinery, and ensuring proper disposal of waste materials.

Many modern galvanized wire manufacturers are also focusing on creating products that are 100% recyclable. This aligns with global trends toward sustainability and responsible manufacturing. By promoting recycling and utilizing sustainable practices, these factories can have a reduced impact on the environment while meeting the growing market demands.

Embracing Innovation

As with many sectors, the galvanized wire industry is evolving through technological advancements. Factories are increasingly adopting automated production lines to enhance efficiency and reduce labor costs. Innovations in coating processes and machinery have also led to improvements in product quality and consistency.

Moreover, the integration of Industry 4.0 principles, like IoT (Internet of Things) and data analytics, allows manufacturers to monitor production processes in real time. This shift enables them to optimize operations, reduce waste, and improve overall productivity.

Conclusion

In conclusion, 2mm galvanized iron wire factories play a pivotal role in various sectors, contributing to economic growth, environmental sustainability, and technological advancement. As demand for galvanized wire continues to rise, these factories must balance efficiency with responsibility, ensuring that they not only meet present needs but also pave the way for a sustainable future. By focusing on innovation and eco-friendly practices, they can secure their place in a rapidly evolving marketplace while contributing positively to society and the environment.

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025